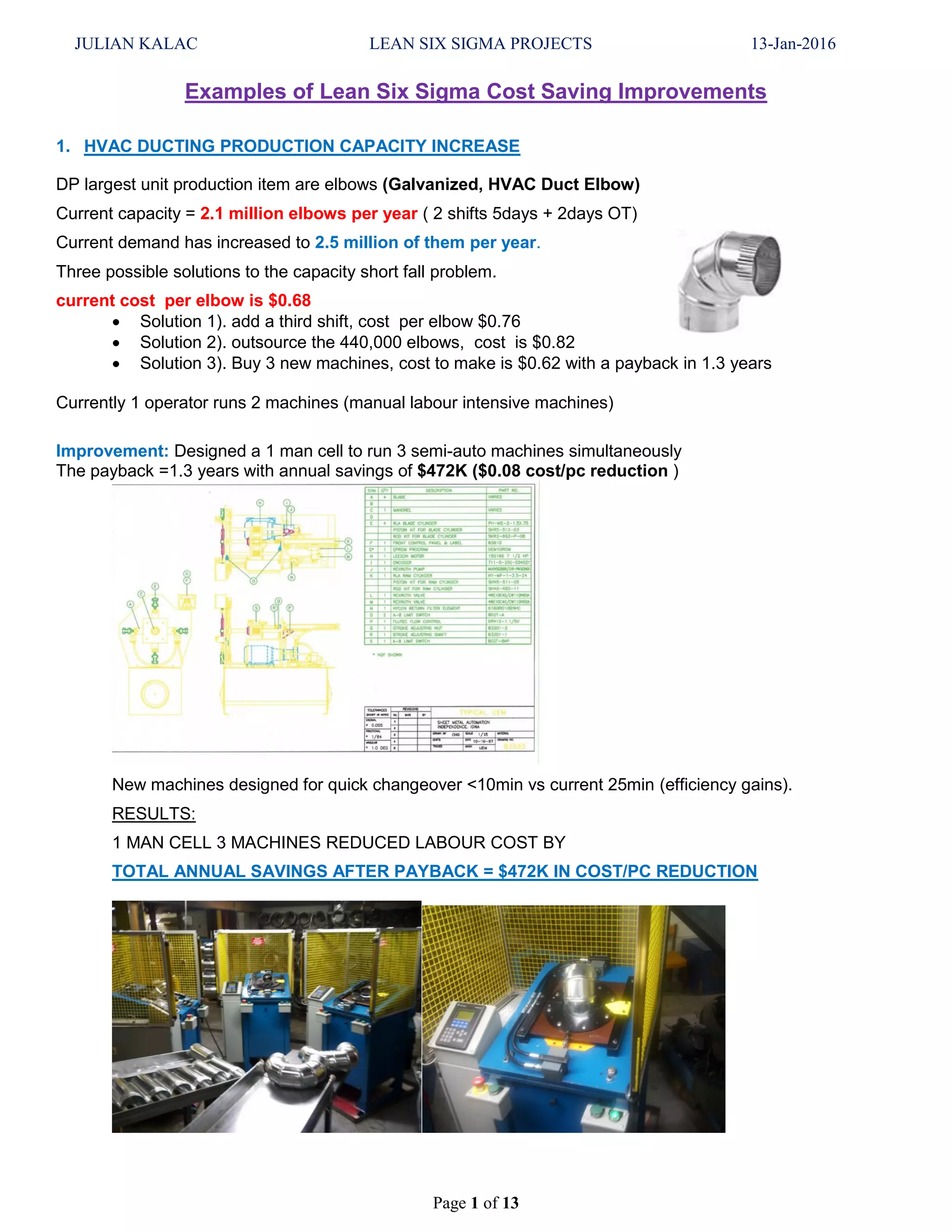

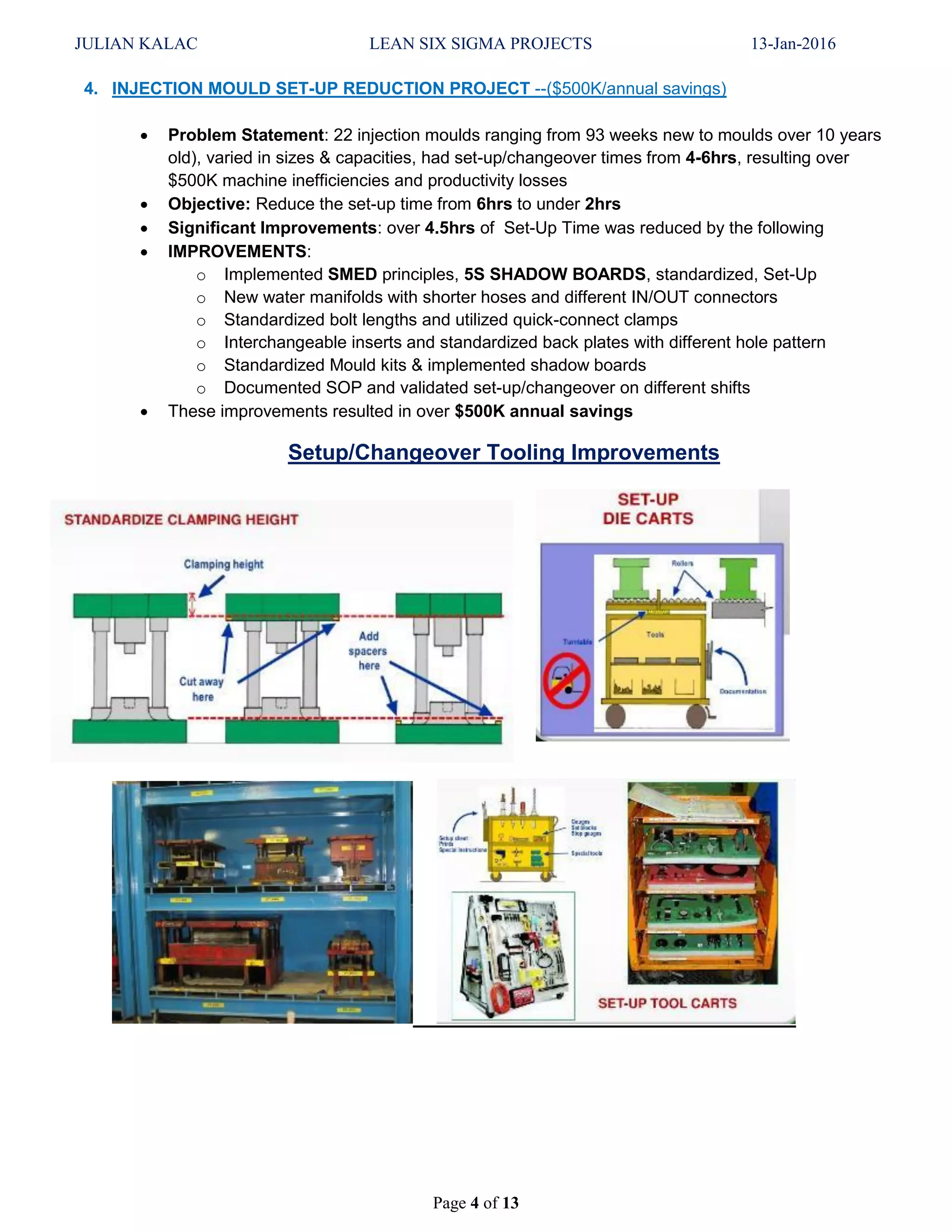

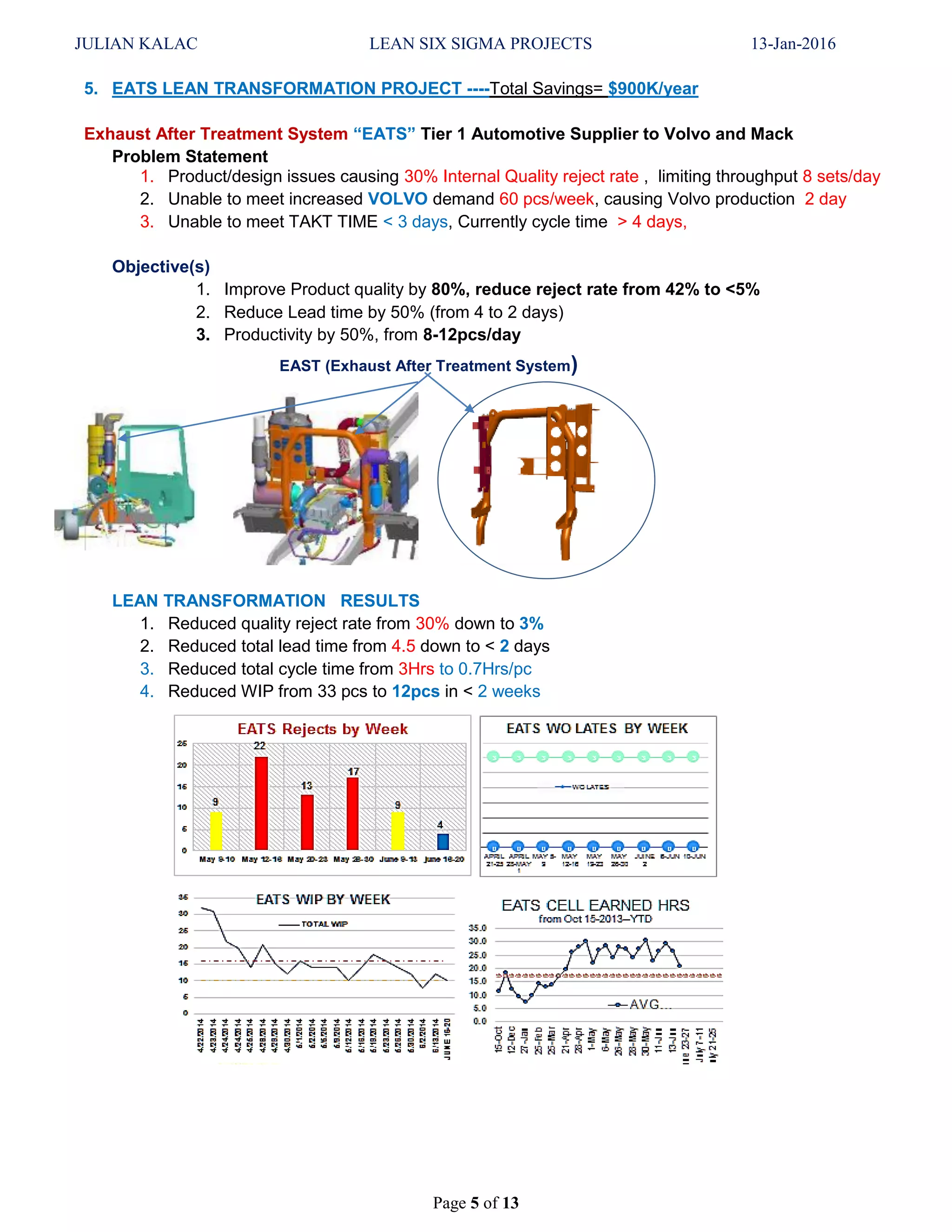

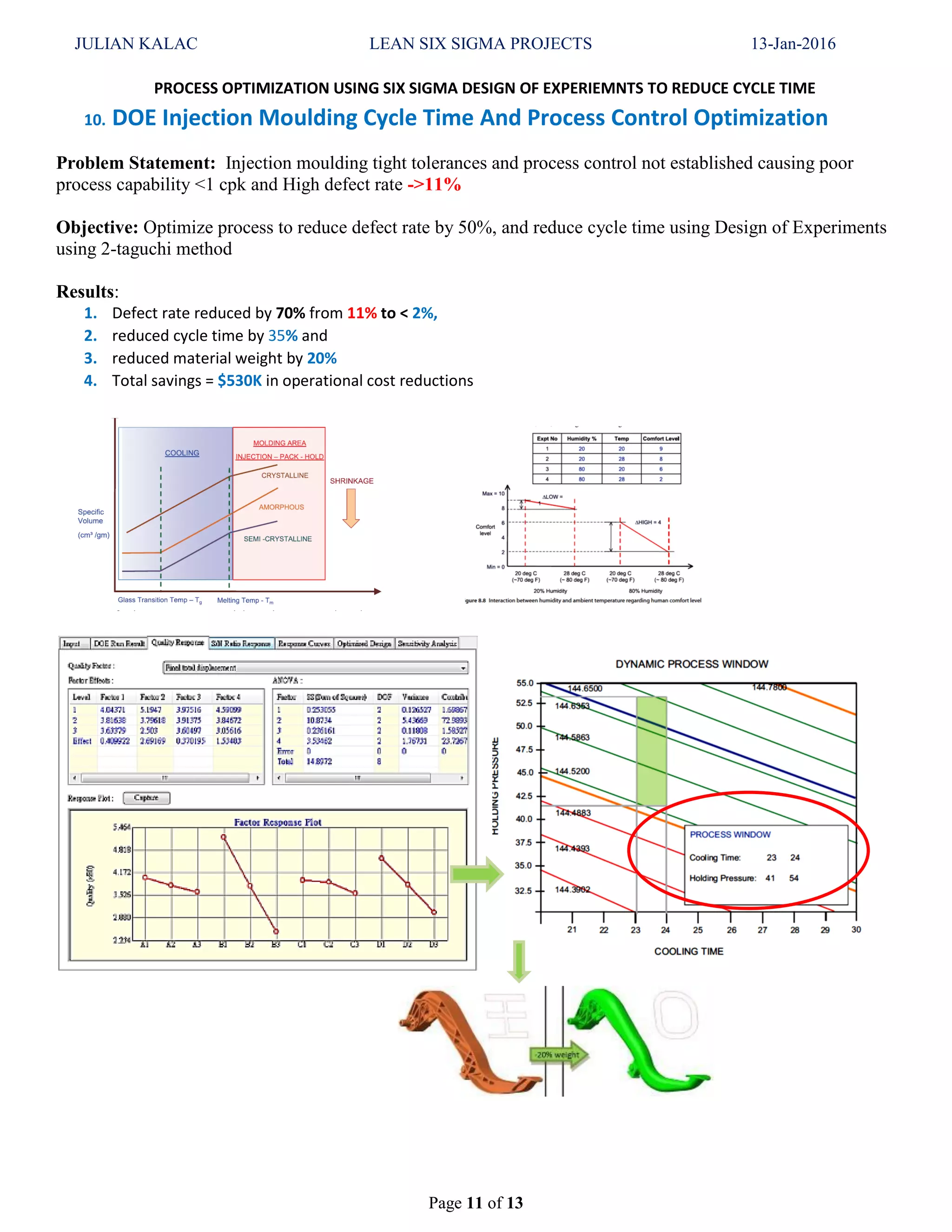

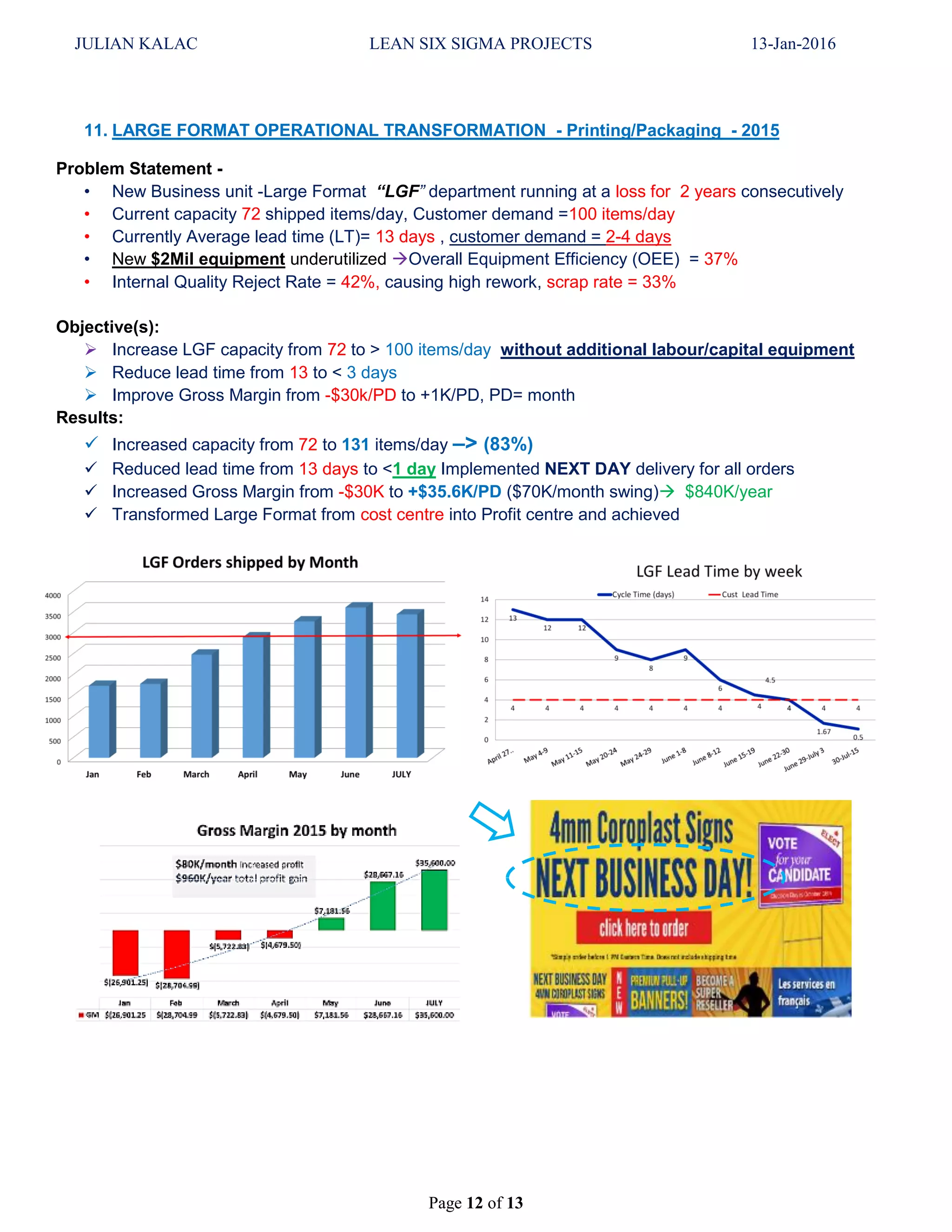

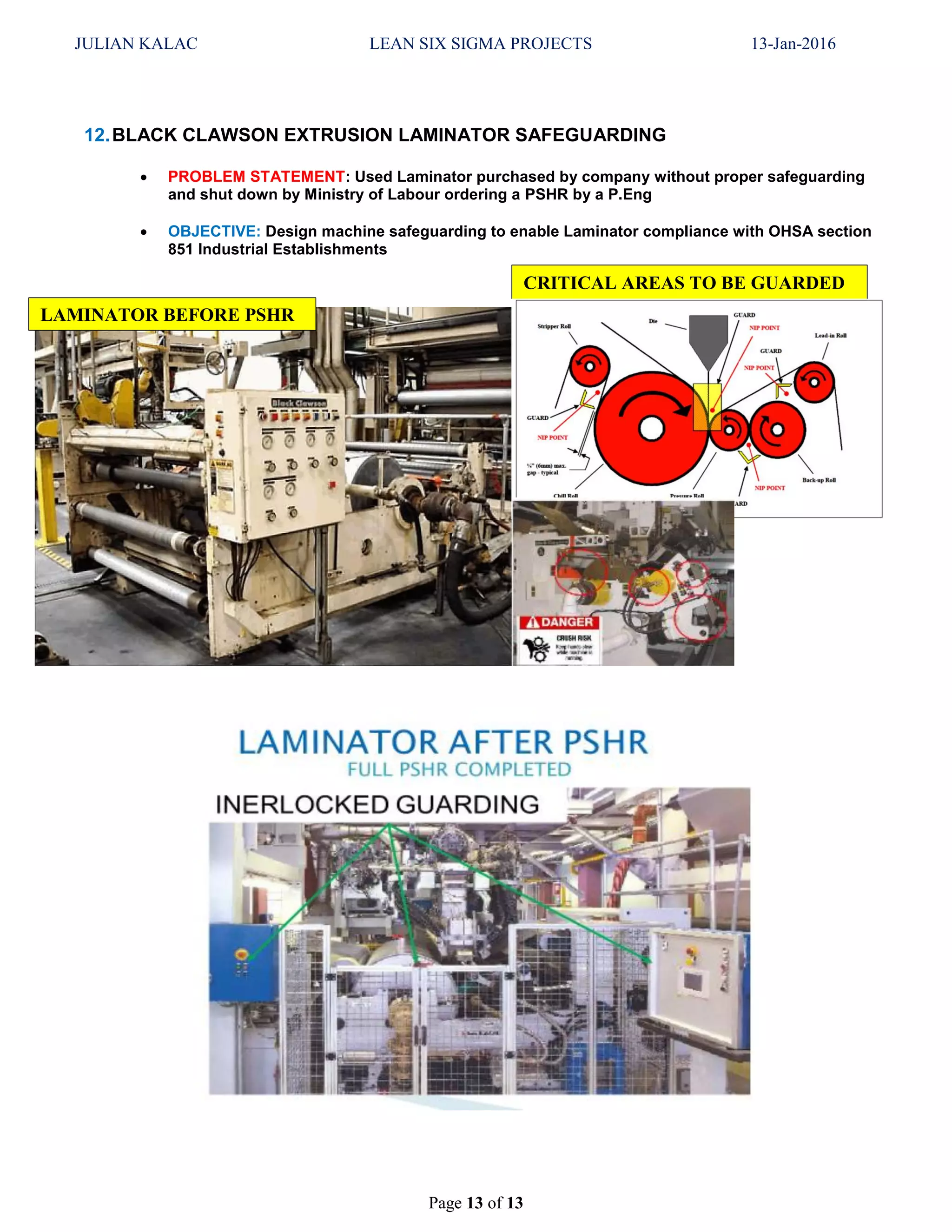

The document provides 12 examples of Lean Six Sigma projects that resulted in cost savings through process improvements. The first example describes a project that increased production capacity of HVAC duct elbows by designing a one-man cell to run three semi-automatic machines simultaneously, achieving annual savings of $472k. Another project reduced robot welding setup time from 38 minutes to zero by designing modular fixtures, achieving annual savings of $650k. A third project converted batch production to continuous flow, increasing shift capacity by 82% and eliminating the need for overtime.