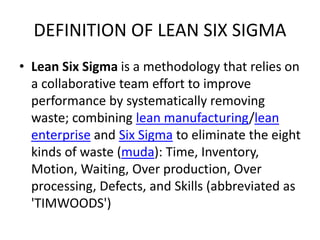

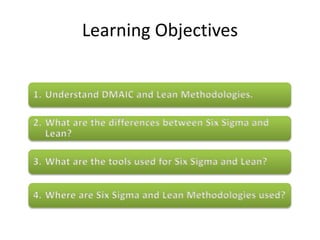

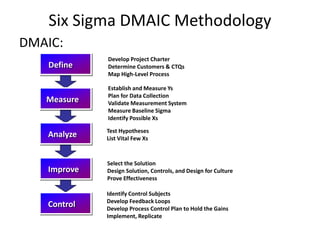

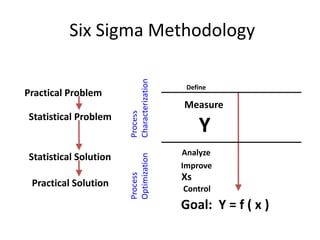

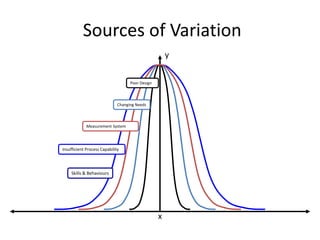

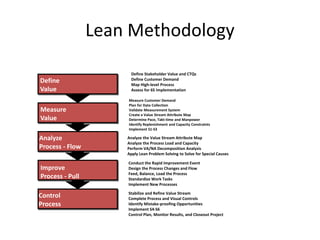

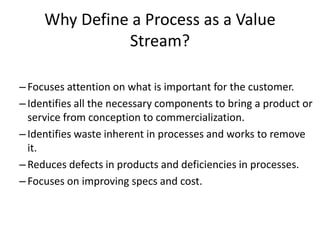

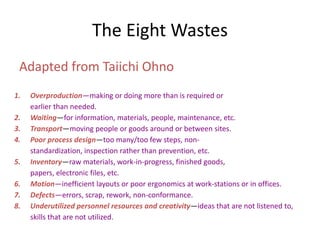

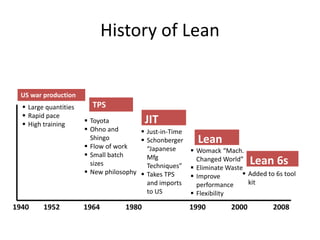

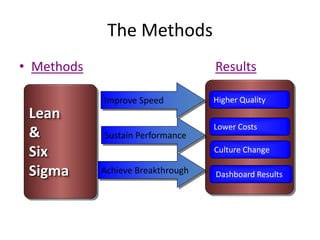

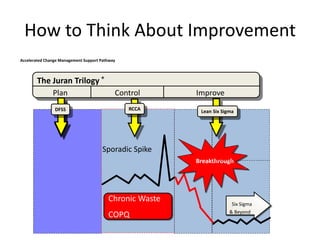

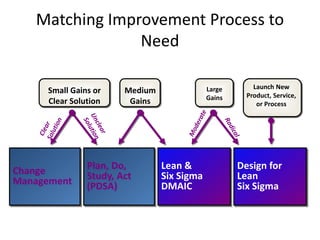

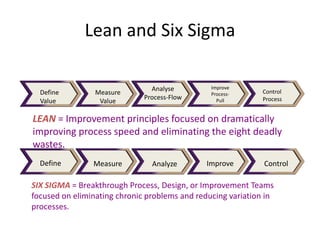

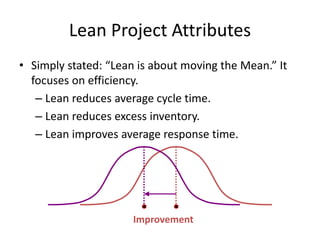

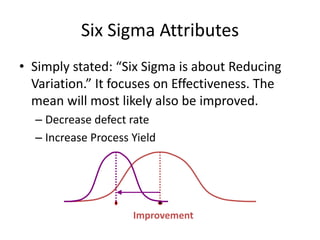

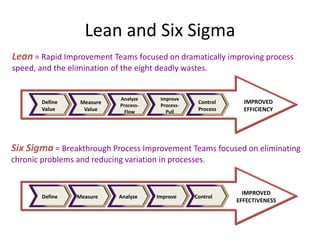

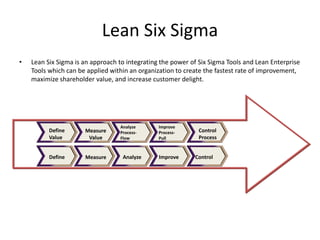

This document provides an overview of Lean Six Sigma and compares it to Lean and Six Sigma methodologies. It defines Lean Six Sigma as an approach that combines Lean manufacturing/Lean enterprise tools and Six Sigma tools to eliminate waste and reduce variation. It describes the DMAIC process used in Six Sigma and the Lean methodology of defining value streams. Key differences between Lean and Six Sigma are highlighted, such as Lean focusing on efficiency and reducing cycle time/inventory while Six Sigma focuses on effectiveness and reducing defects/variation. The document recommends starting with Lean projects to streamline processes before tackling more complex Six Sigma projects to eliminate chronic problems.