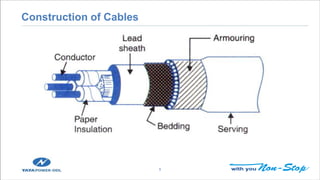

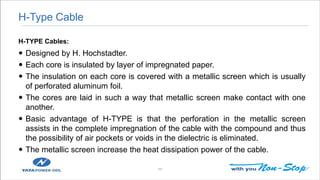

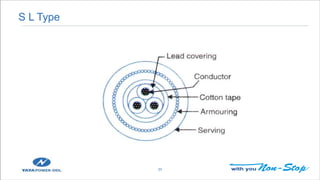

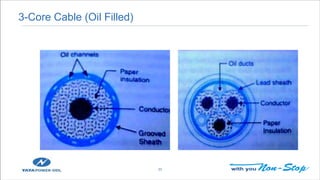

The document discusses underground cables, highlighting their construction, advantages, and disadvantages compared to overhead systems. It covers various types of cables based on voltage levels, insulation materials, and installation methods, as well as issues related to grading and earth faults. Additionally, it compares the costs of underground and overhead transmission and distribution systems, noting that while underground cables may be more expensive, they provide better reliability and aesthetics.