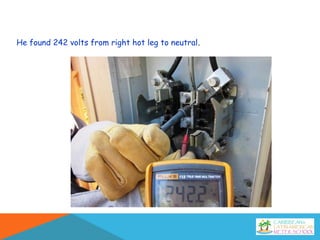

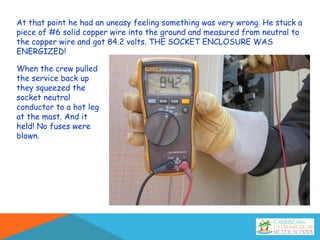

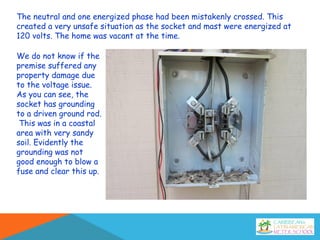

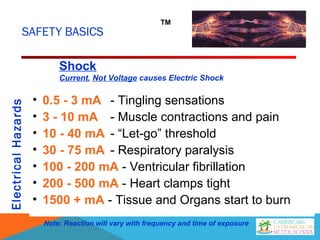

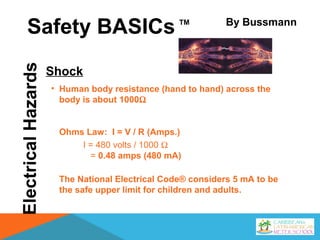

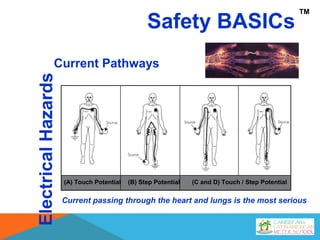

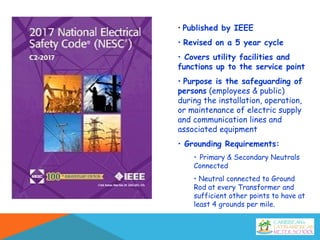

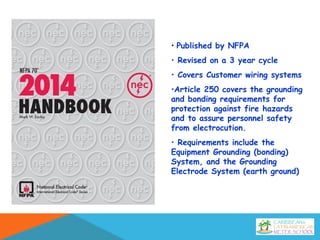

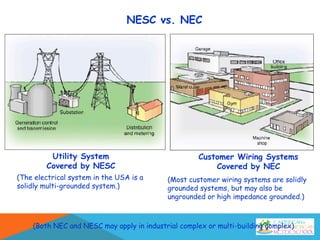

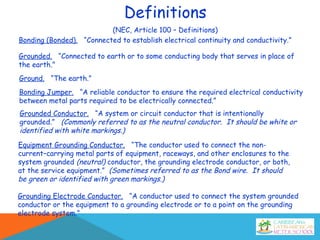

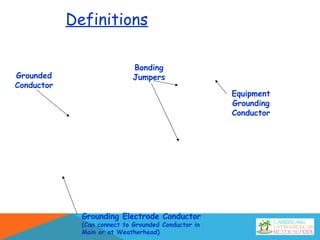

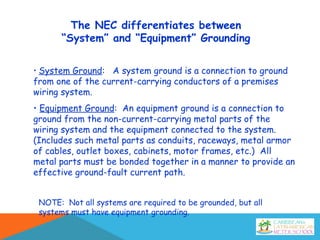

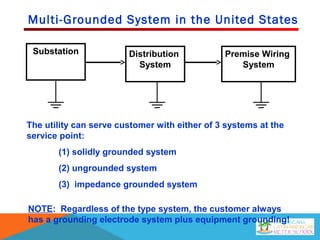

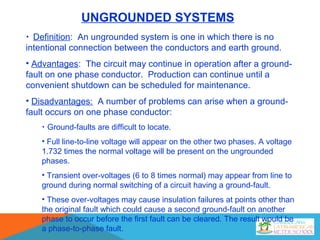

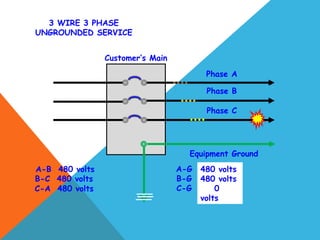

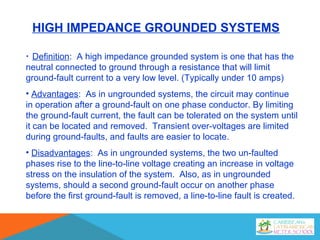

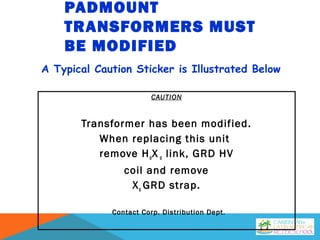

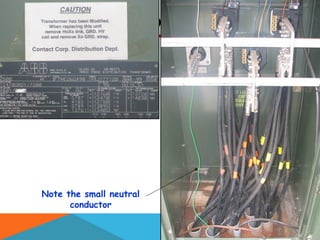

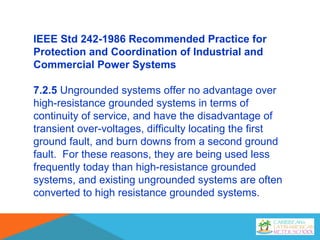

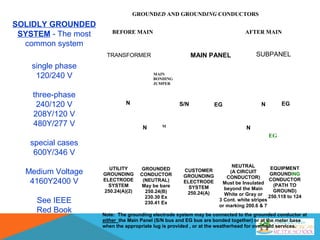

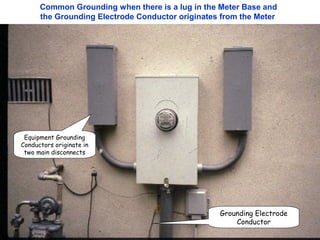

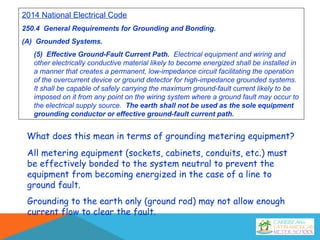

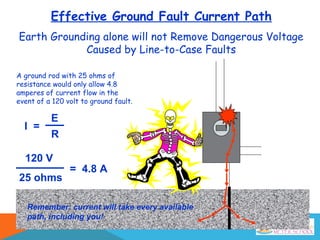

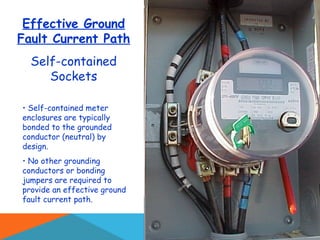

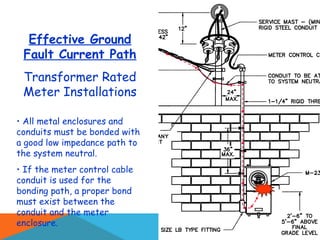

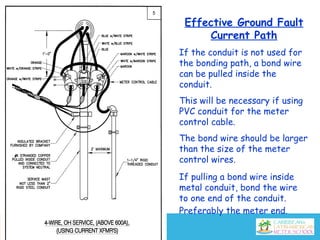

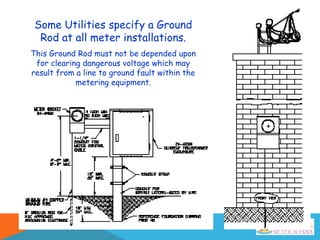

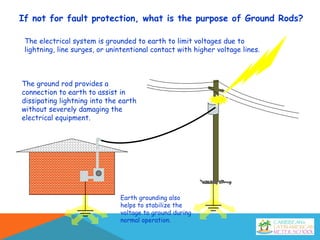

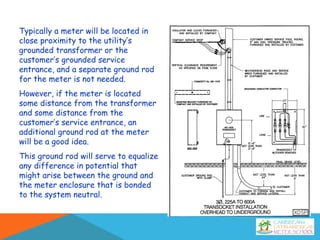

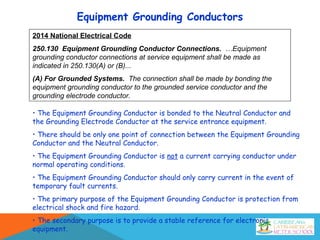

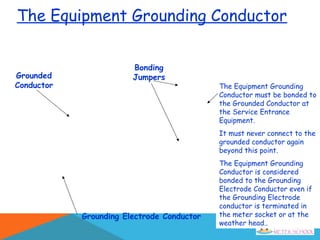

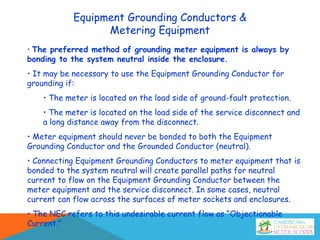

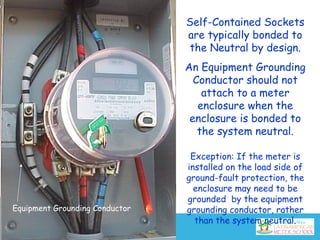

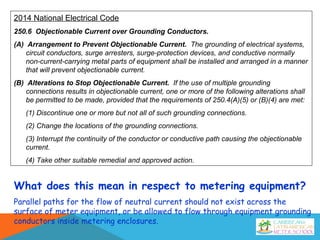

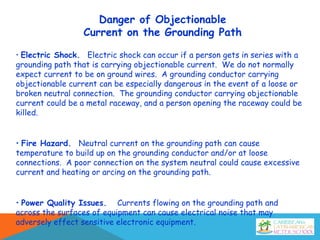

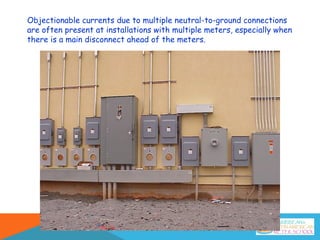

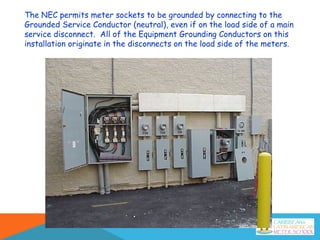

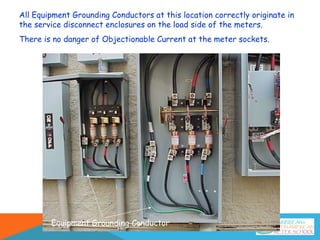

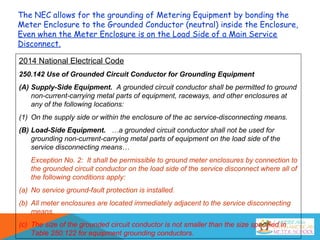

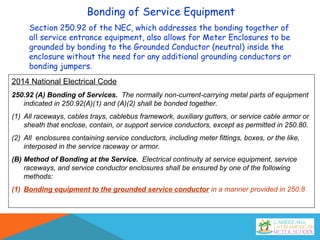

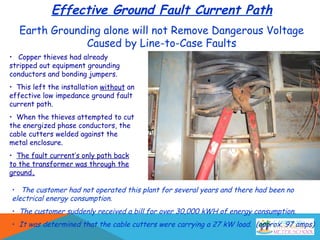

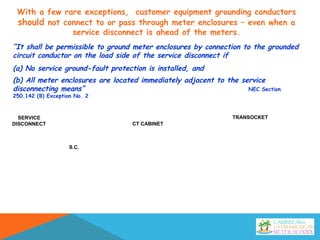

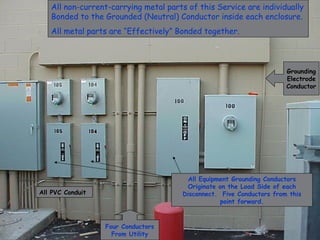

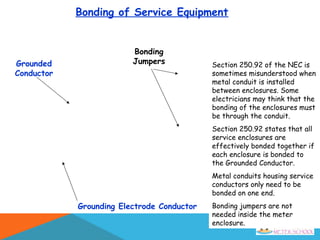

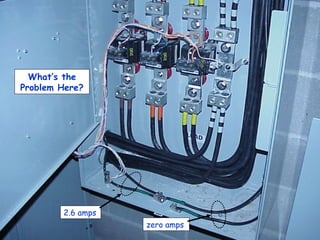

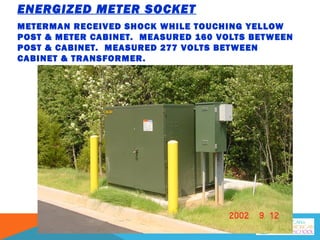

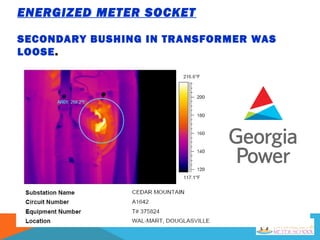

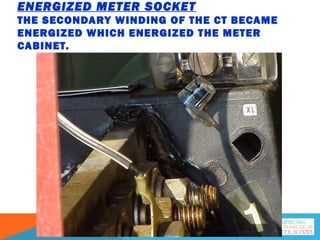

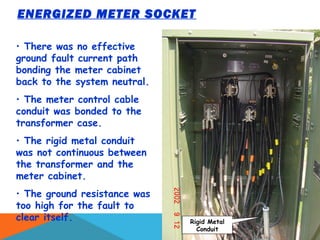

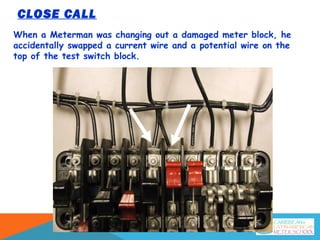

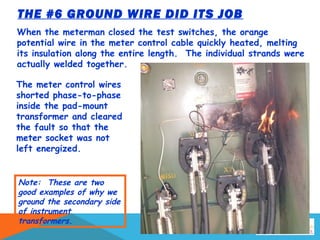

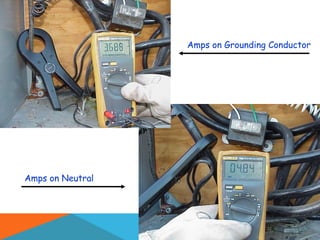

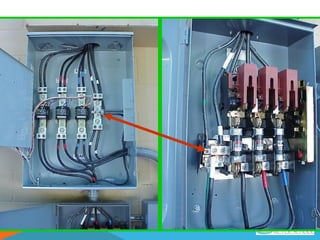

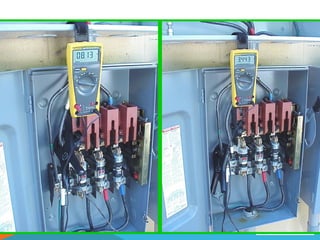

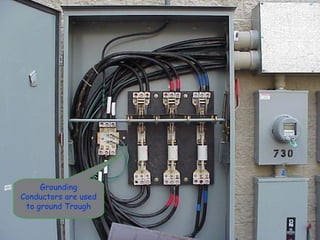

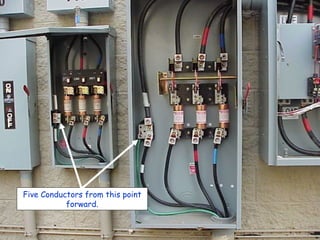

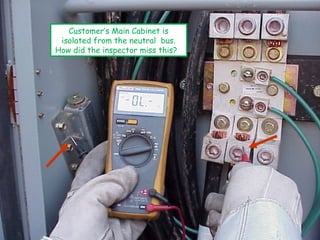

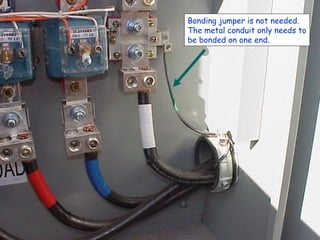

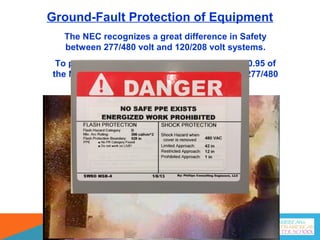

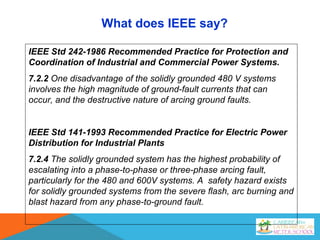

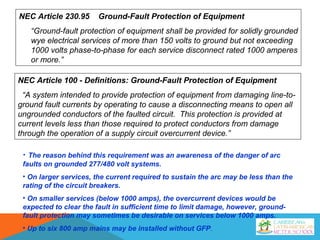

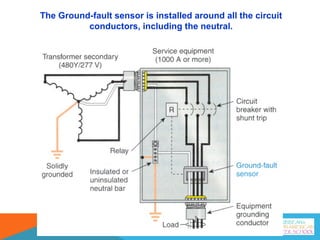

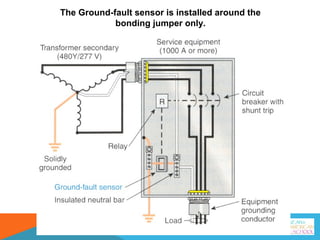

The document discusses grounding and bonding practices in electrical systems, highlighting an incident involving incorrect neutral connections that resulted in dangerous voltage levels. It outlines the importance of proper grounding for safety, operational integrity, and equipment protection, distinguishing between various grounding systems such as solidly grounded, ungrounded, and high impedance systems. Additionally, it details relevant National Electrical Code (NEC) requirements and safety guidelines to prevent electrical hazards and ensure effective grounding practices.