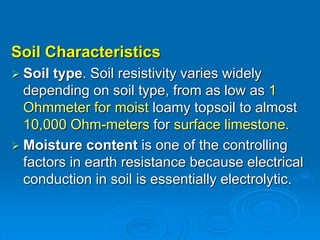

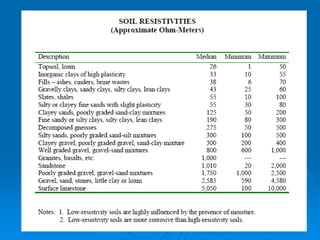

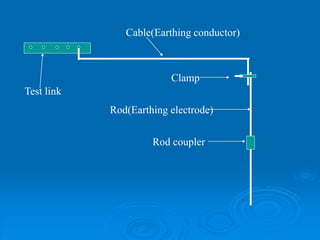

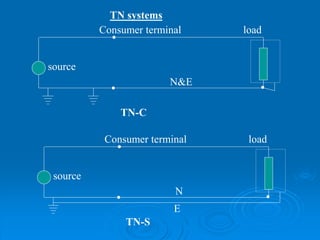

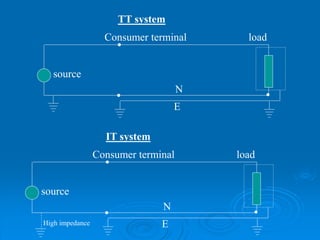

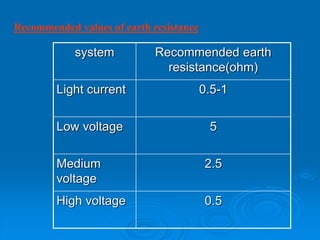

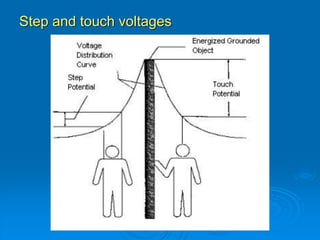

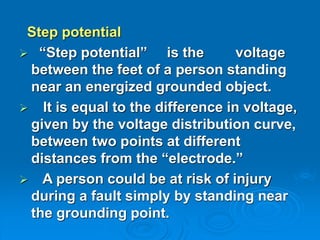

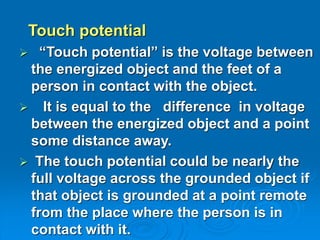

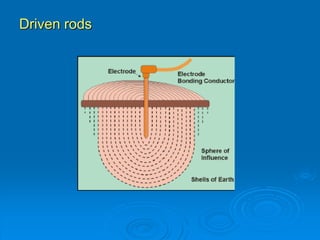

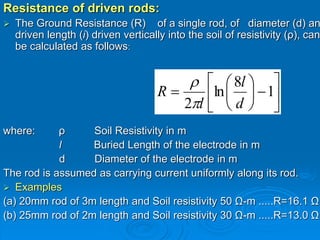

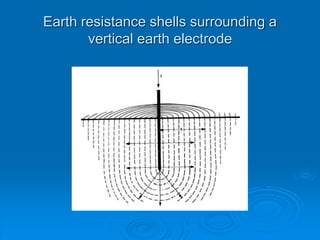

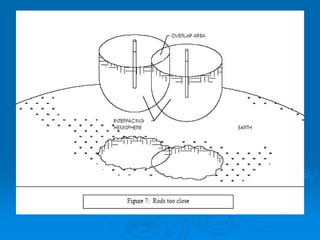

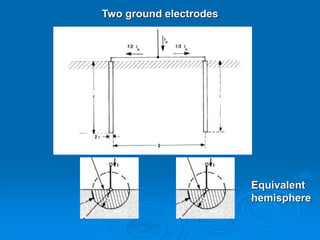

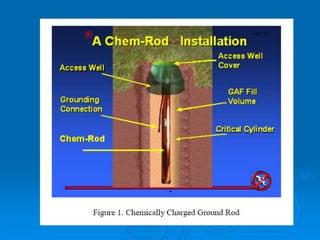

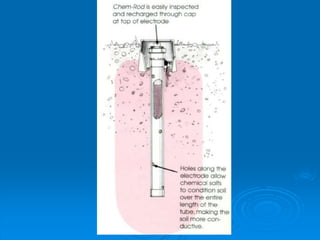

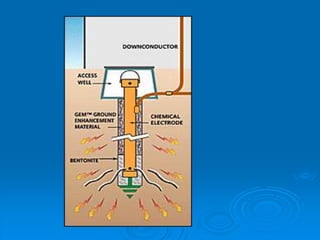

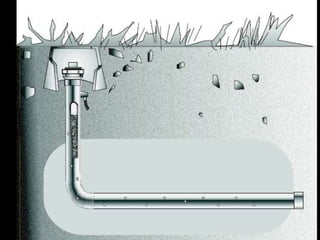

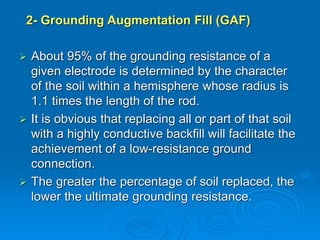

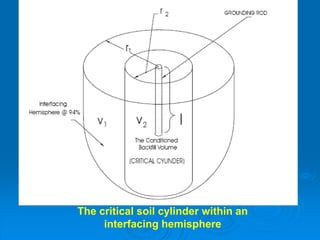

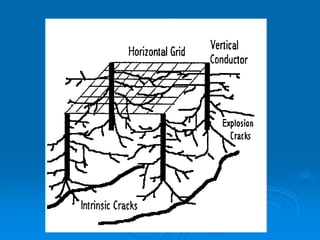

The document discusses grounding systems and their objectives which are to provide safety, ensure correct operation of equipment, prevent damage, dissipate lightning, stabilize voltage, and divert stray RF energy. It describes the three main types of grounding as equipment, system, and lightning/surge grounding. Various grounding components and methods are defined including earth electrodes, earthing conductors, earthing grids, soil characteristics, recommended earth resistance values, and substation earthing systems. New methods to decrease ground resistance such as chemical rods, grounding augmentation fill, and cracks filled with low resistivity materials are also summarized.