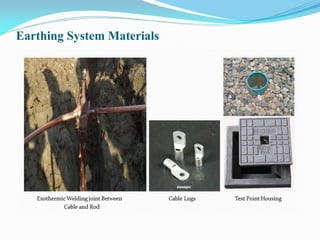

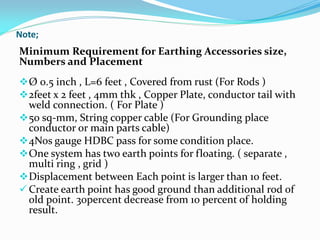

This document provides guidelines for properly installing an earthing system. It describes the working process which includes 1) checking materials and tools, 2) excavating for cable installation, 3) fitting earth rods and connecting them with cables using appropriate joining methods, 4) checking connections and resistance values, and 5) backfilling. Key points emphasized are using the correct accessories sizes, placing earth points at least 10 feet apart, and creating new points if resistance is more than 10% of requirements. Following the outlined process helps ensure a high quality, code-compliant earthing system installation.