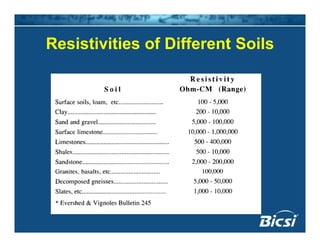

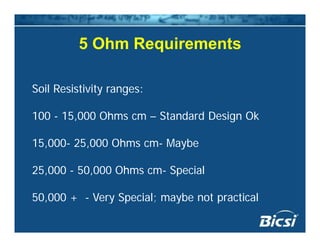

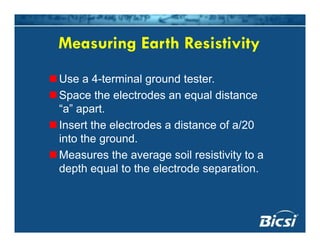

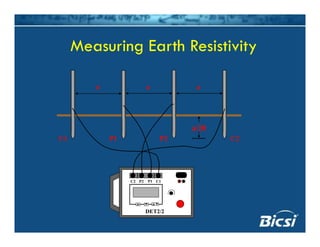

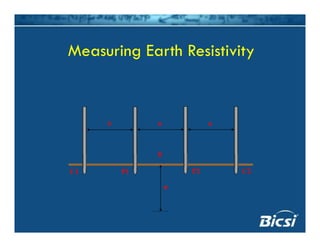

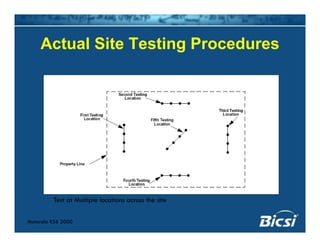

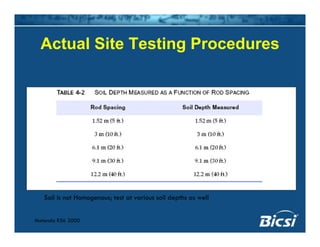

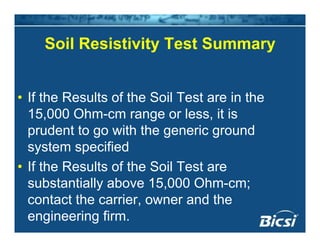

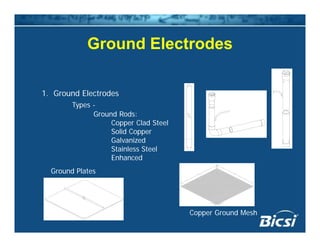

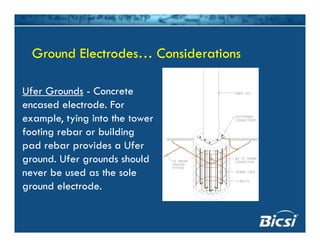

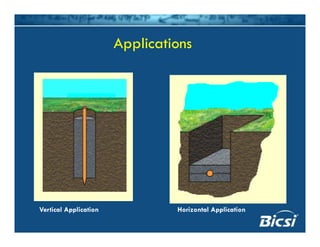

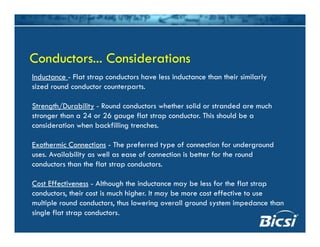

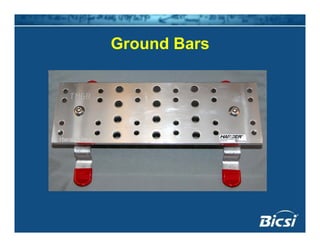

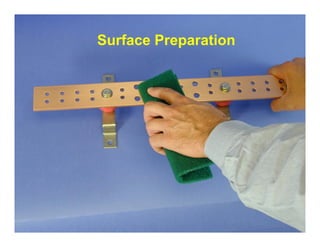

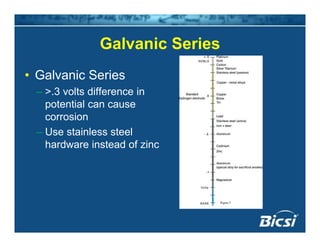

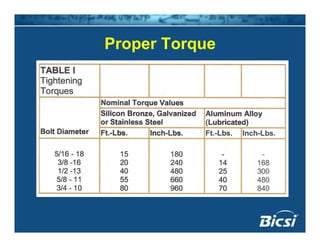

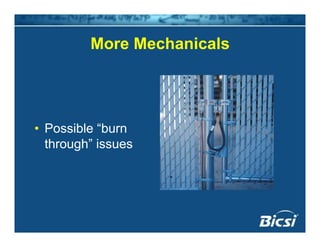

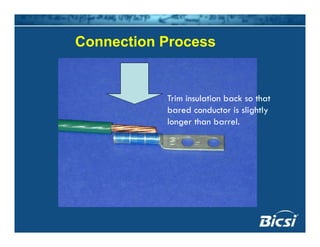

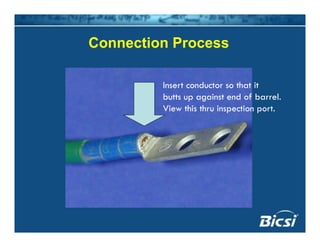

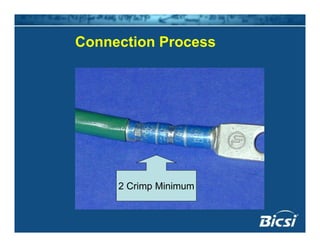

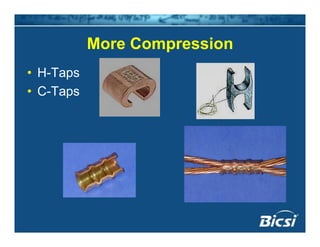

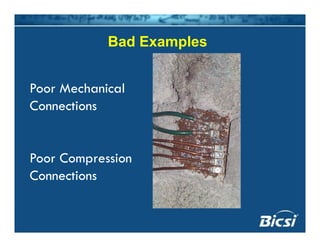

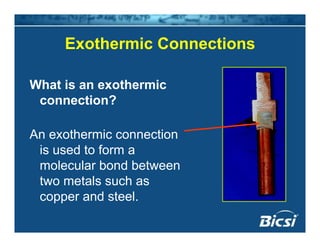

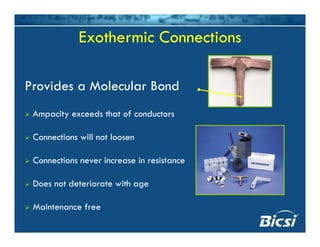

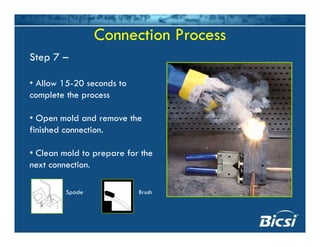

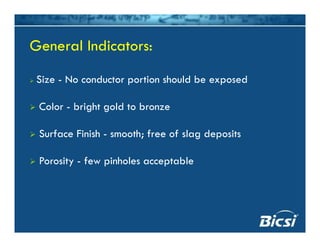

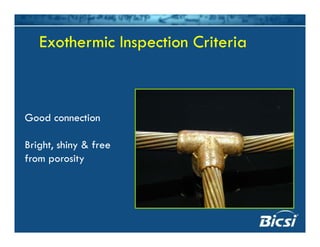

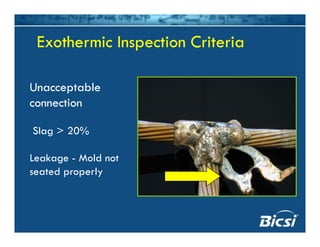

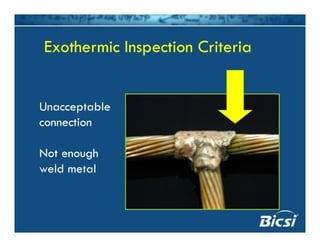

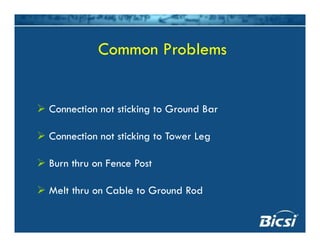

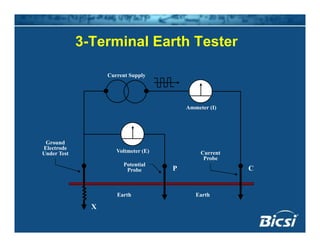

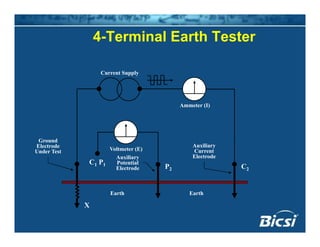

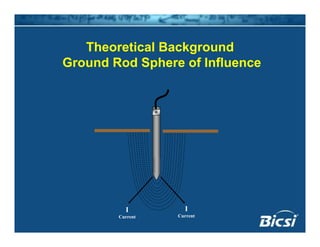

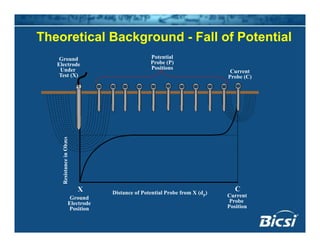

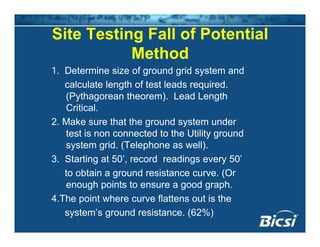

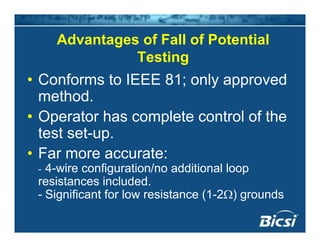

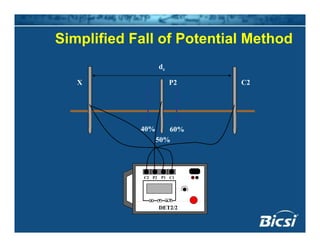

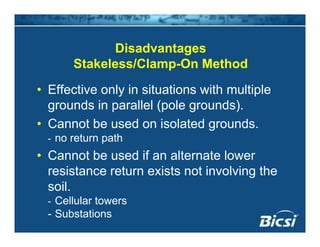

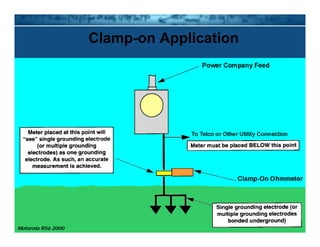

This document discusses grounding and bonding testing procedures. It begins with an overview of the key steps: 1) performing an earth (soil) resistivity test, 2) installing the grounding system, and 3) testing the installed system. It then covers details of soil resistivity testing including how to measure resistivity and factors that affect resistivity. The document reviews components of a grounding system including electrodes, conductors, bars and connection methods. It provides guidance on proper installation and inspection of connections. Finally, it stresses the importance of testing the completed system to ensure it is effective.