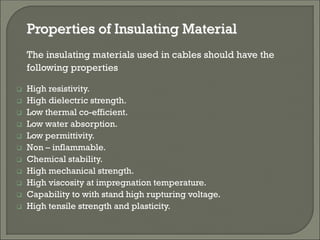

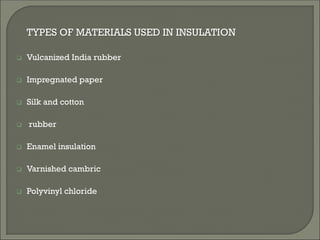

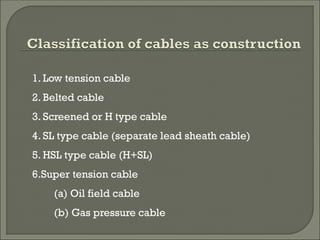

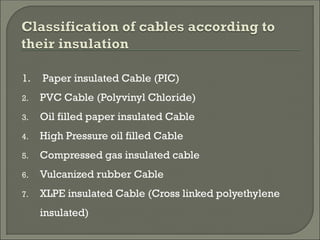

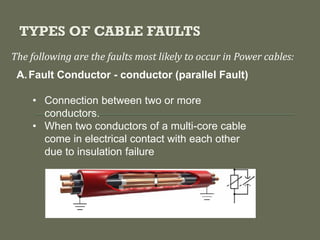

This document discusses various aspects of oil impregnated paper cables and extruded cables, including their construction, classification, properties of insulating materials, and common faults. It highlights the types of materials used in insulation, fault occurrences, and contrasts the advantages and disadvantages of paper insulation versus polymer (XLPE) cables. Additionally, it mentions monitoring methods for cable conditions and stresses the importance of selecting suitable cables based on operational requirements.

![ Paper or paper propylene

laminated (PPL) insulated with

individual metal sheaths and

impregnated with low pressure oil

It is estimated that about 83% of HV

cables in existing systems are paper

insulated [1].

At higher voltages they present

operational problems due to high

dielectric losses and presence of

voids.](https://image.slidesharecdn.com/power-cables-160211193139/85/Power-cables-16-320.jpg)

![ Paper insulation is still common, especially for land UG cables.

However, there is an increasing application of polymer cables

(XLPE),especially for in DC and submarine installations.

In polymer insulation the insulating XLPE compounds must act as

thermoplastic materials, be immune to thermal degradation and

must not be prone to defects such as voids ,contaminants [1].](https://image.slidesharecdn.com/power-cables-160211193139/85/Power-cables-18-320.jpg)

![ XLPE cables constitute about 2 - 5% of installed HV cable

capacity in the 115-161 kV range, and make up about 50 -

70% of new cable installations in the HV range(220KV and

more) [1].](https://image.slidesharecdn.com/power-cables-160211193139/85/Power-cables-19-320.jpg)