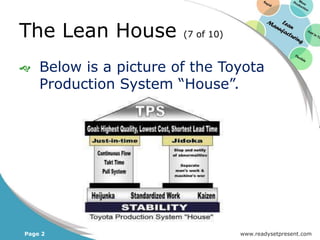

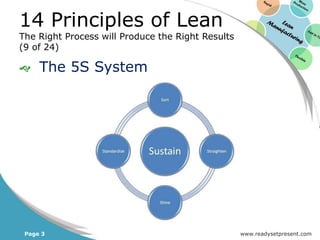

The document is a presentation on lean manufacturing principles from the website ReadySetPresent.com. It covers topics such as the Toyota Production System house model, the five S system, the two main focuses of lean being continuous improvement and respect for people, the seven types of waste, kanban pull systems, stopping problems to get quality right the first time, becoming a learning organization through reflection and improvement, and Japanese lean terms. The presentation provides over 300 slides on lean foundations and principles.