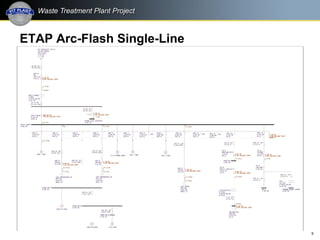

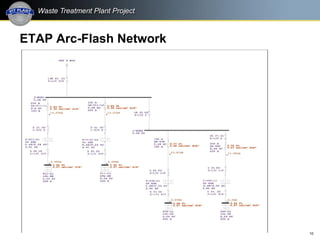

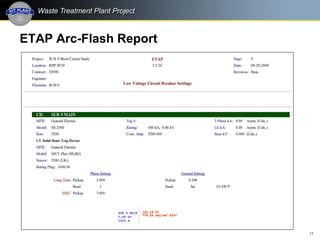

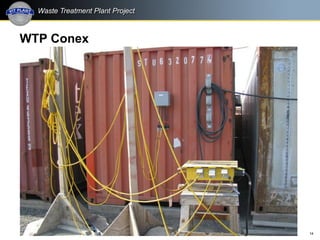

The document outlines lessons learned from electrical construction issues at the Waste Treatment Plant project. It discusses implementing enhanced supplier inspections and NEC code compliance inspections for temporary power installations. It also covers improving electrical design compliance through code training, procuring medium voltage equipment and training, and enhancing lockout/tagout procedures to meet operational safety standards. The overall goal is to apply these lessons to improve electrical safety and performance at the Waste Treatment Plant.