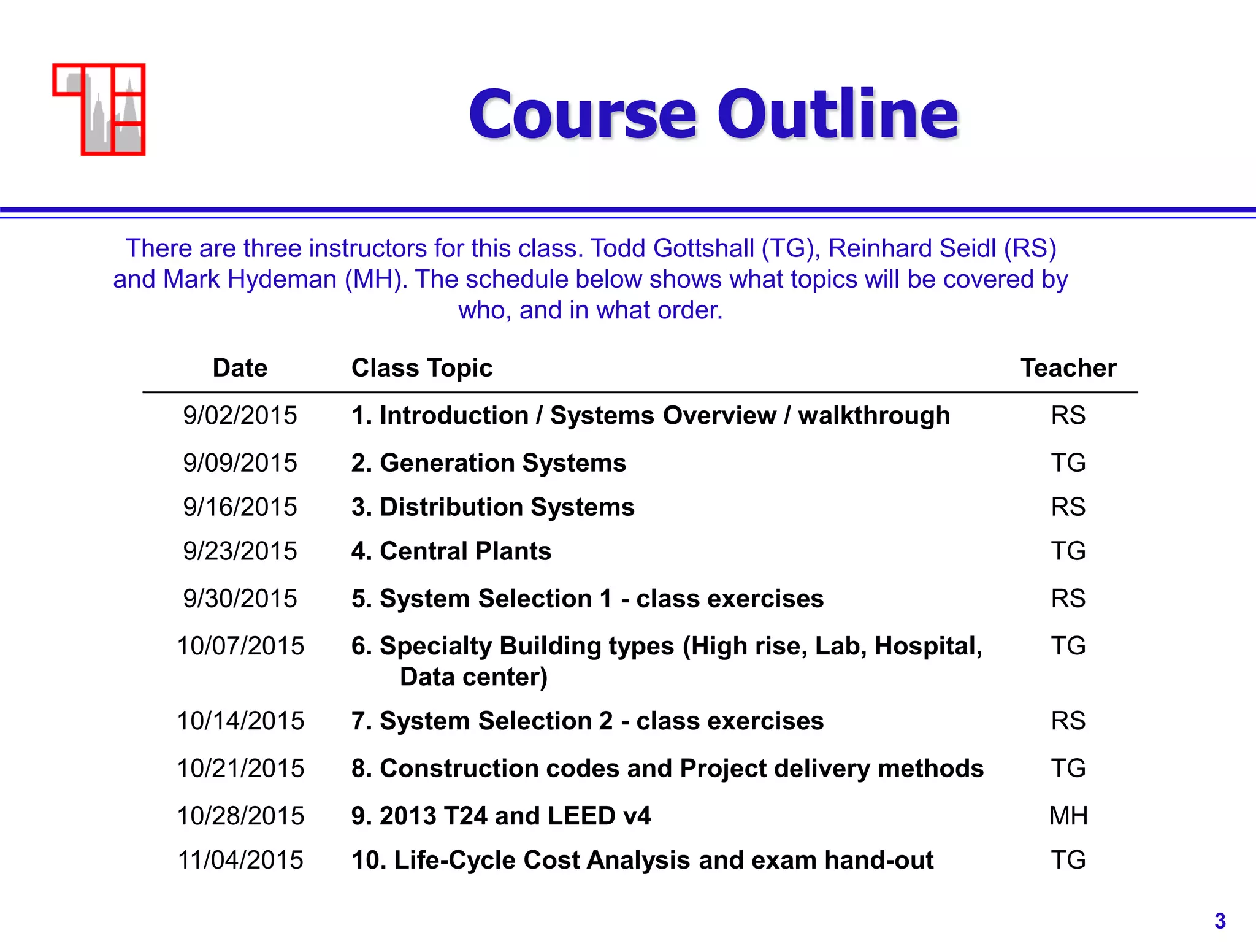

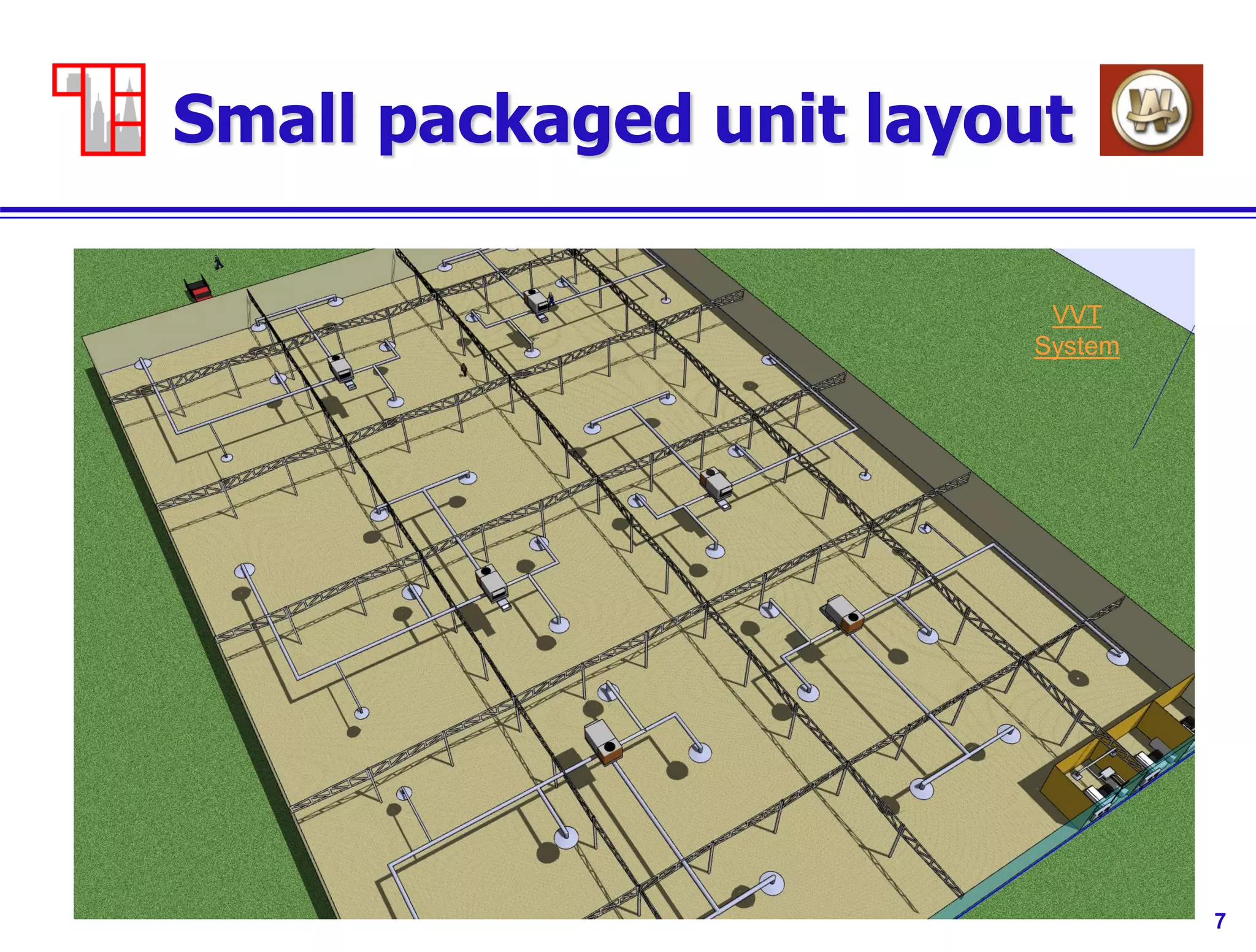

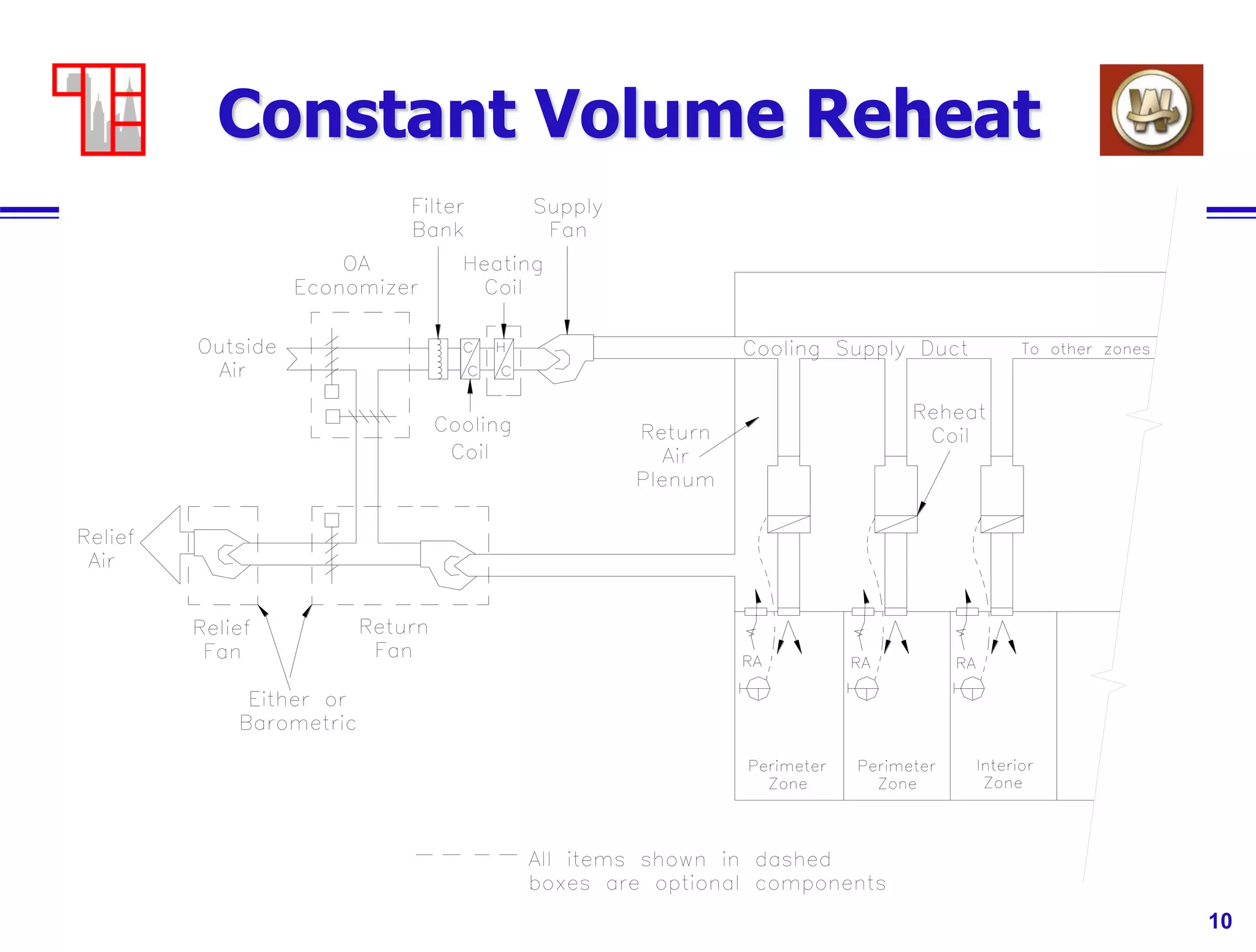

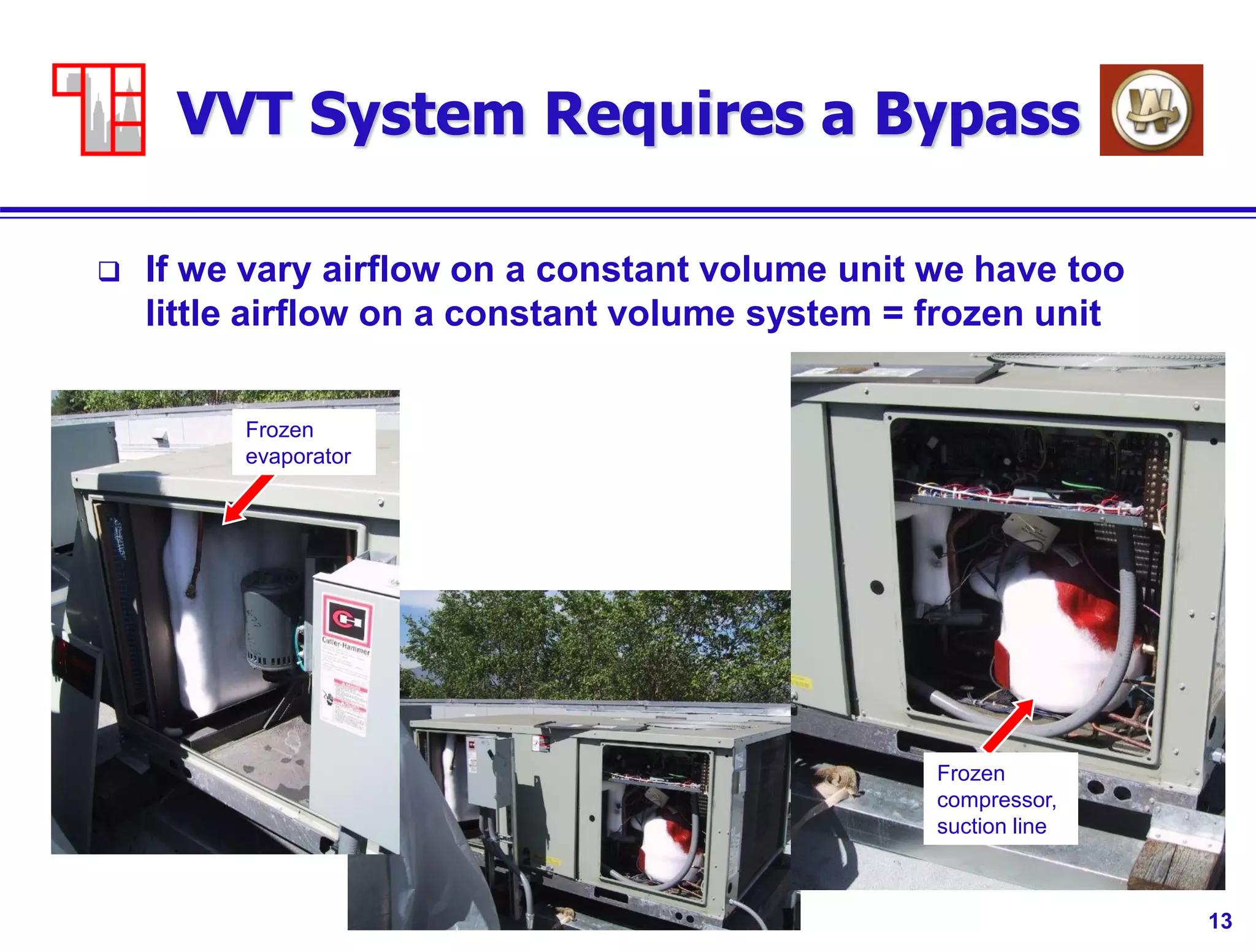

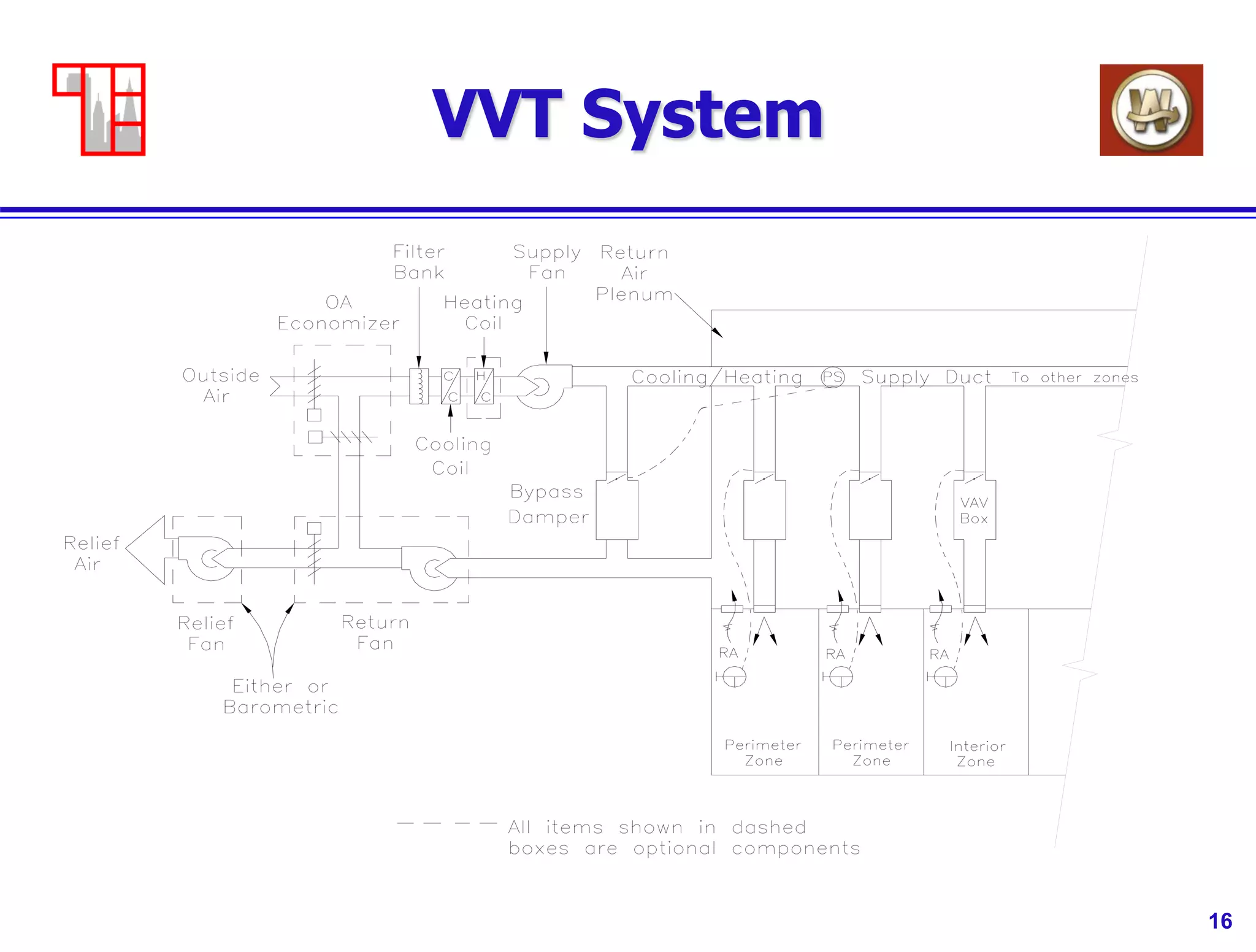

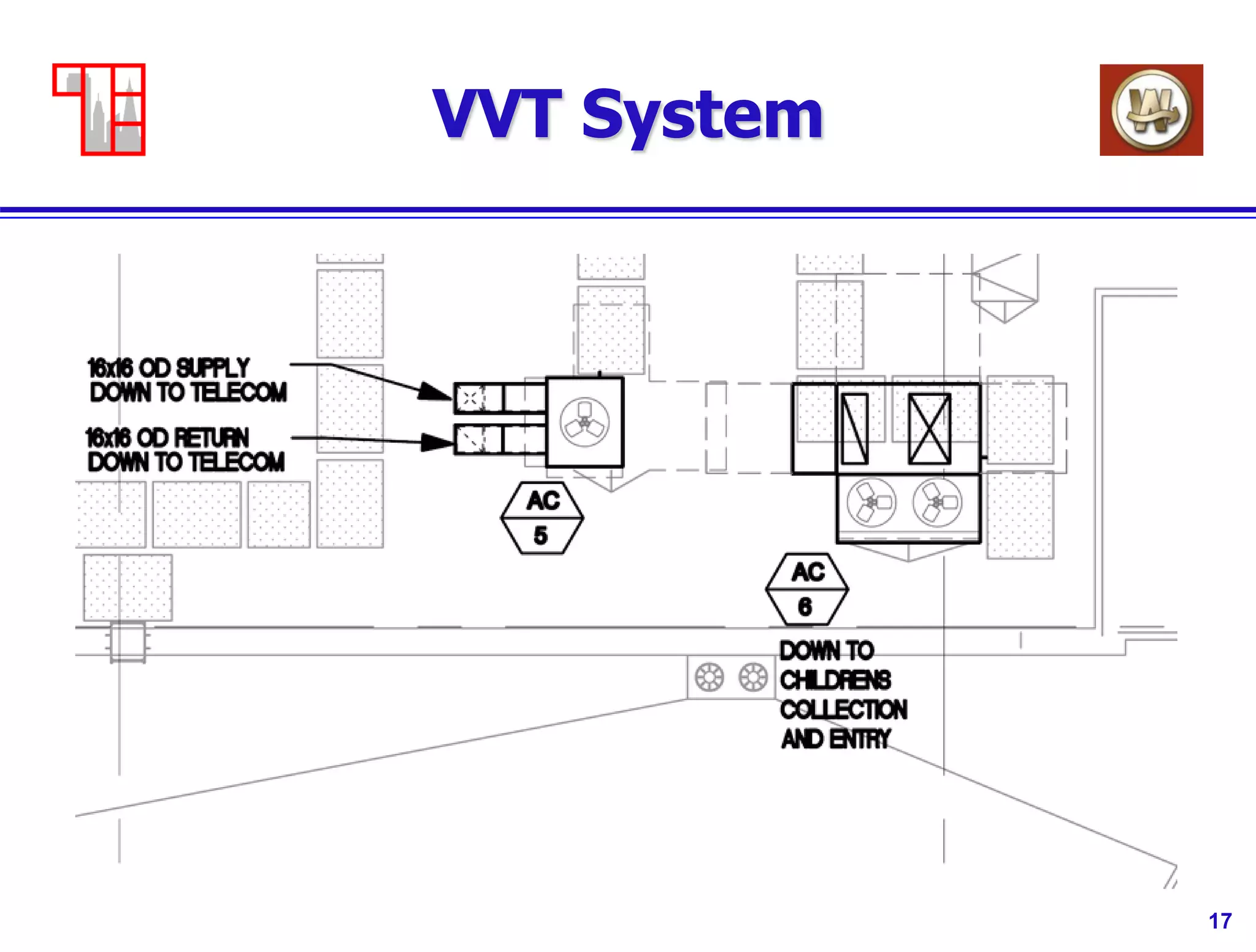

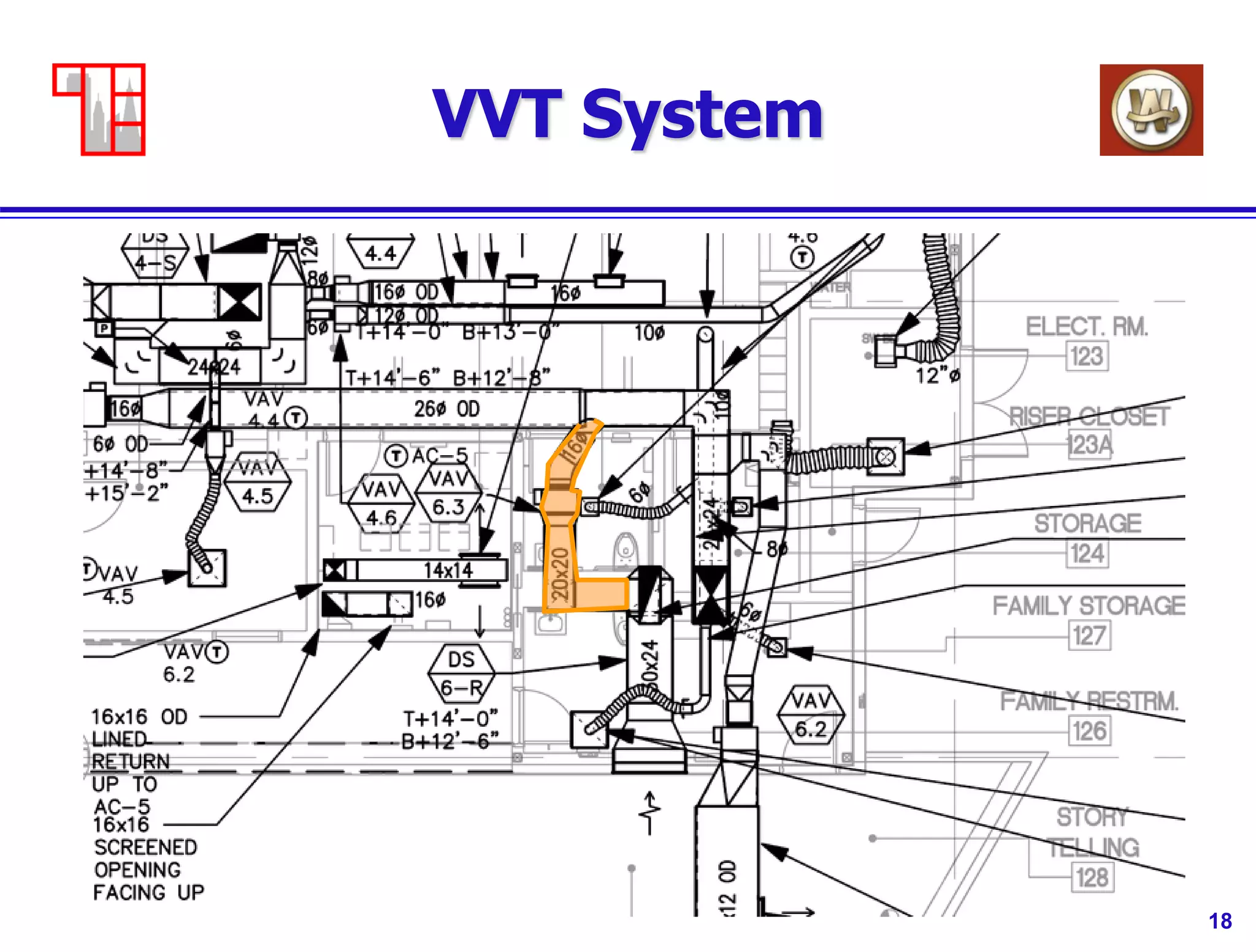

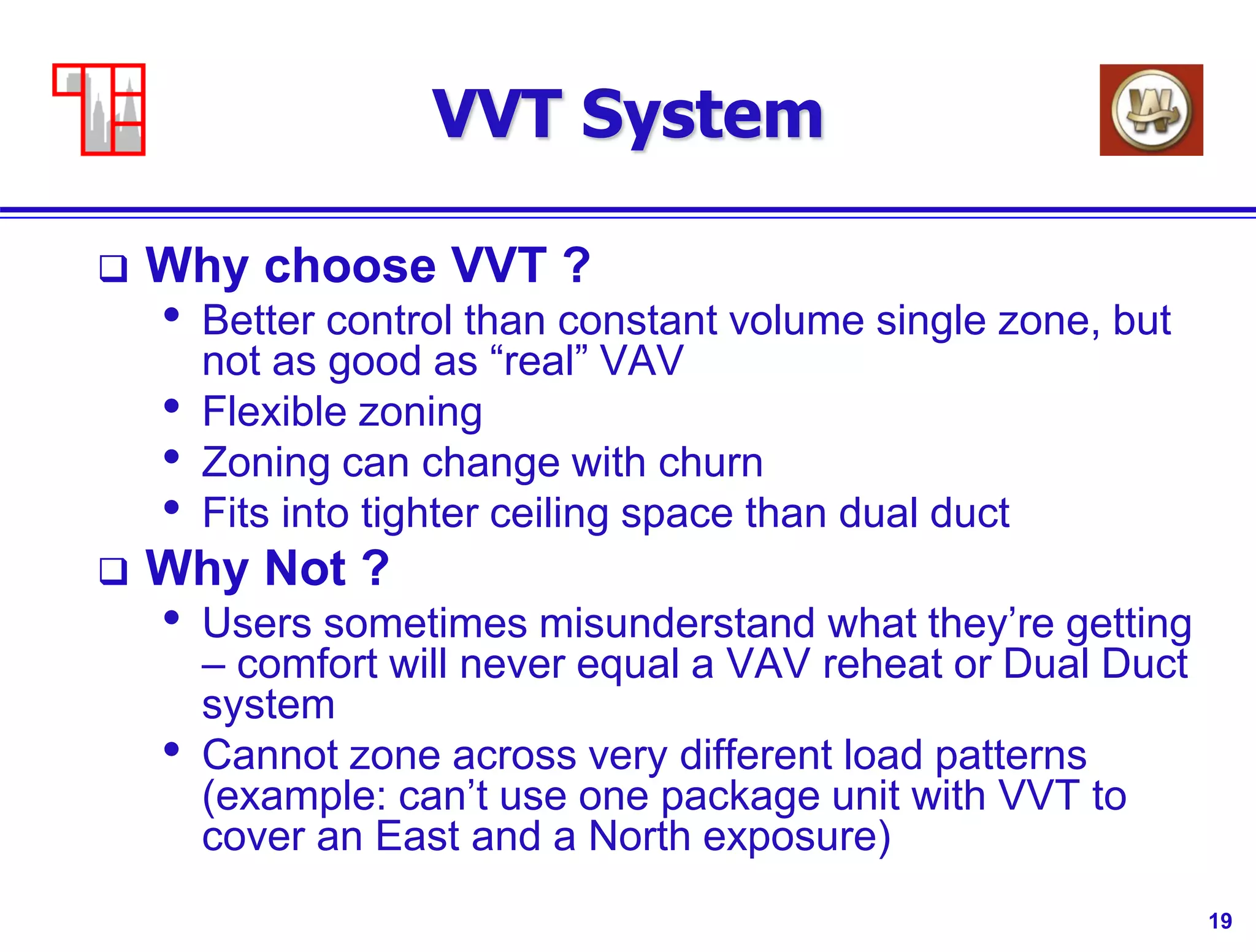

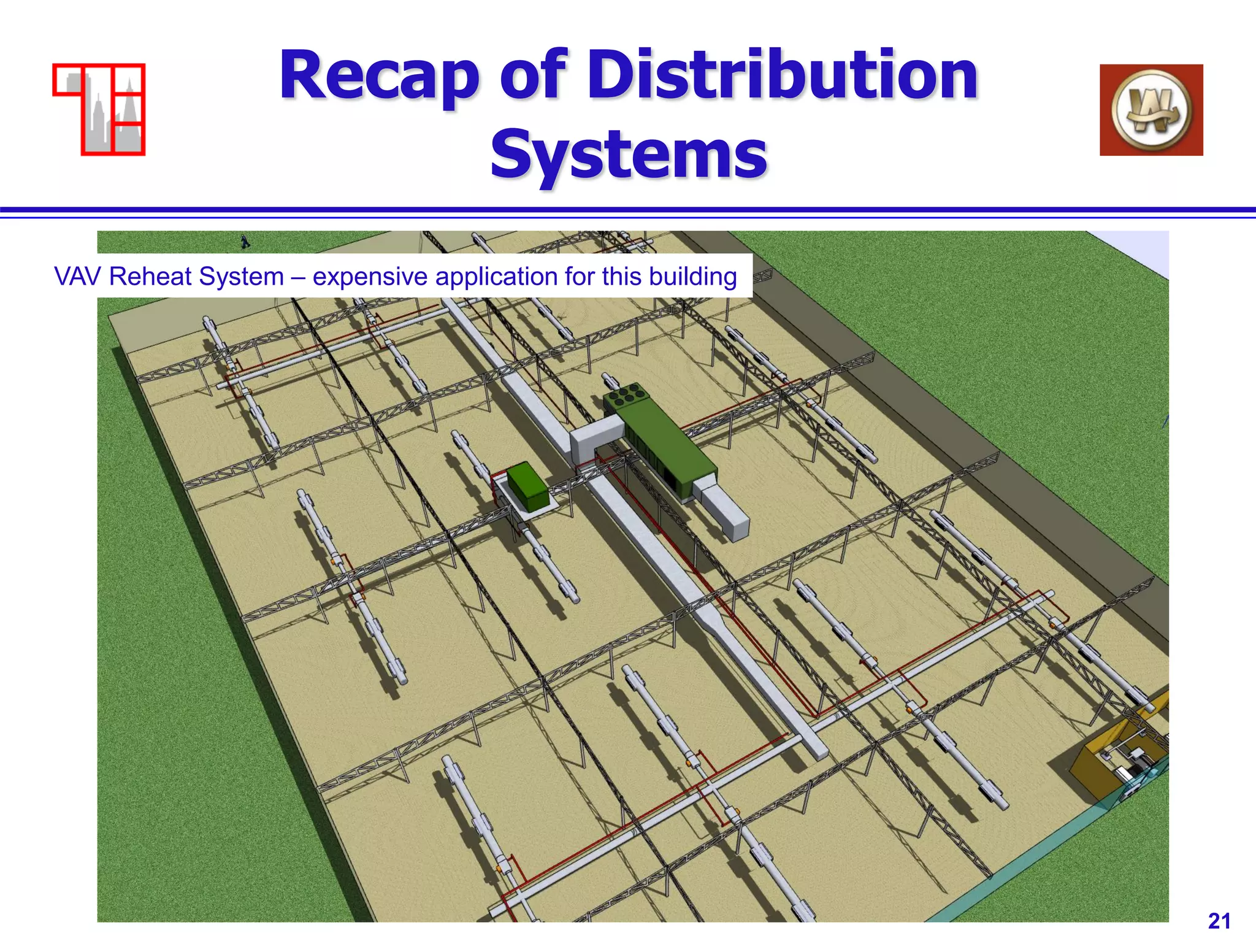

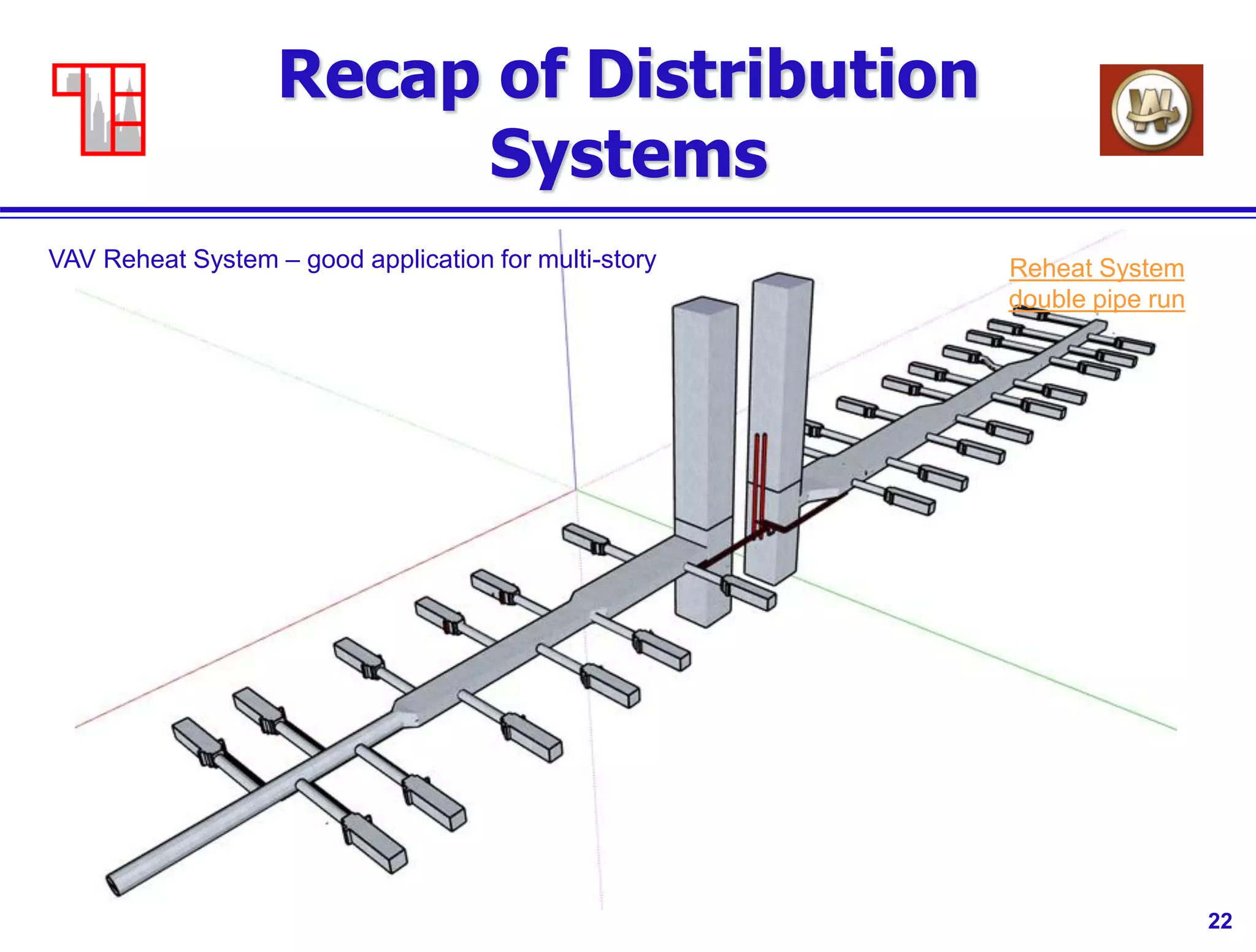

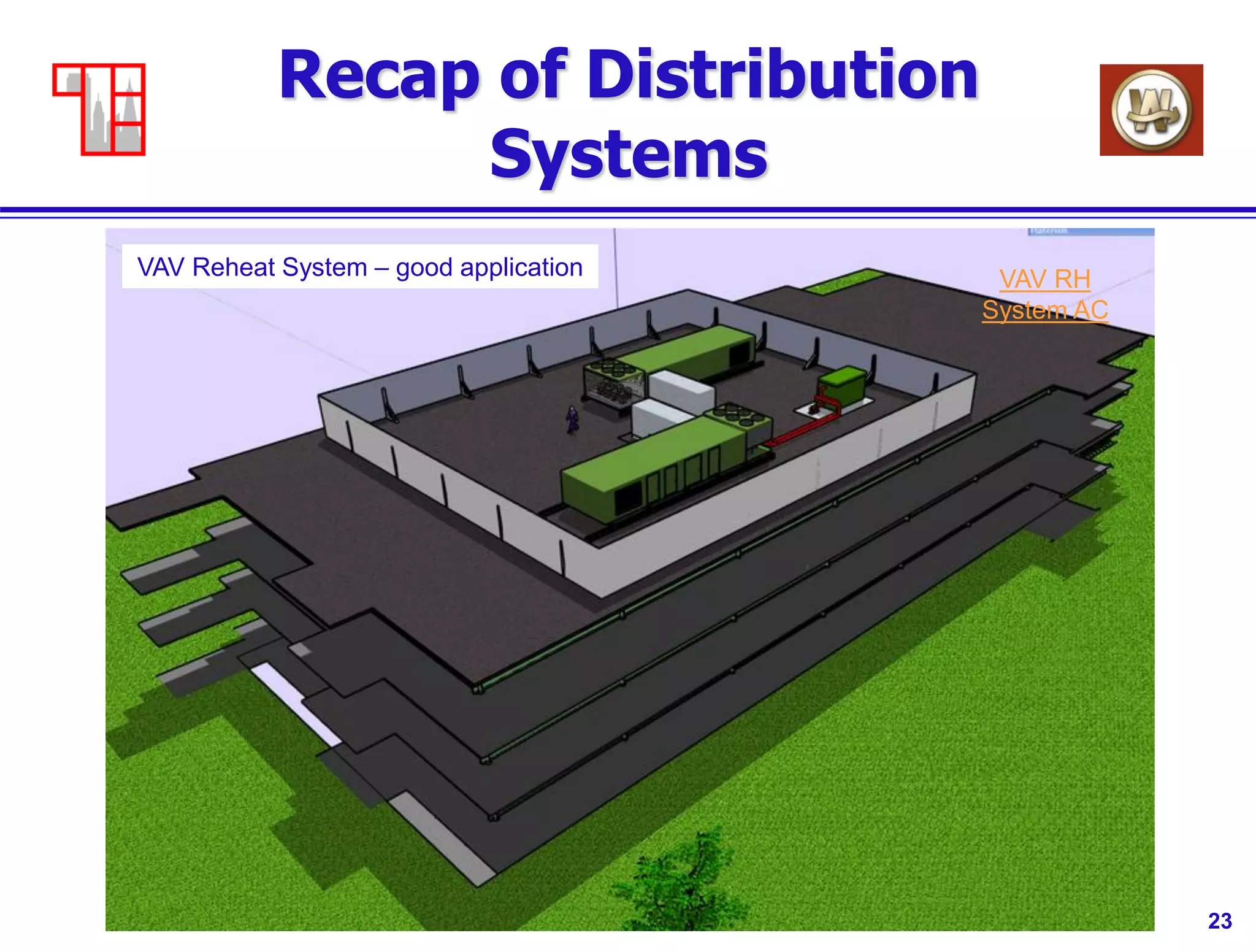

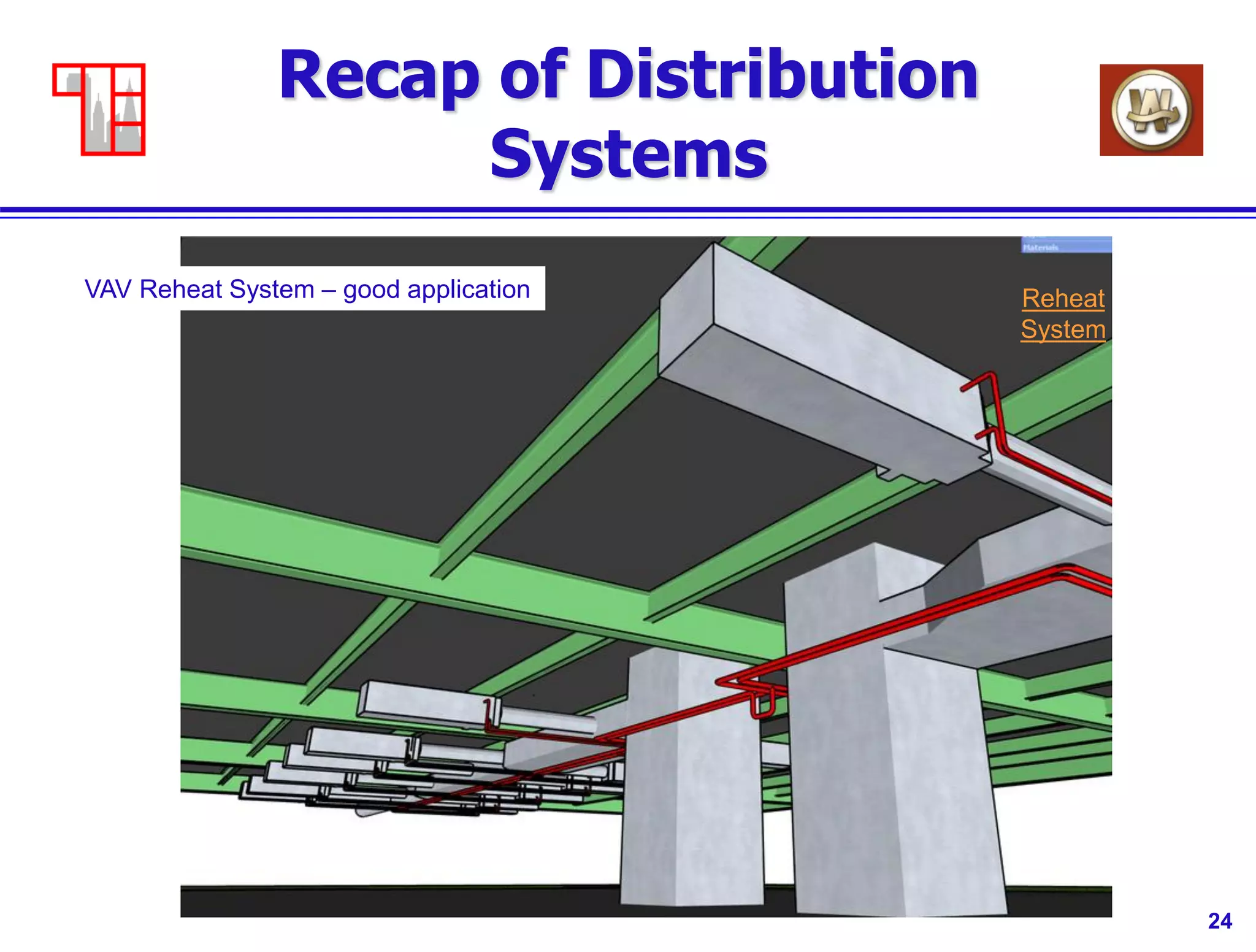

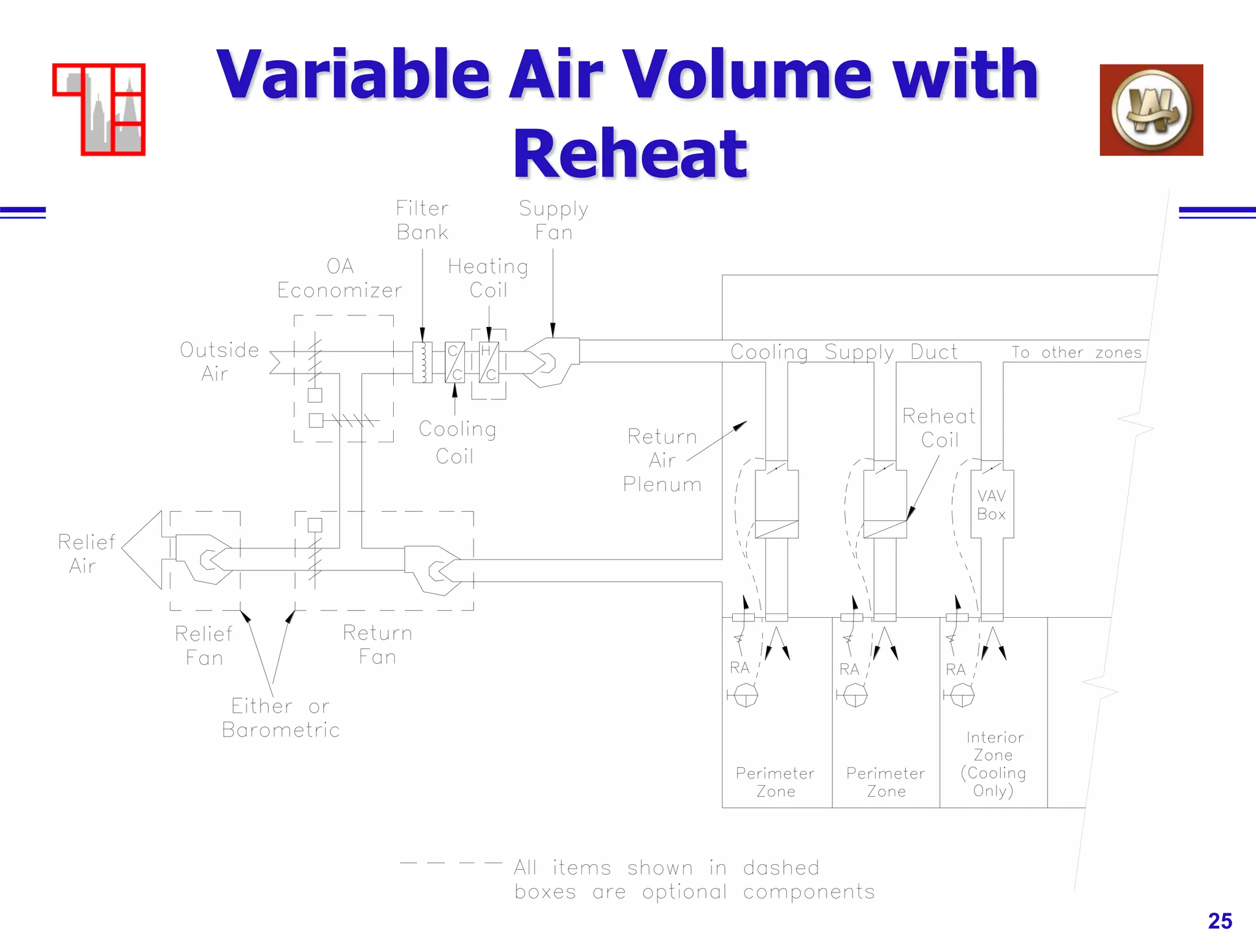

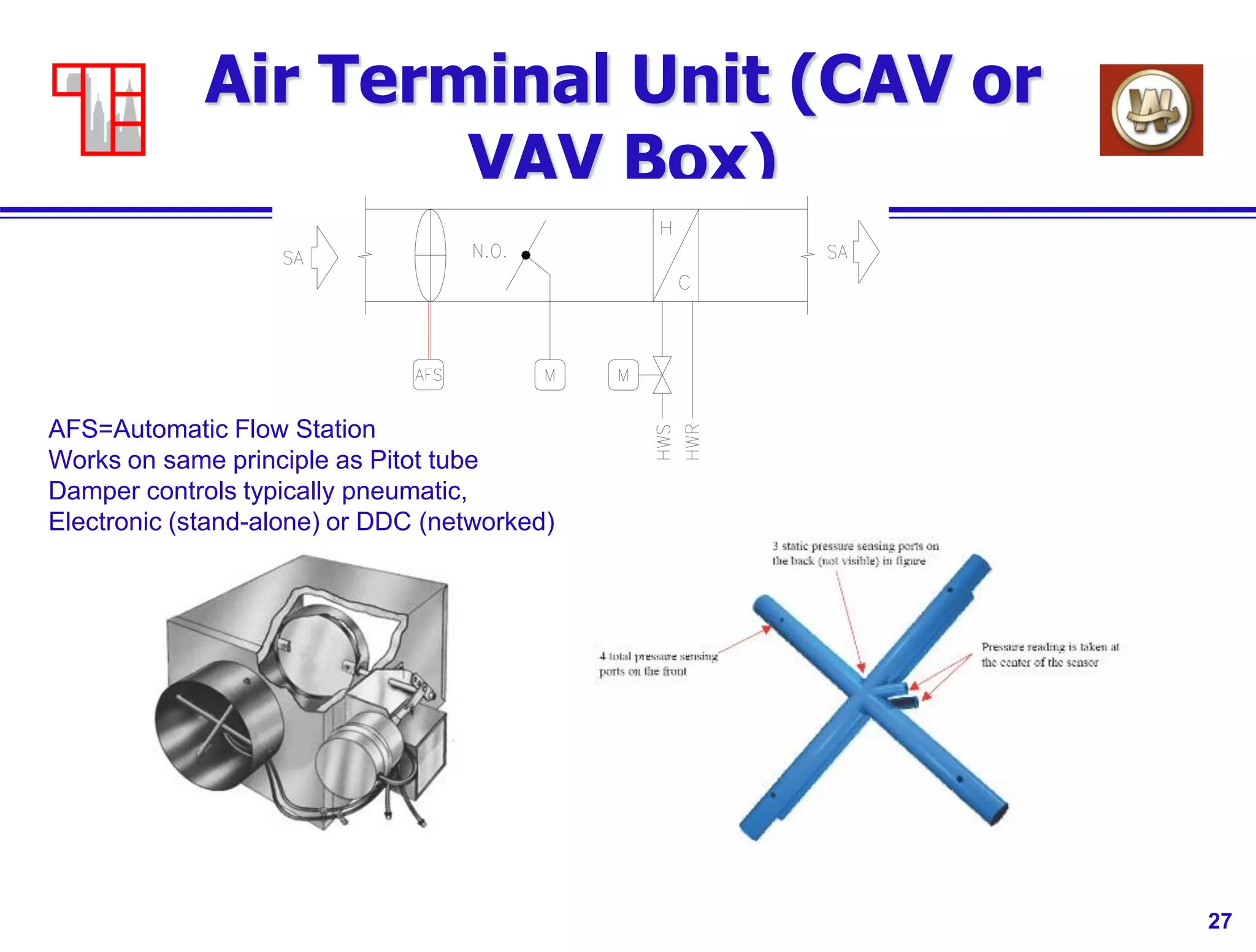

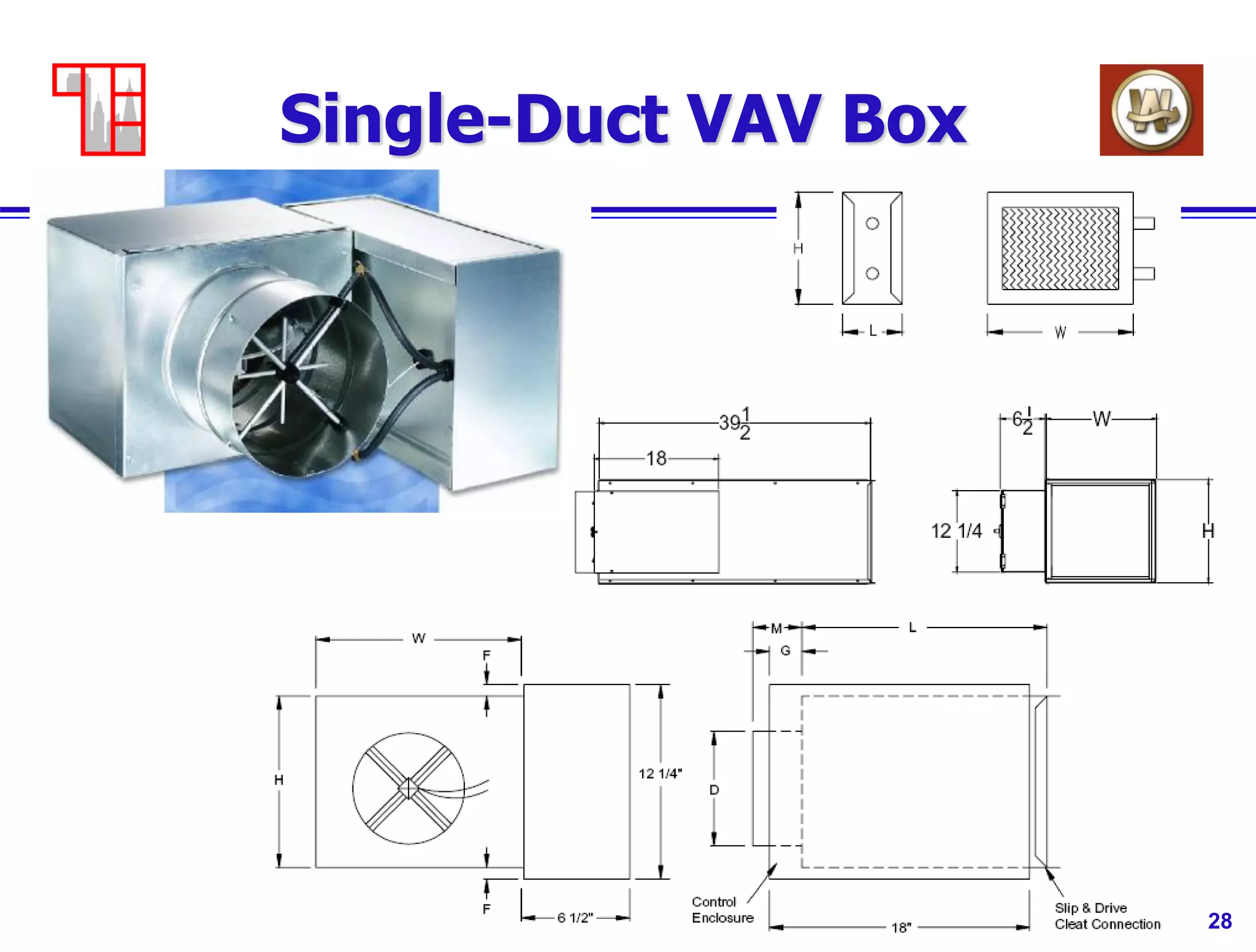

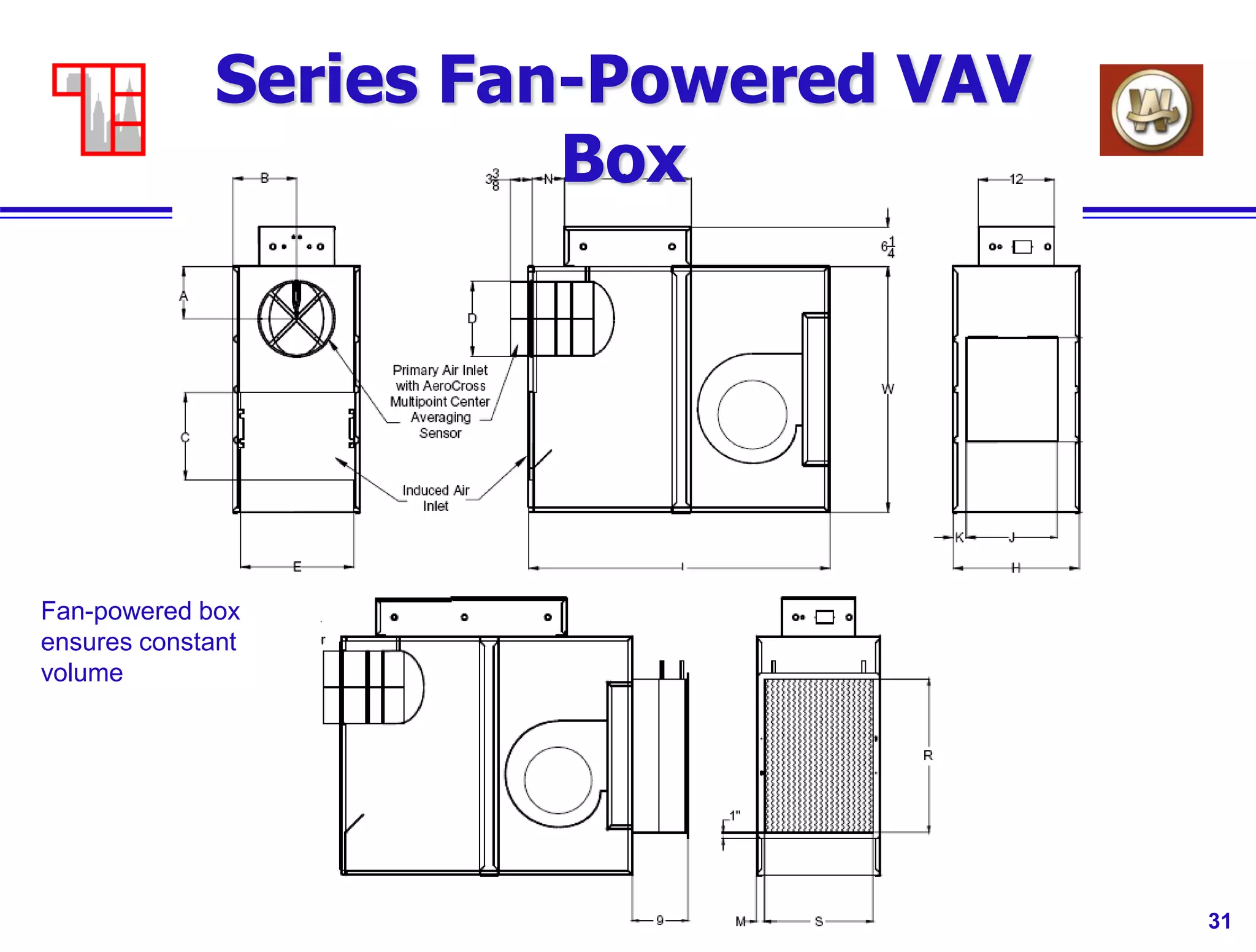

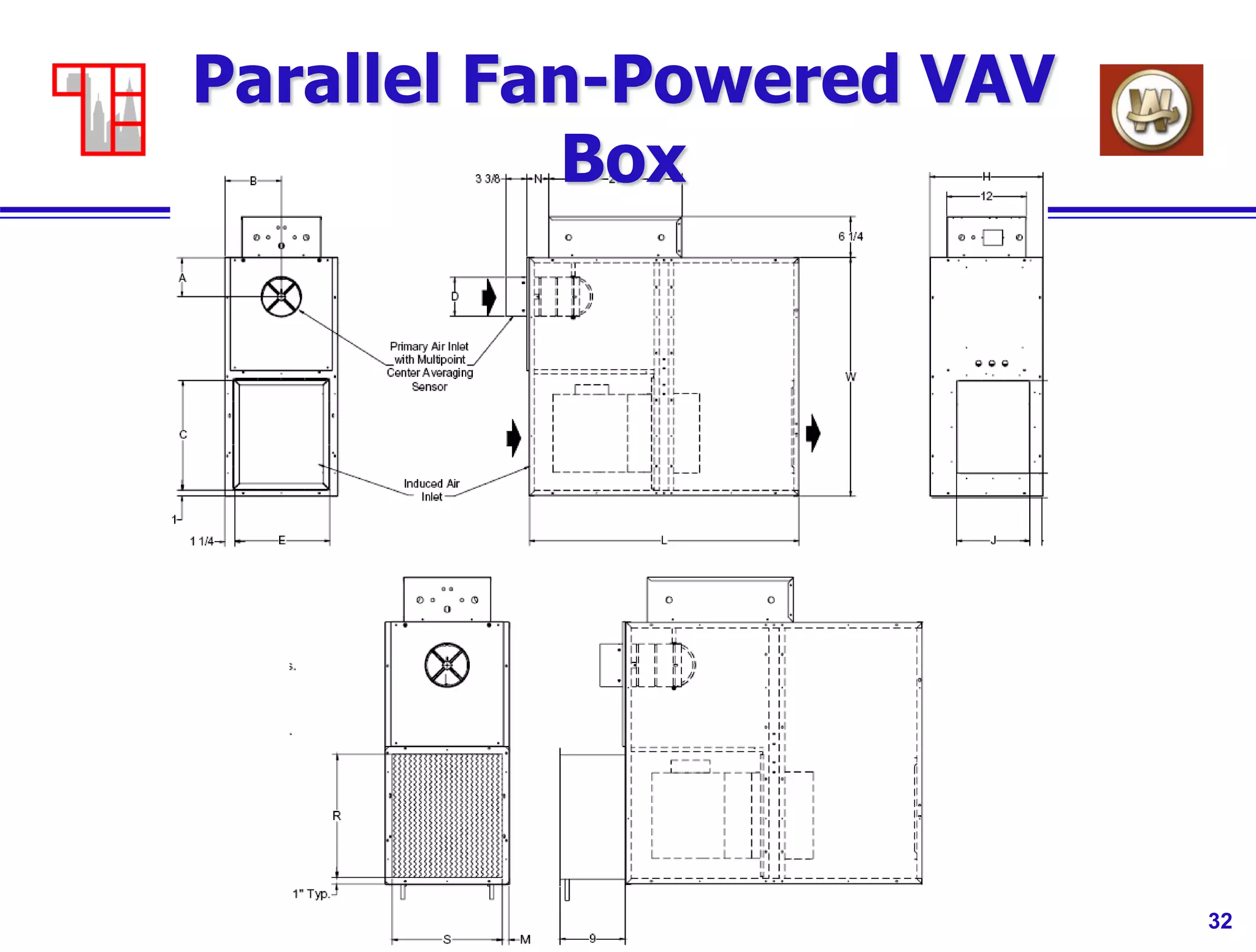

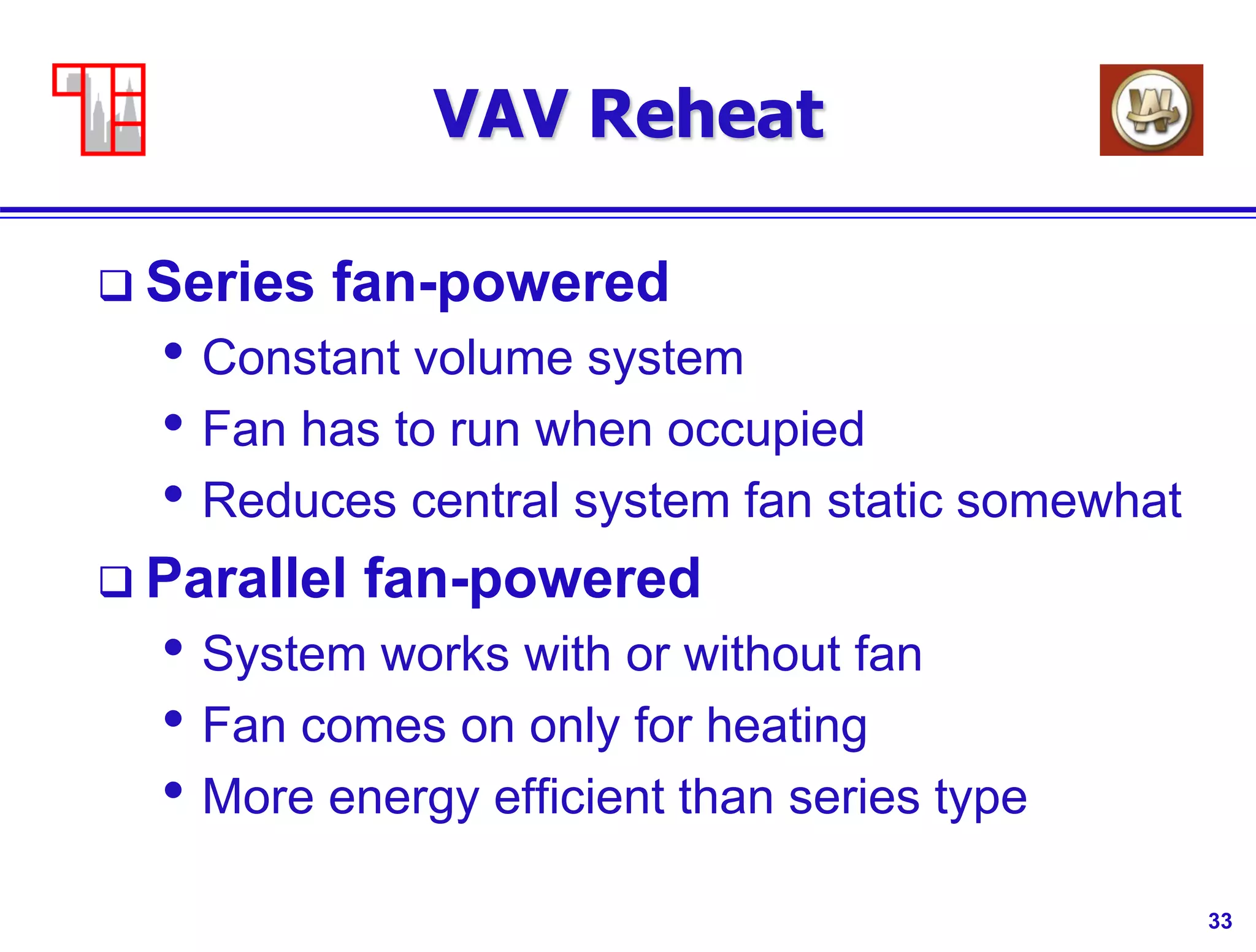

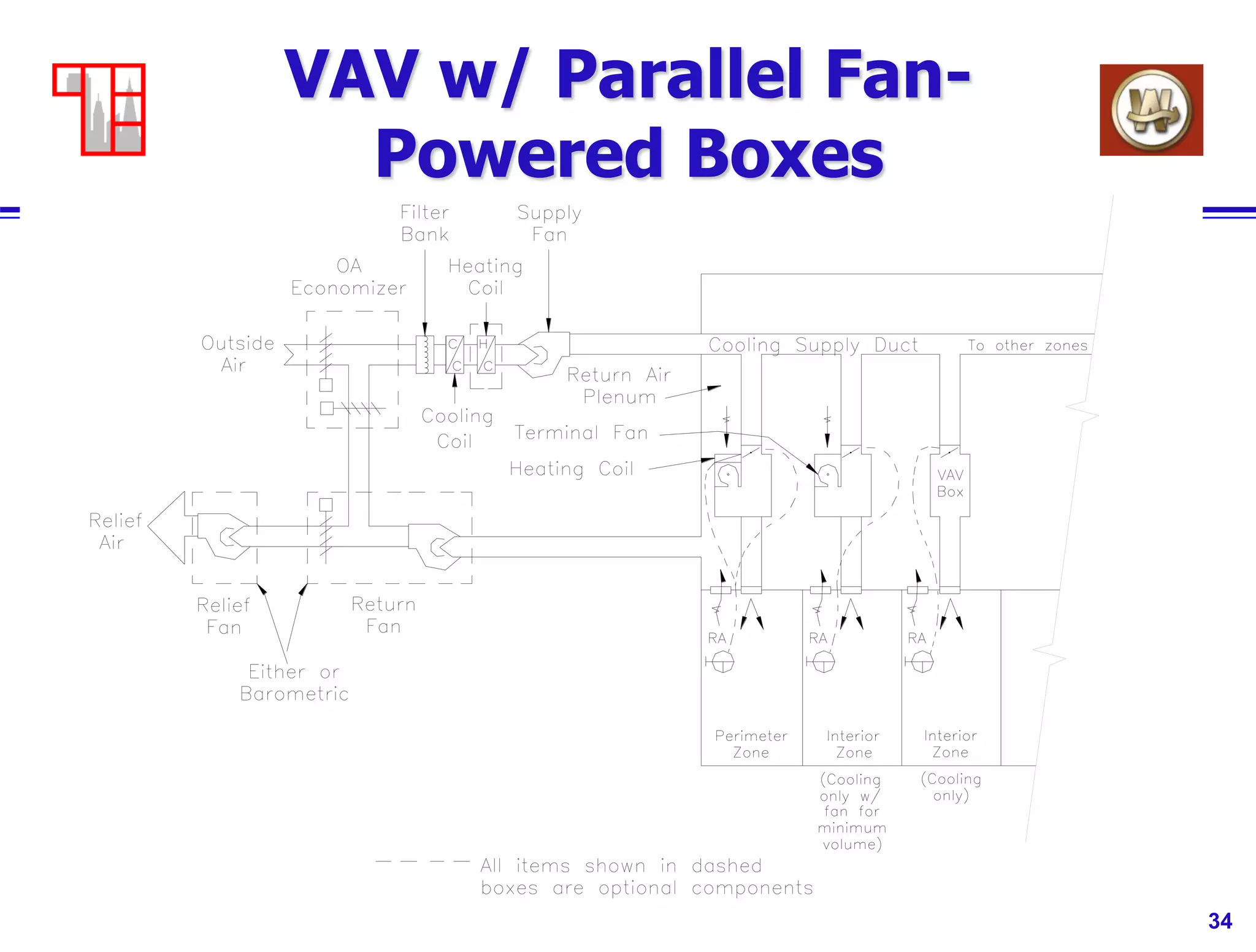

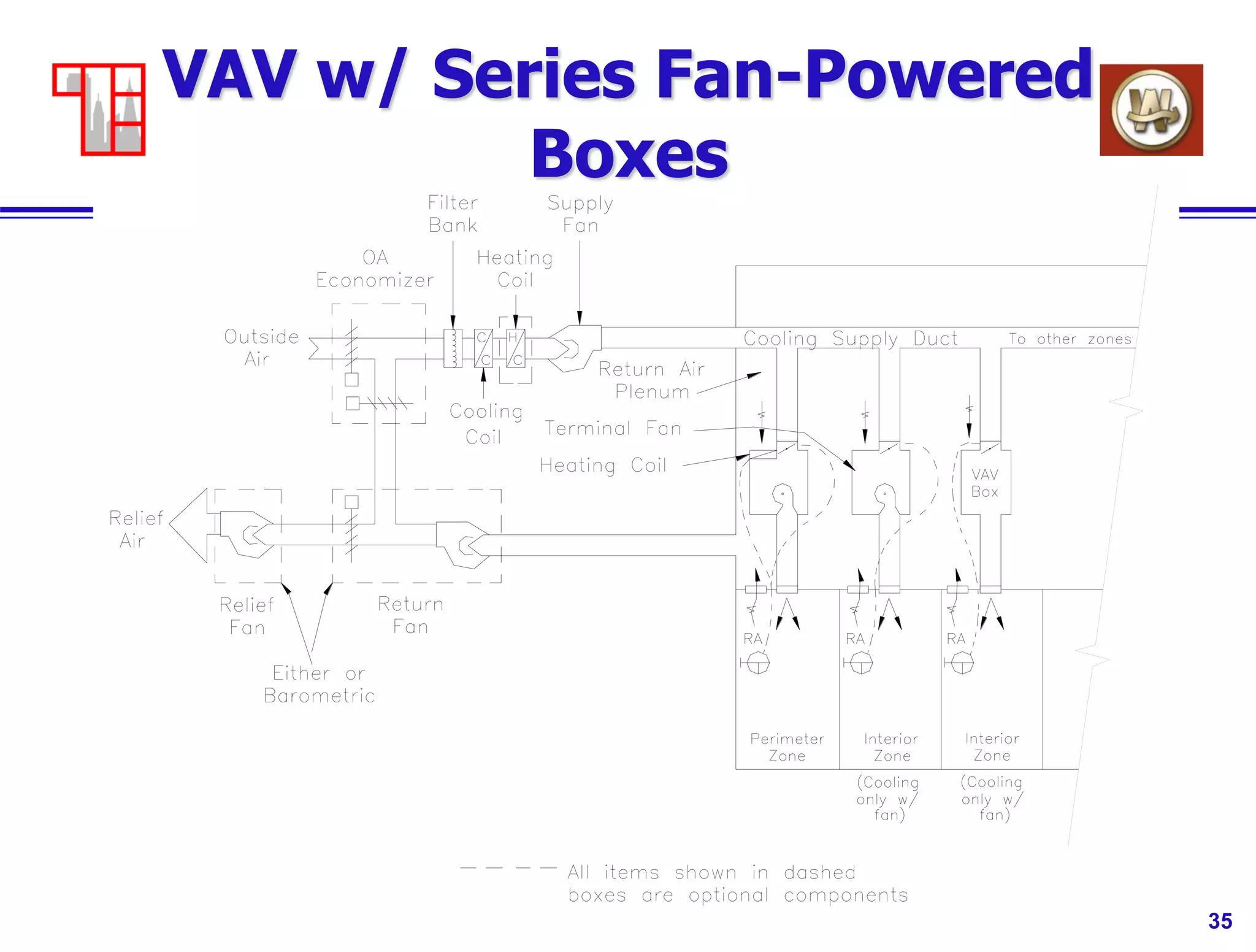

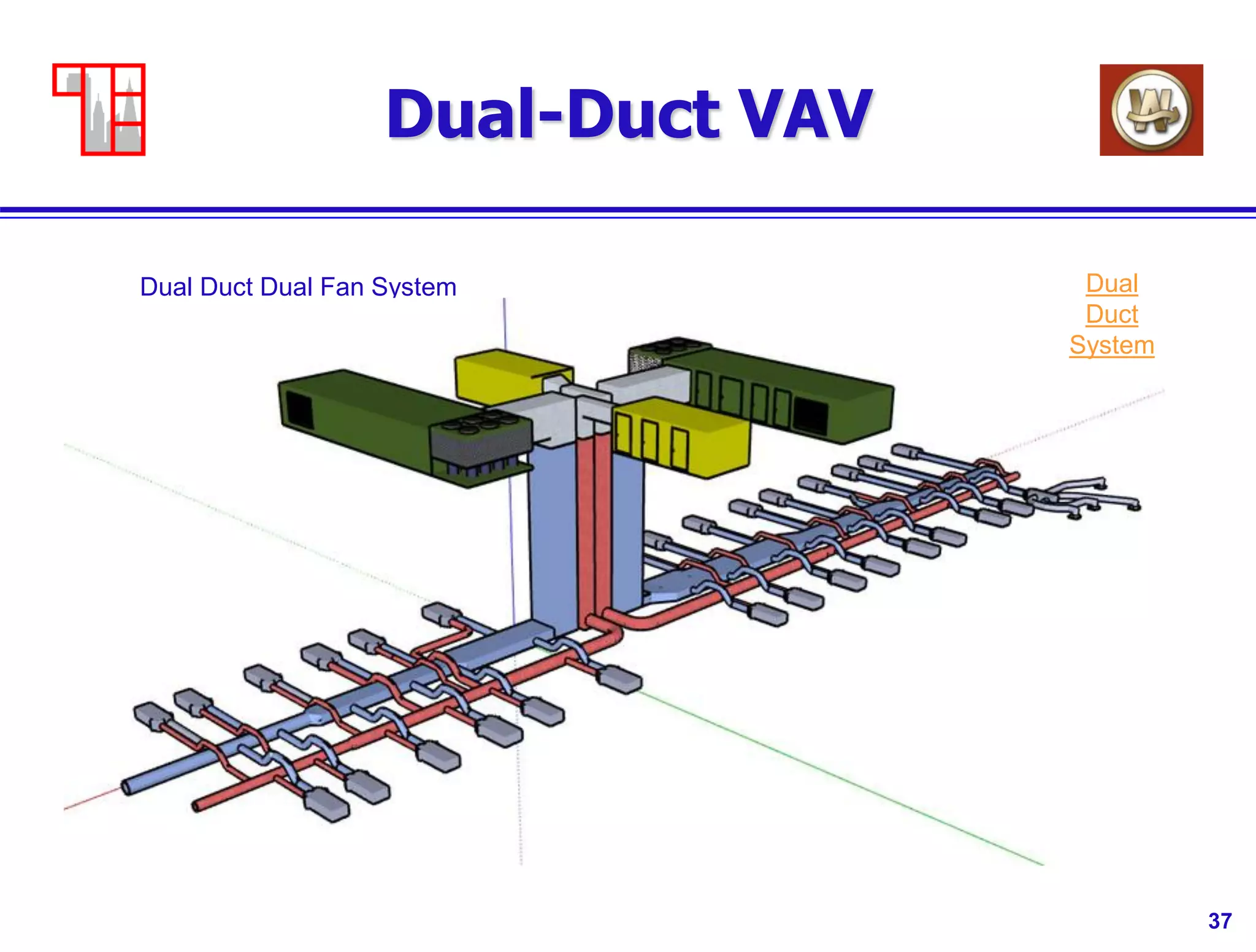

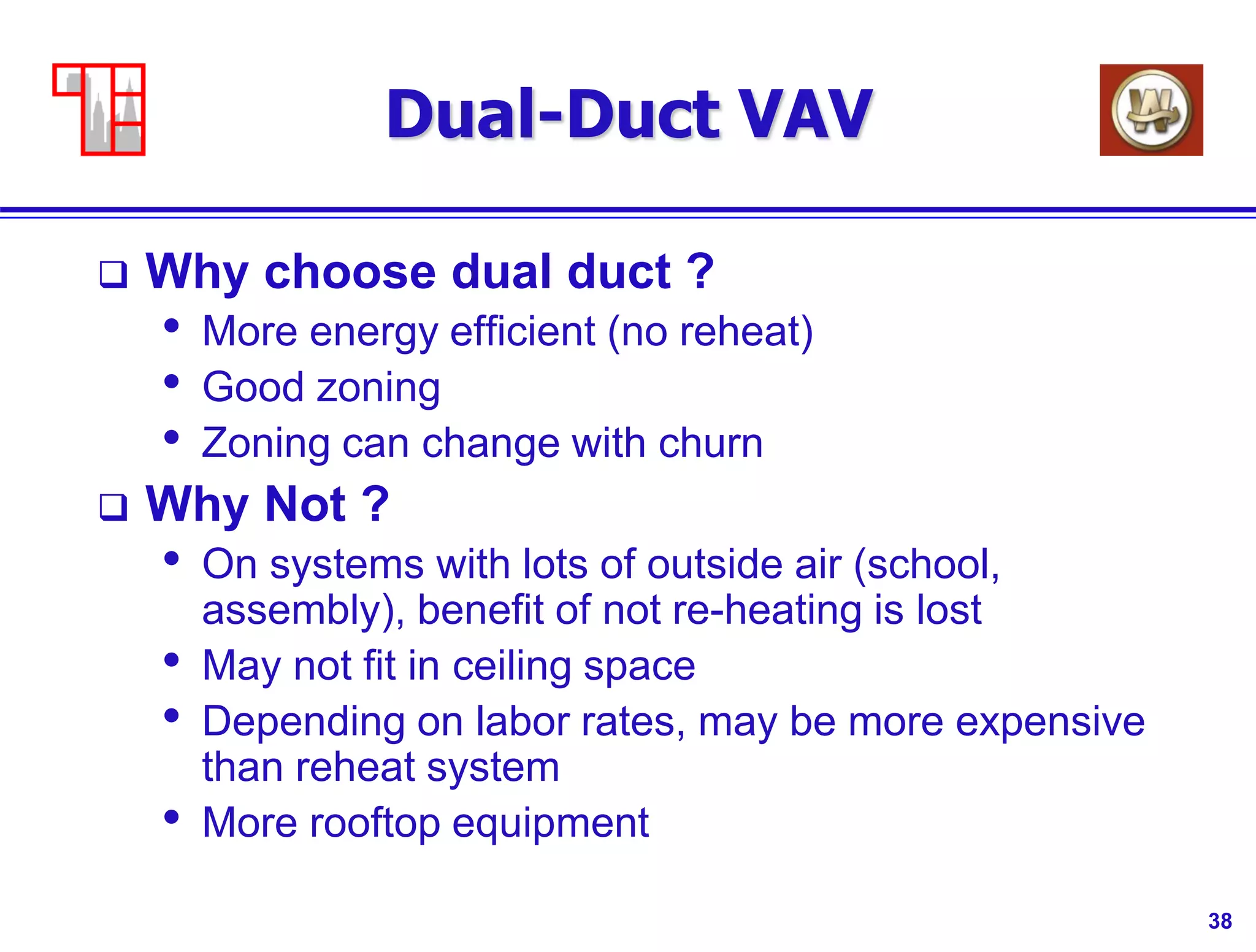

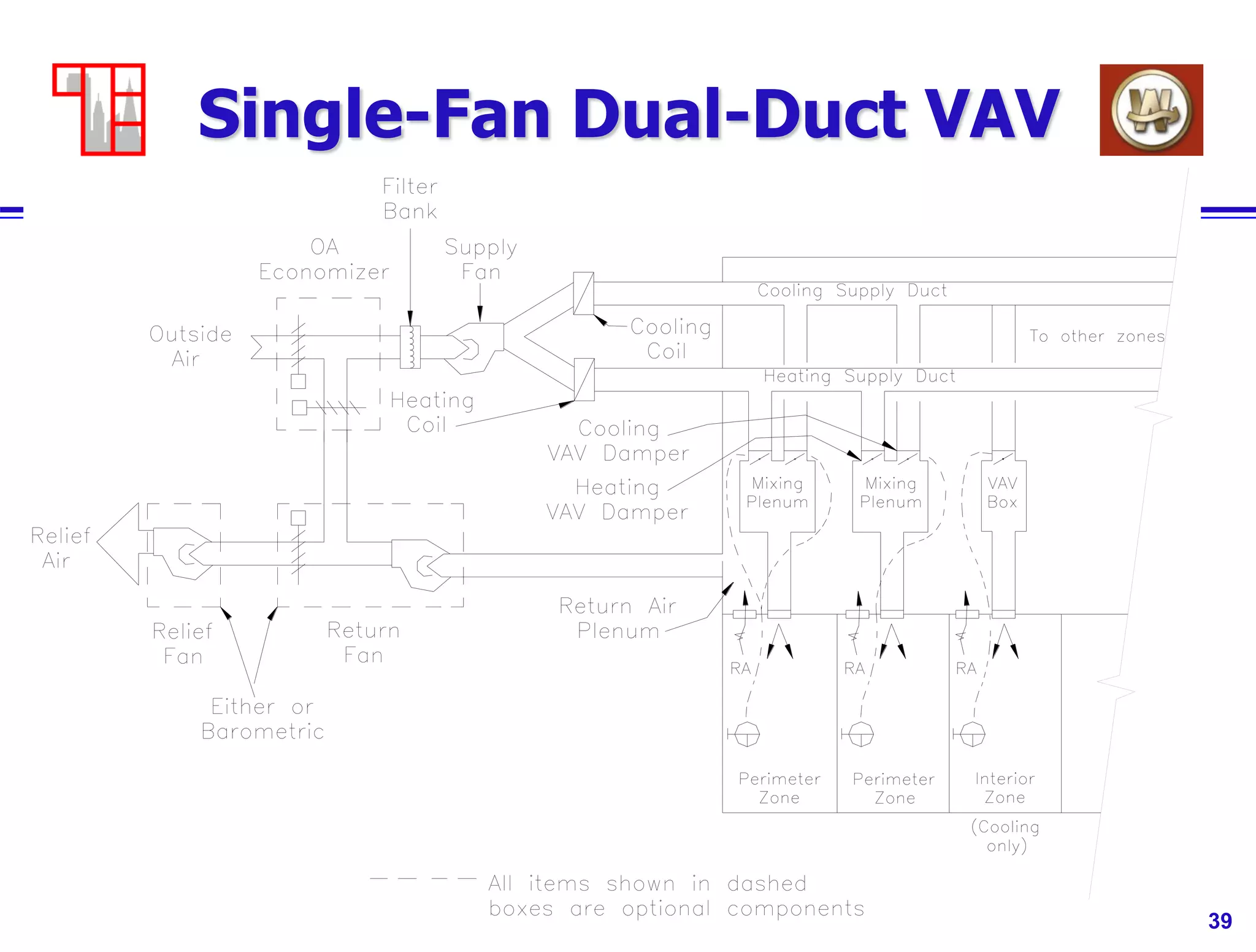

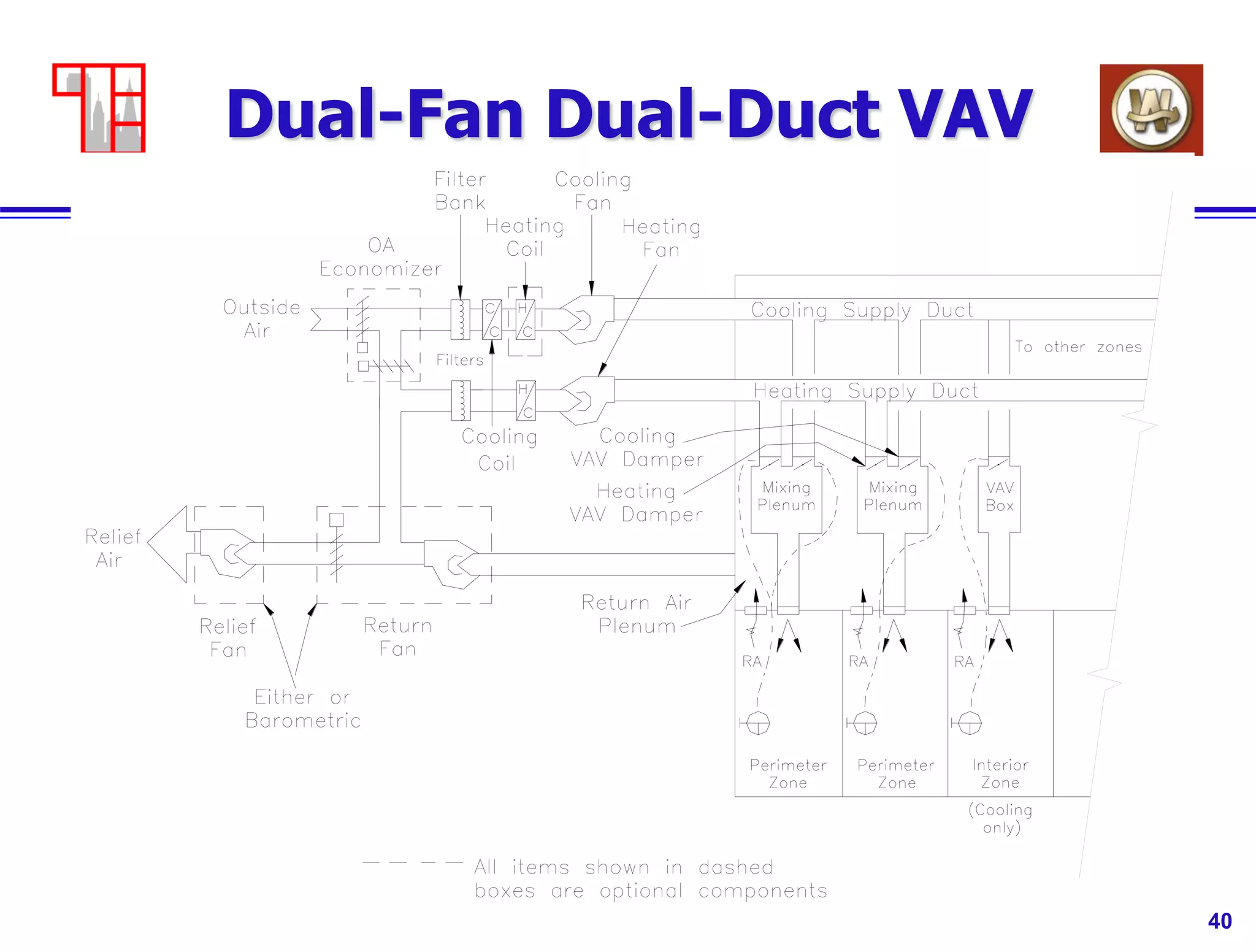

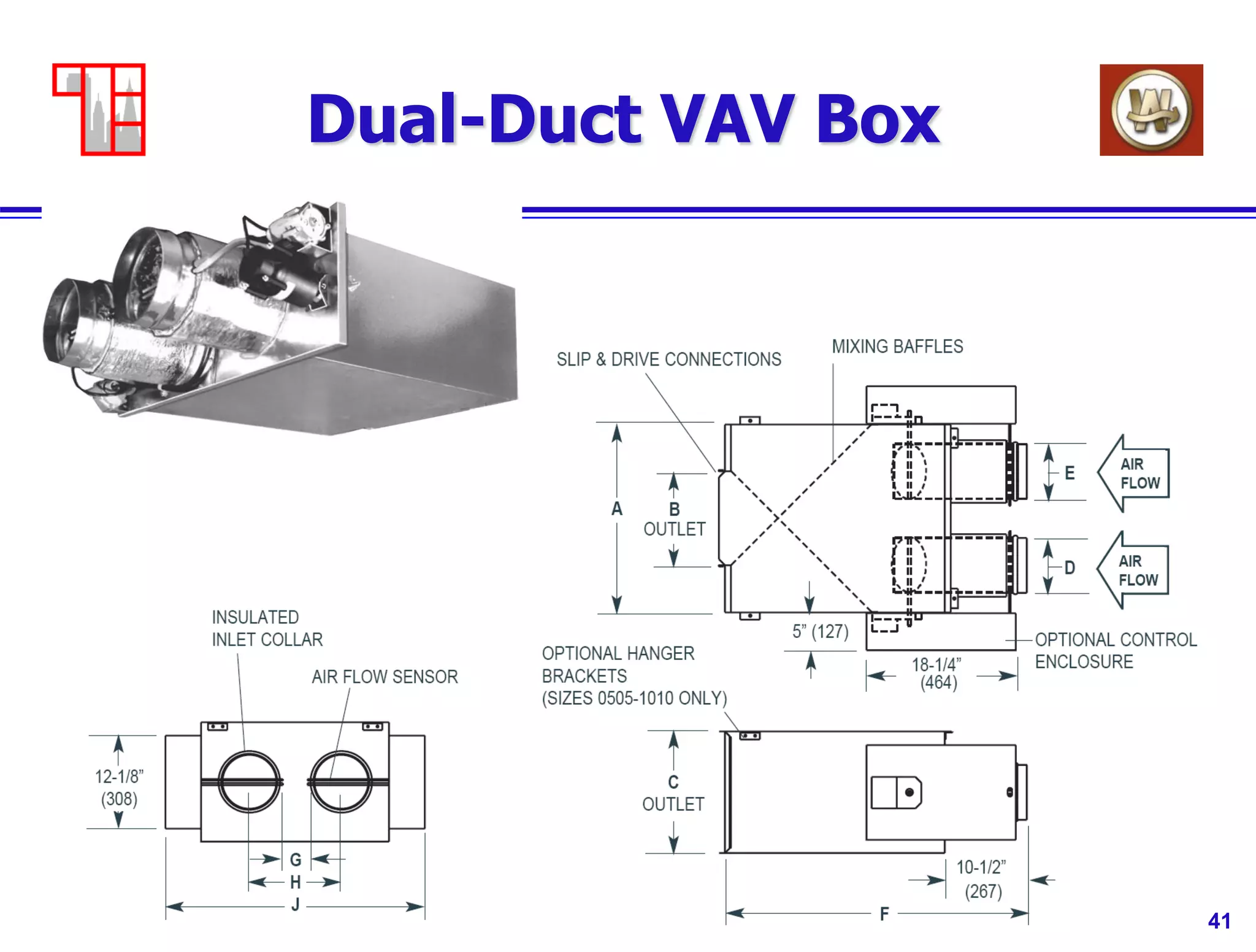

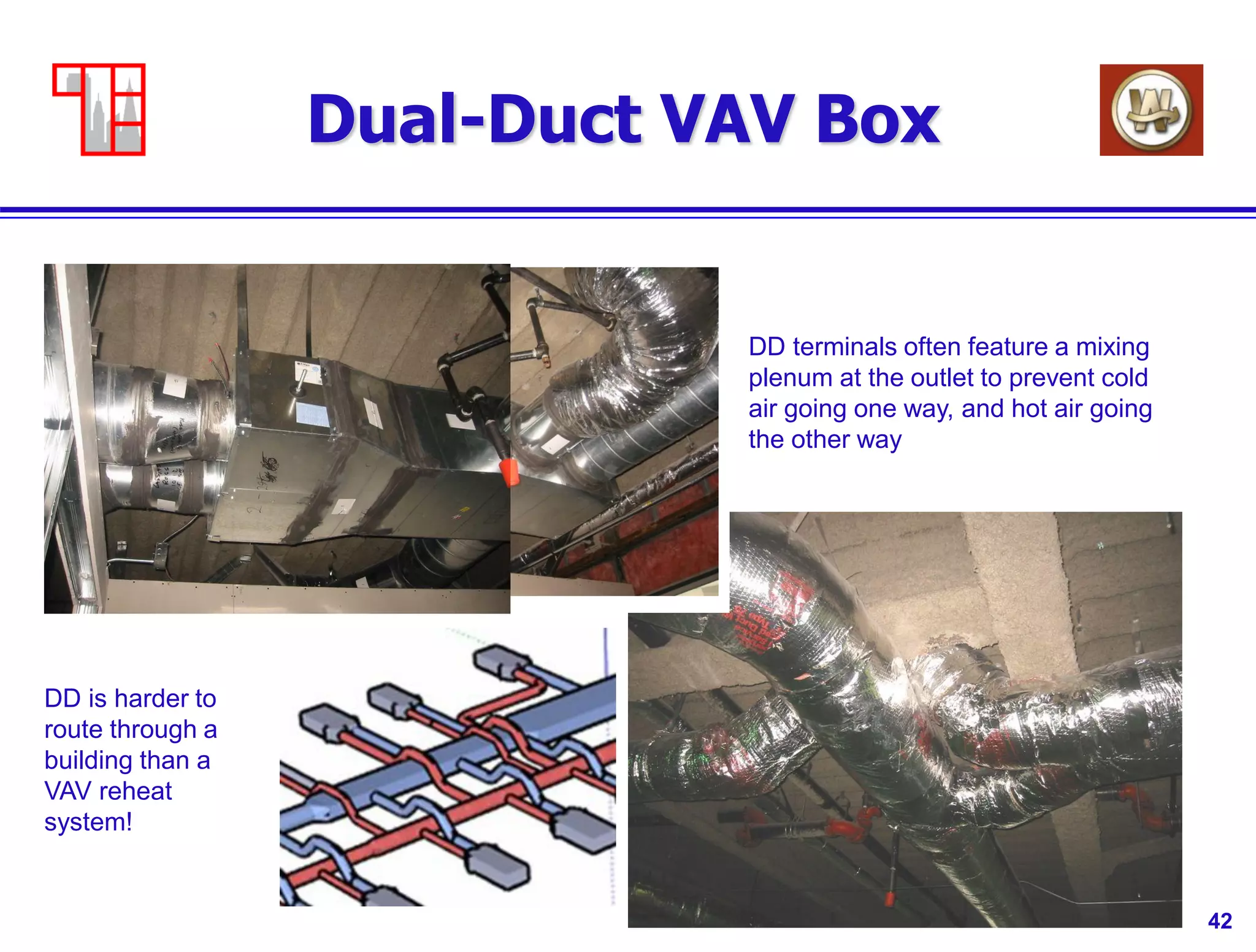

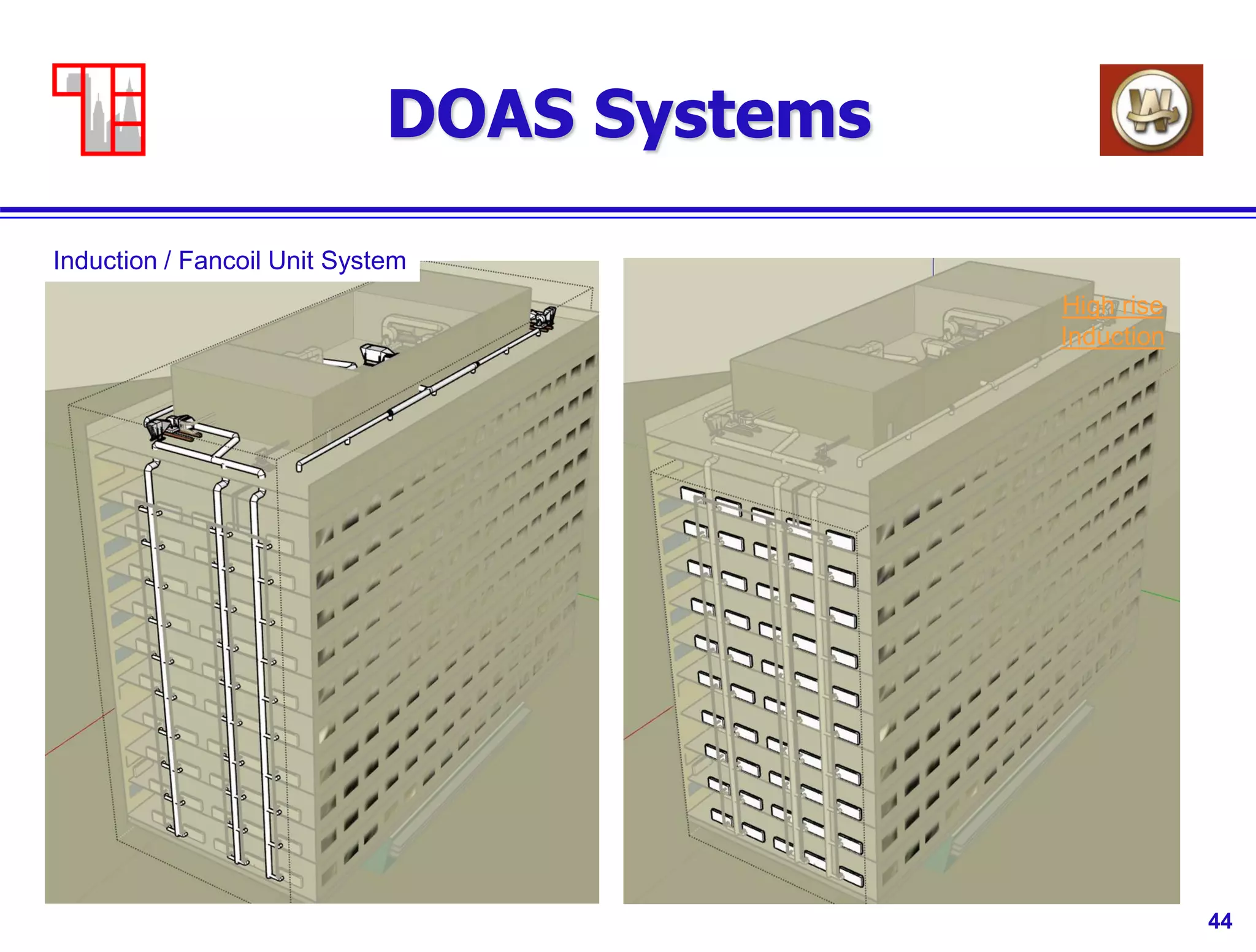

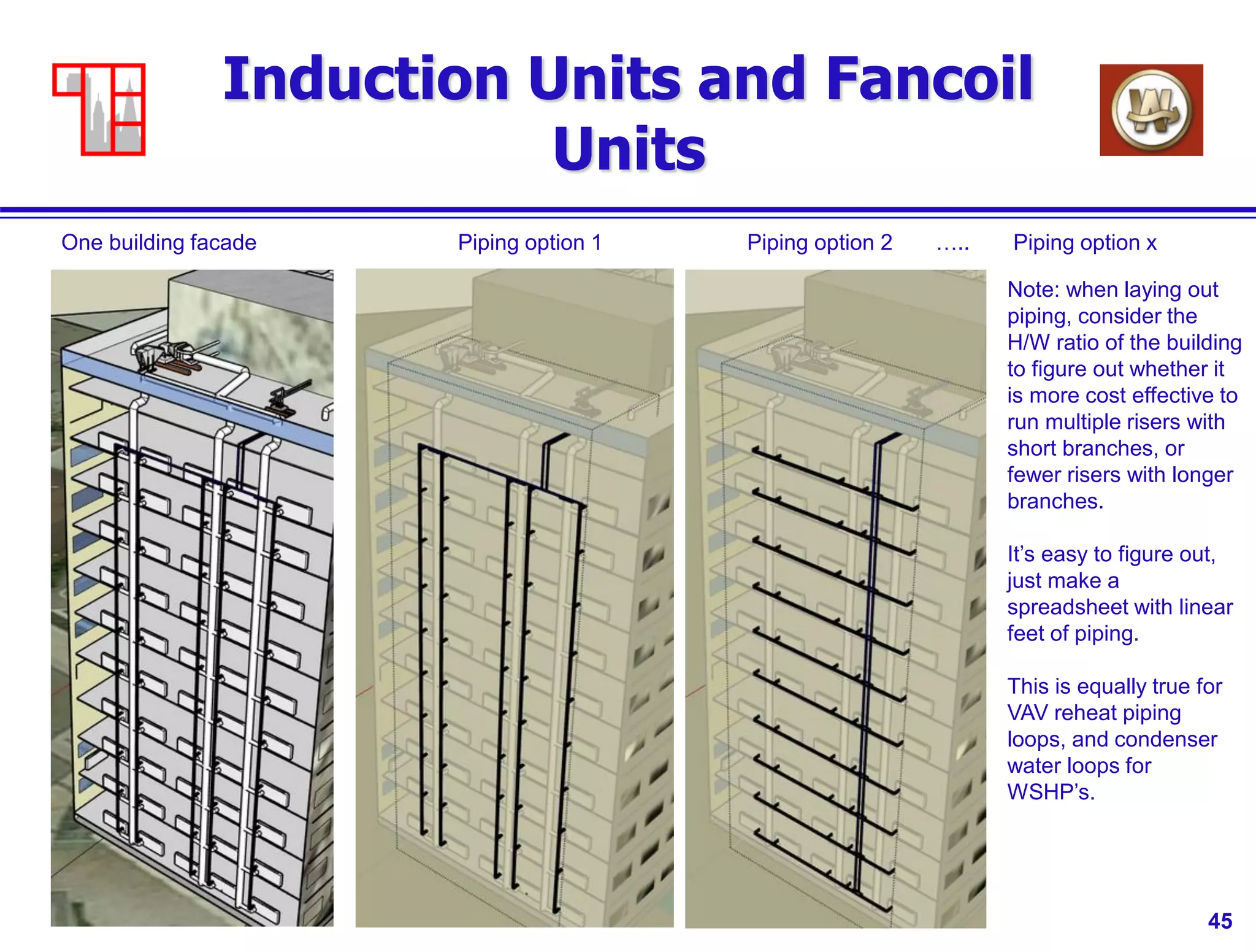

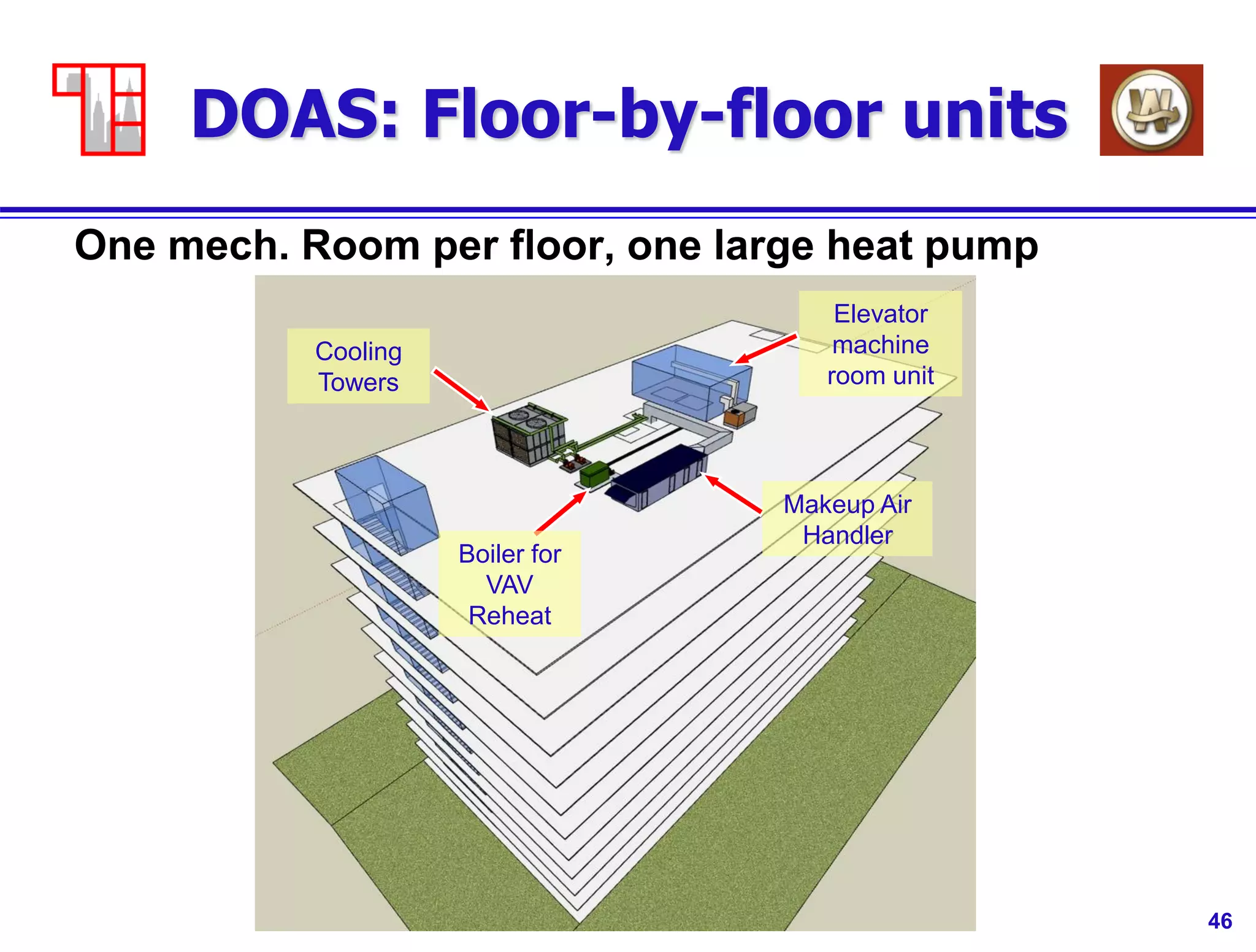

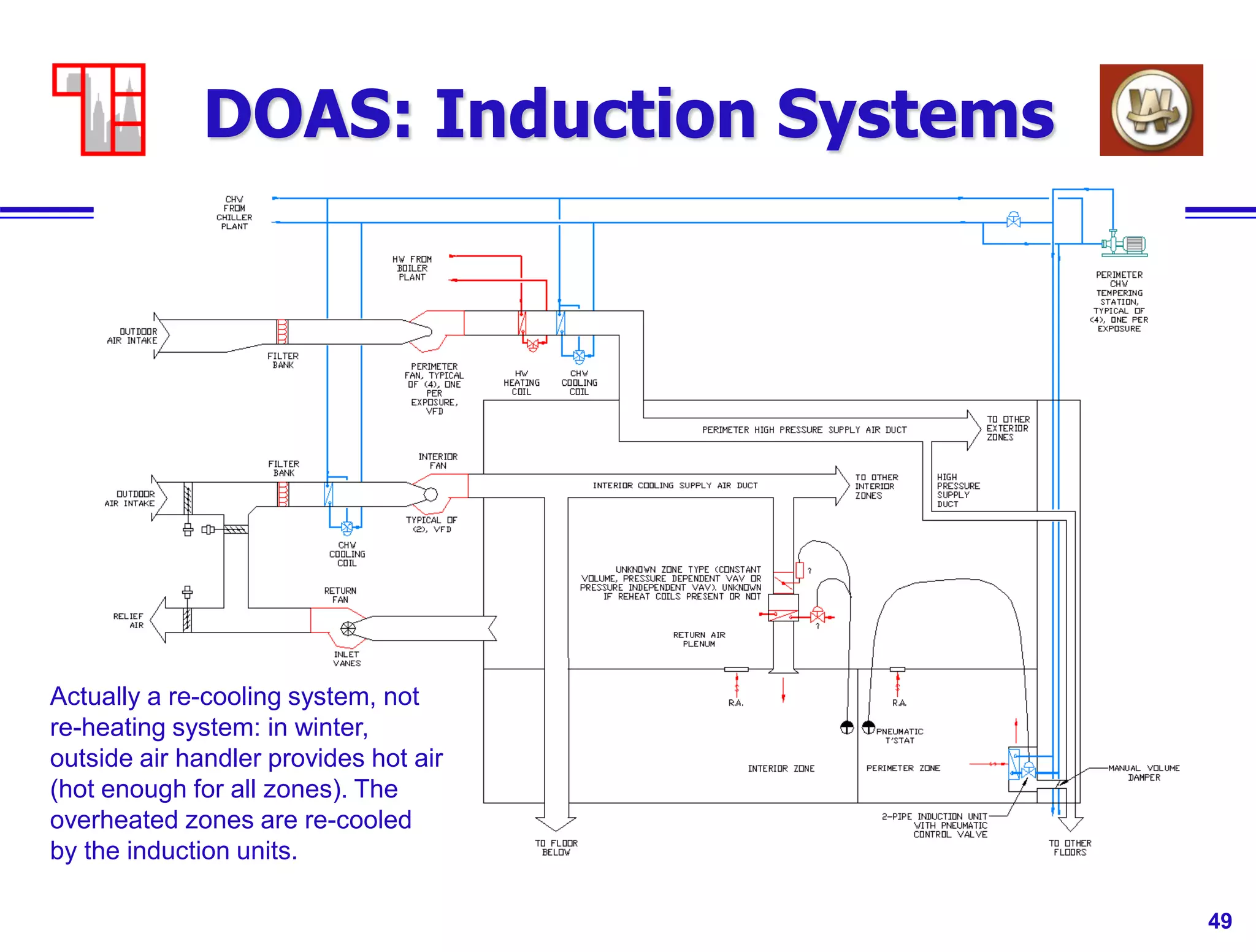

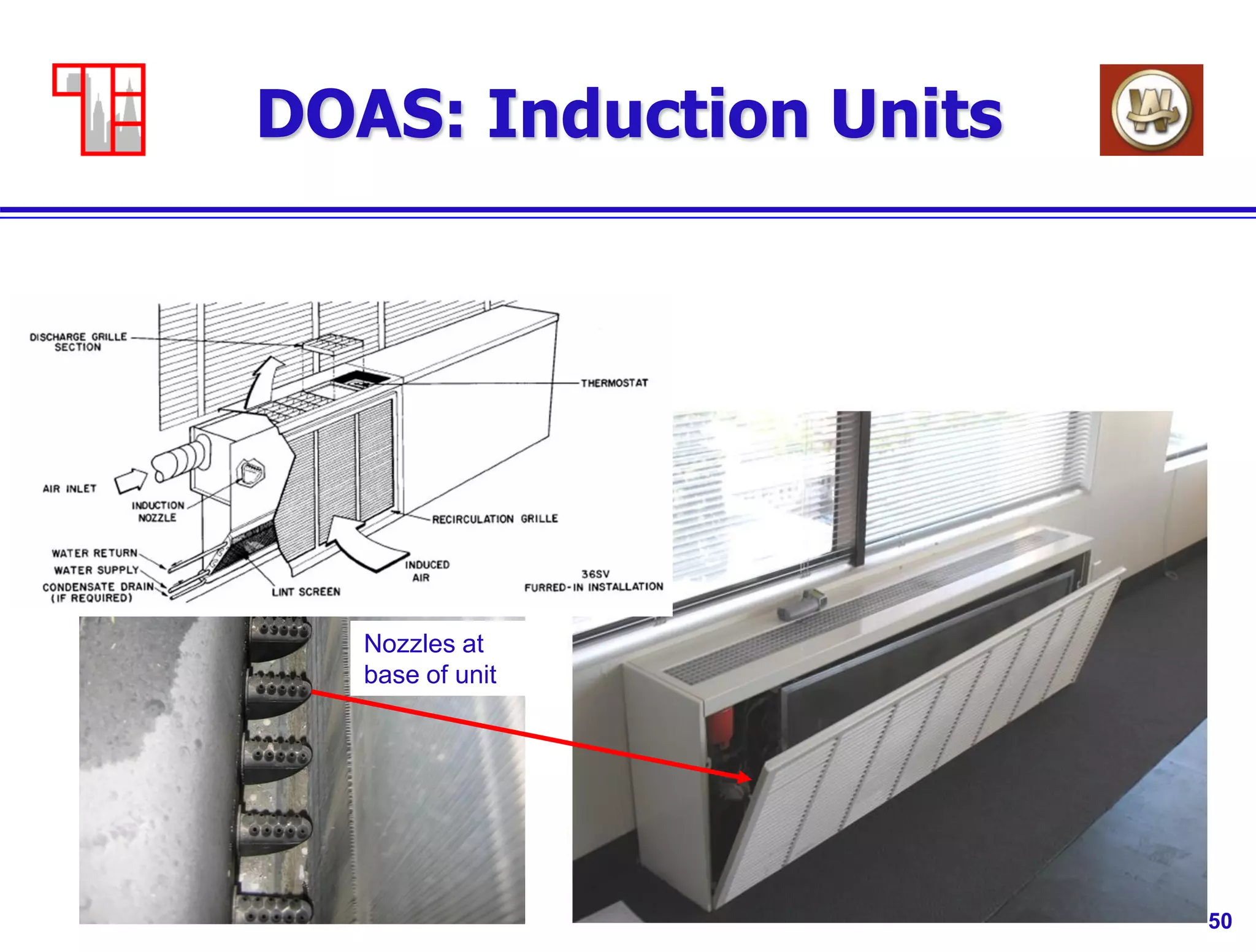

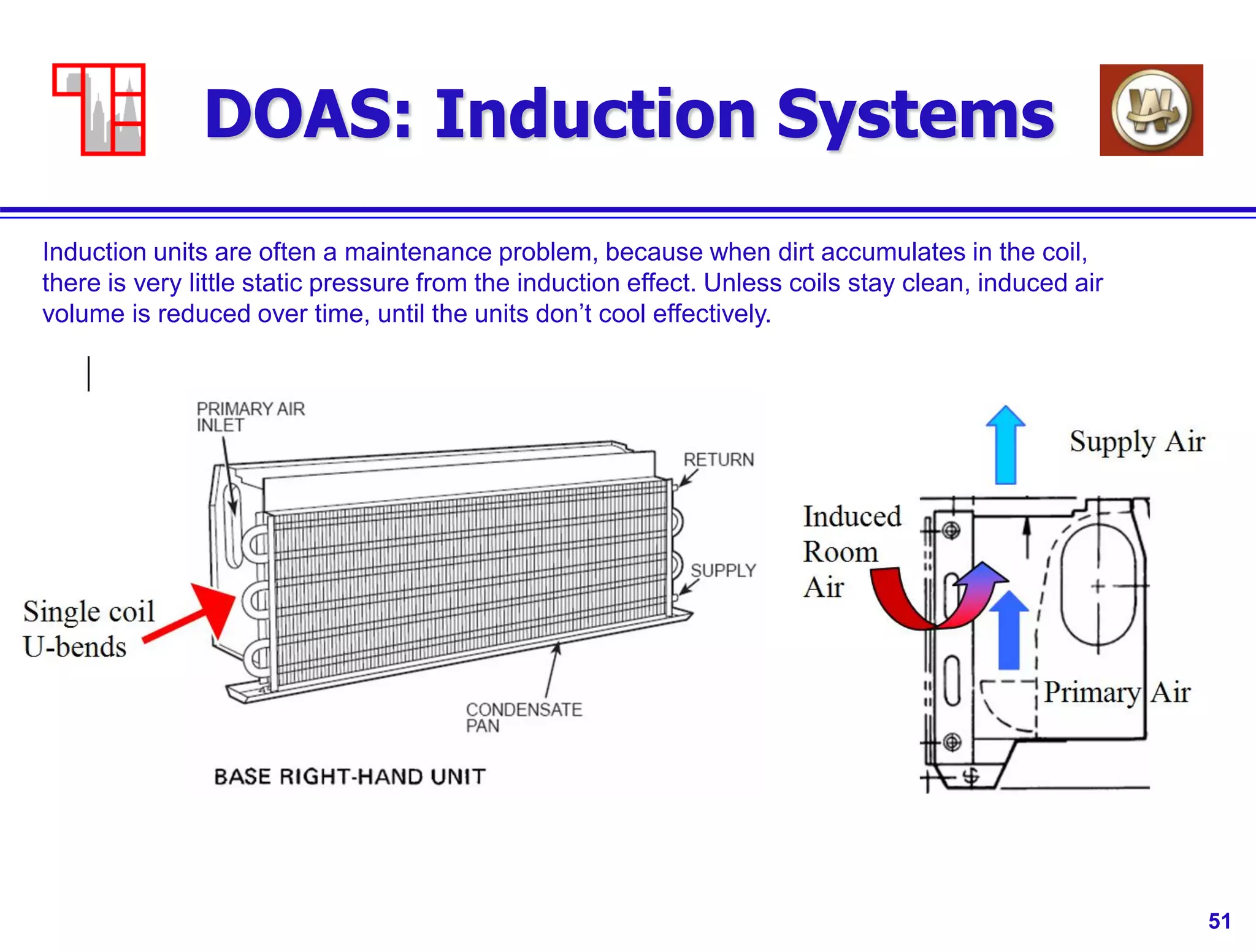

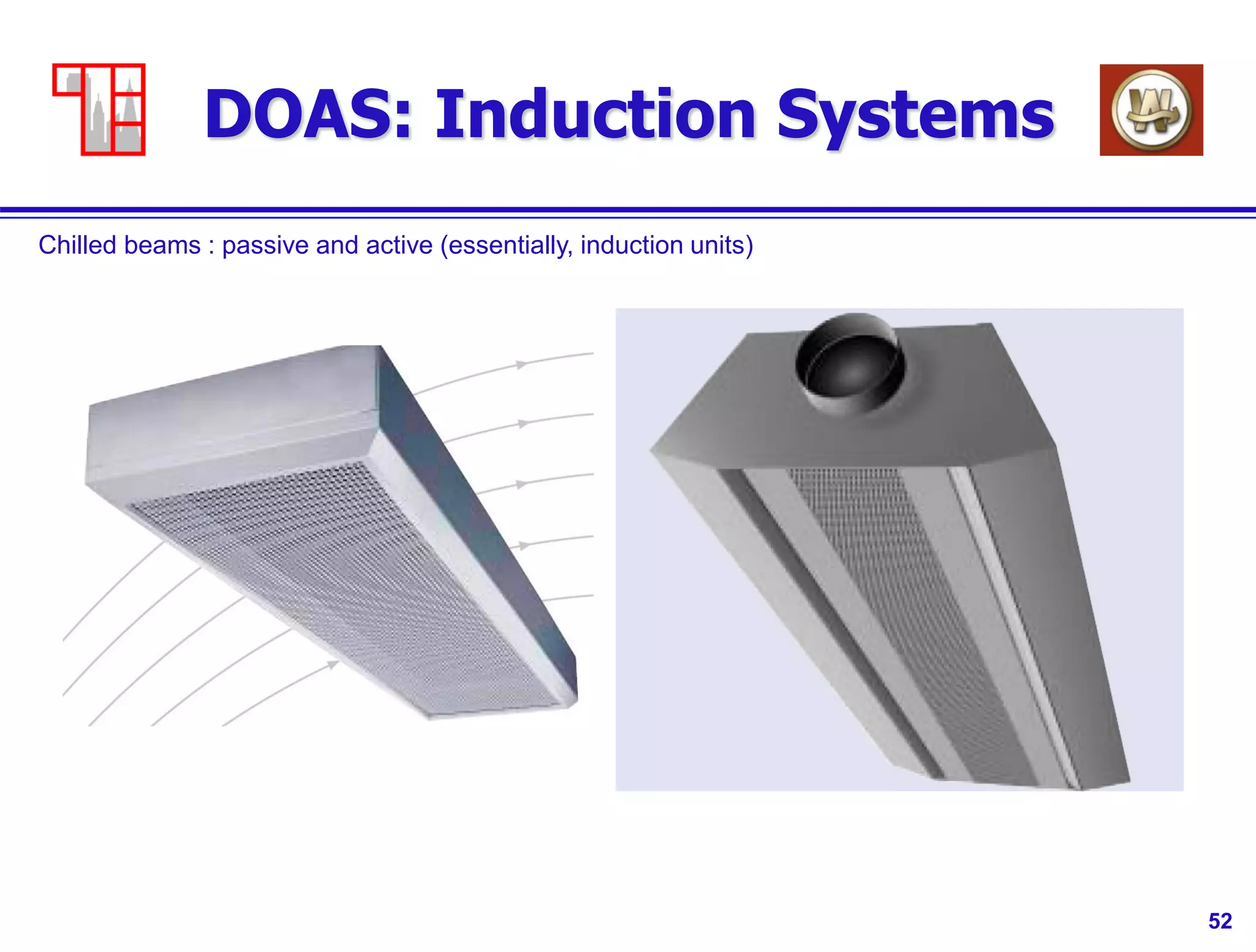

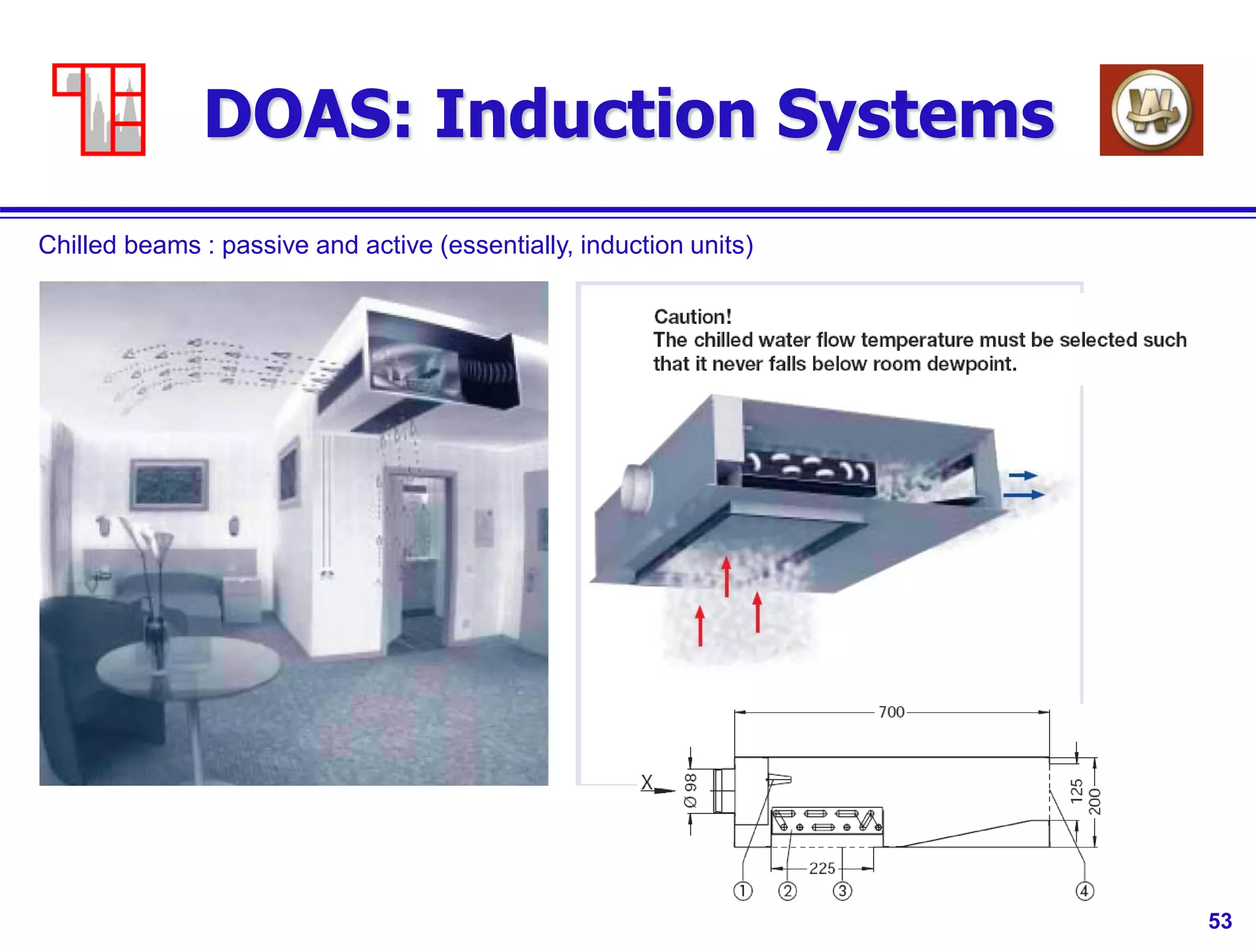

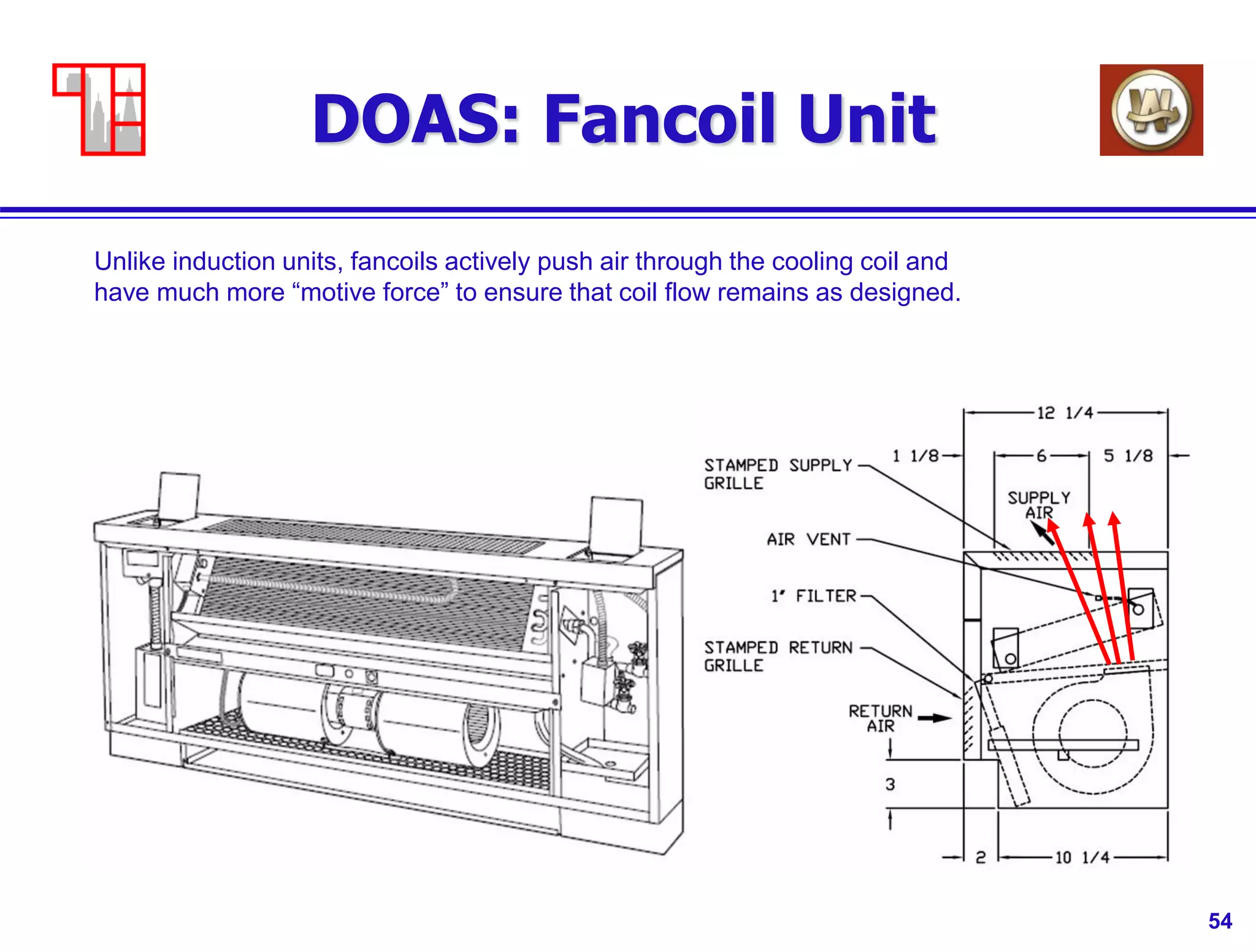

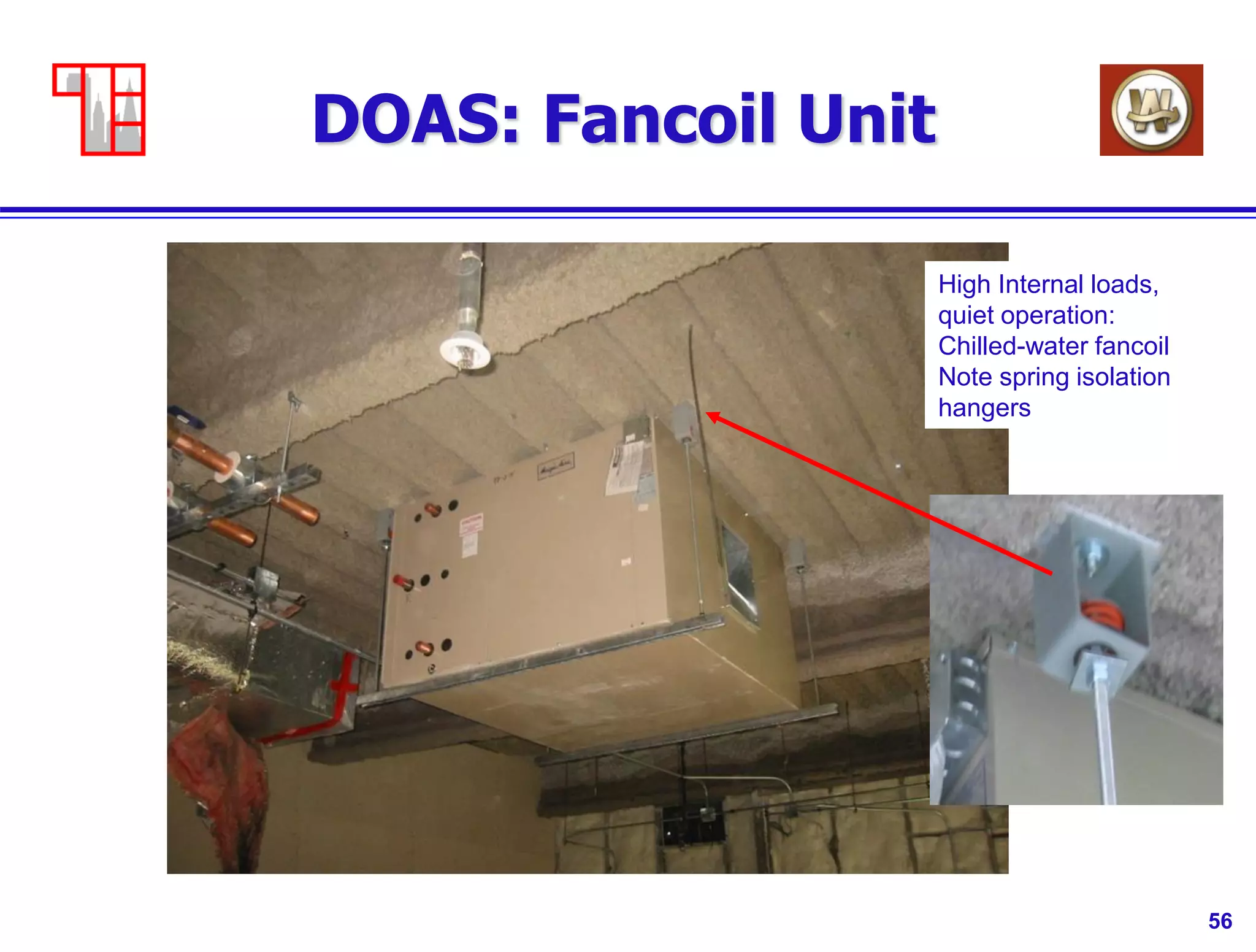

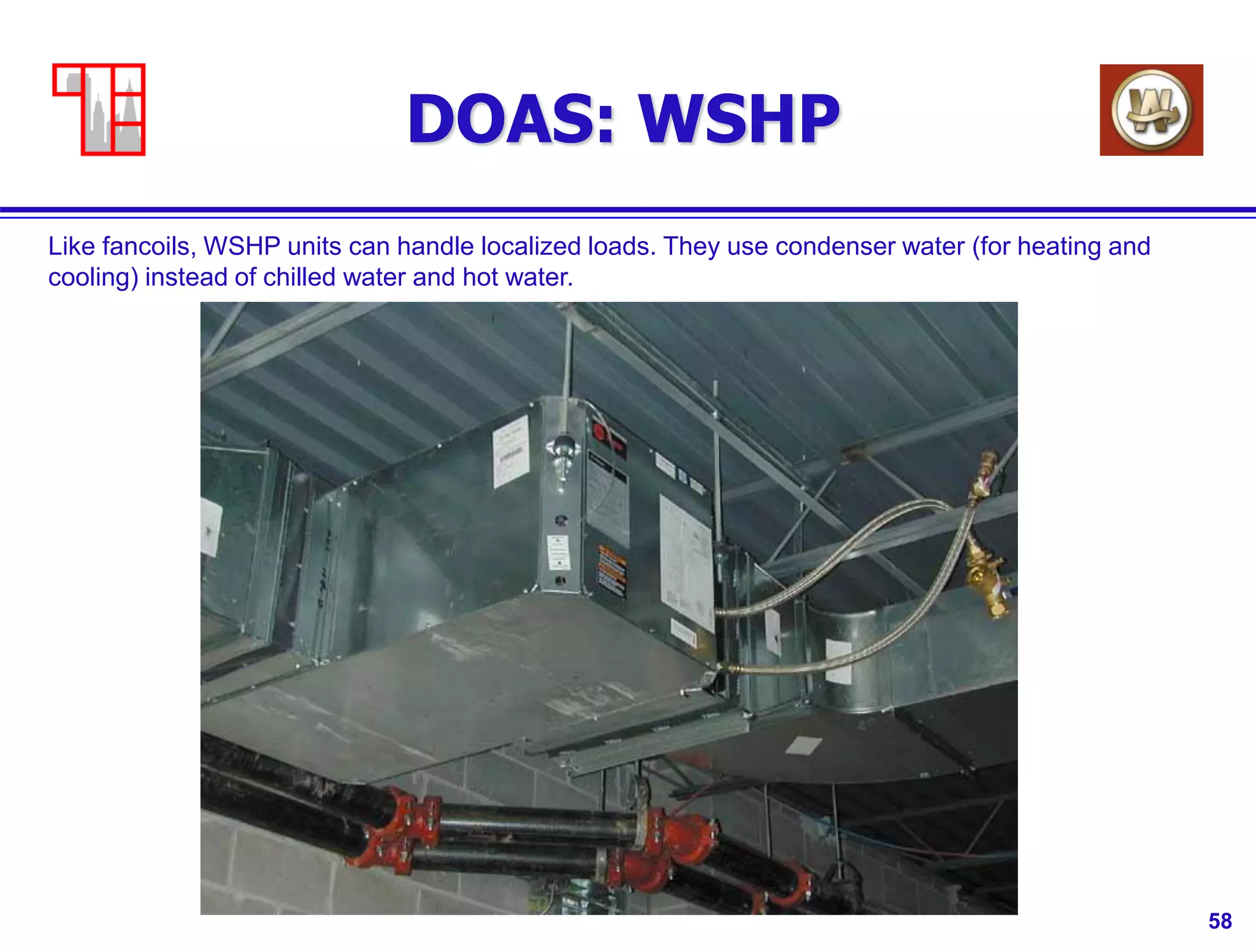

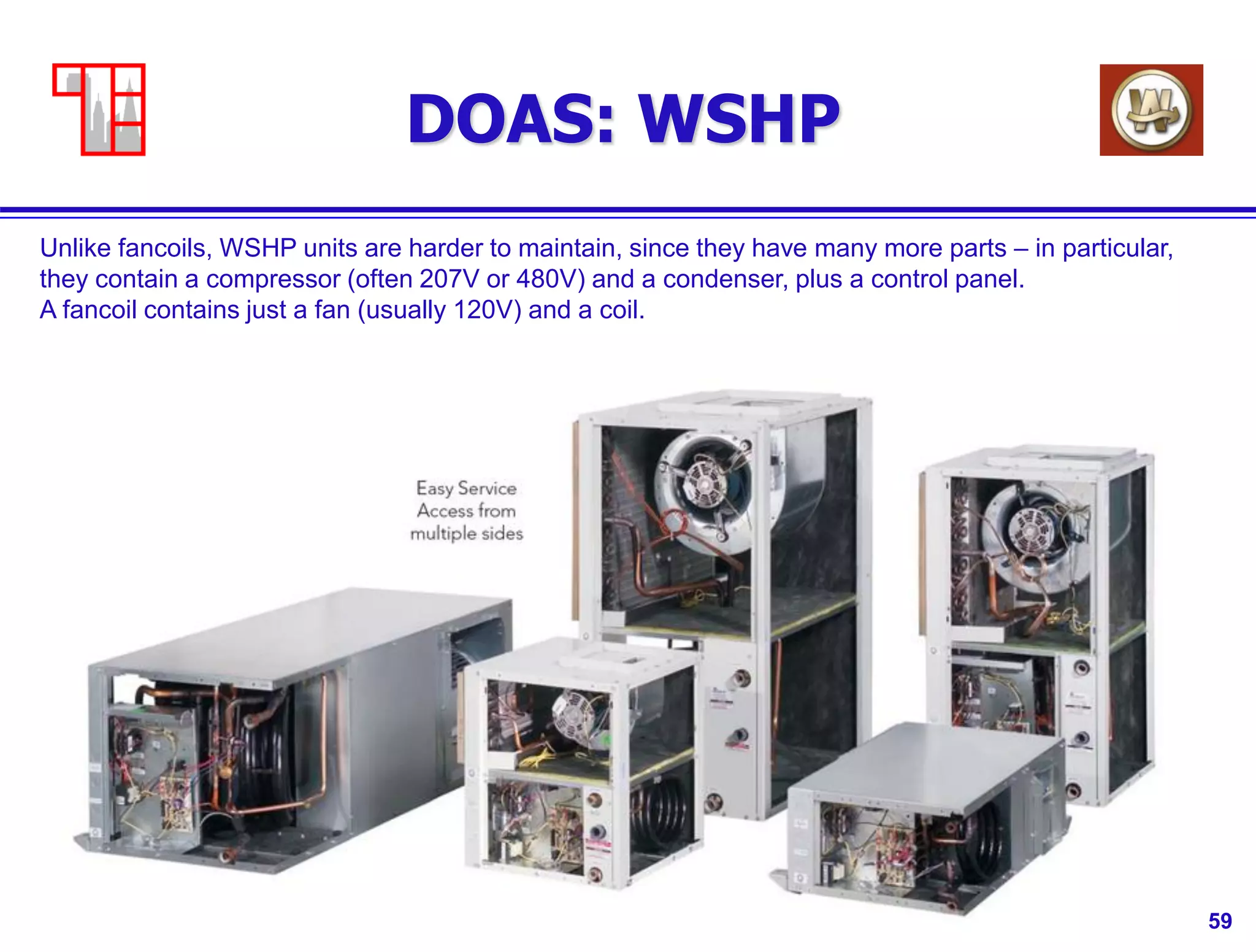

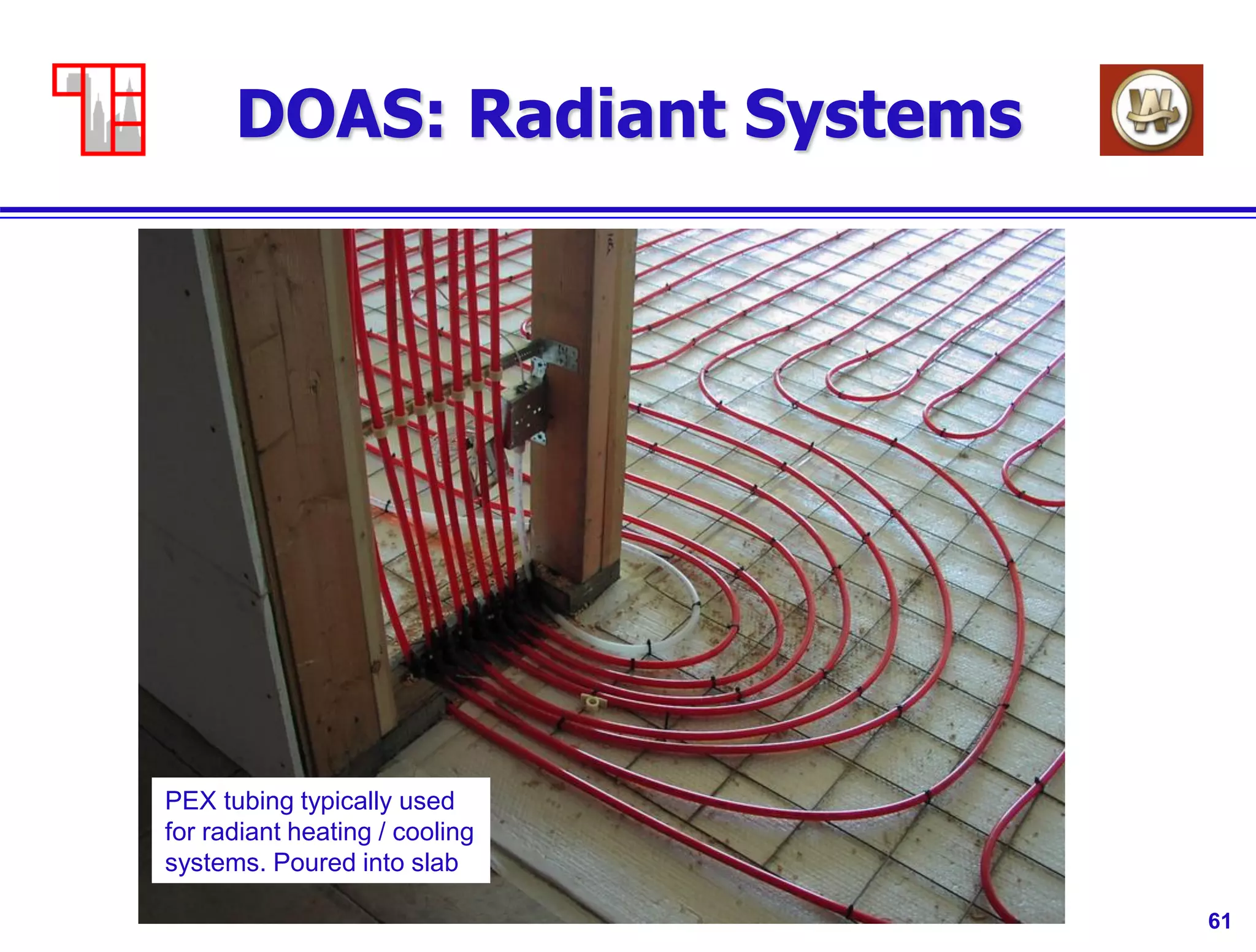

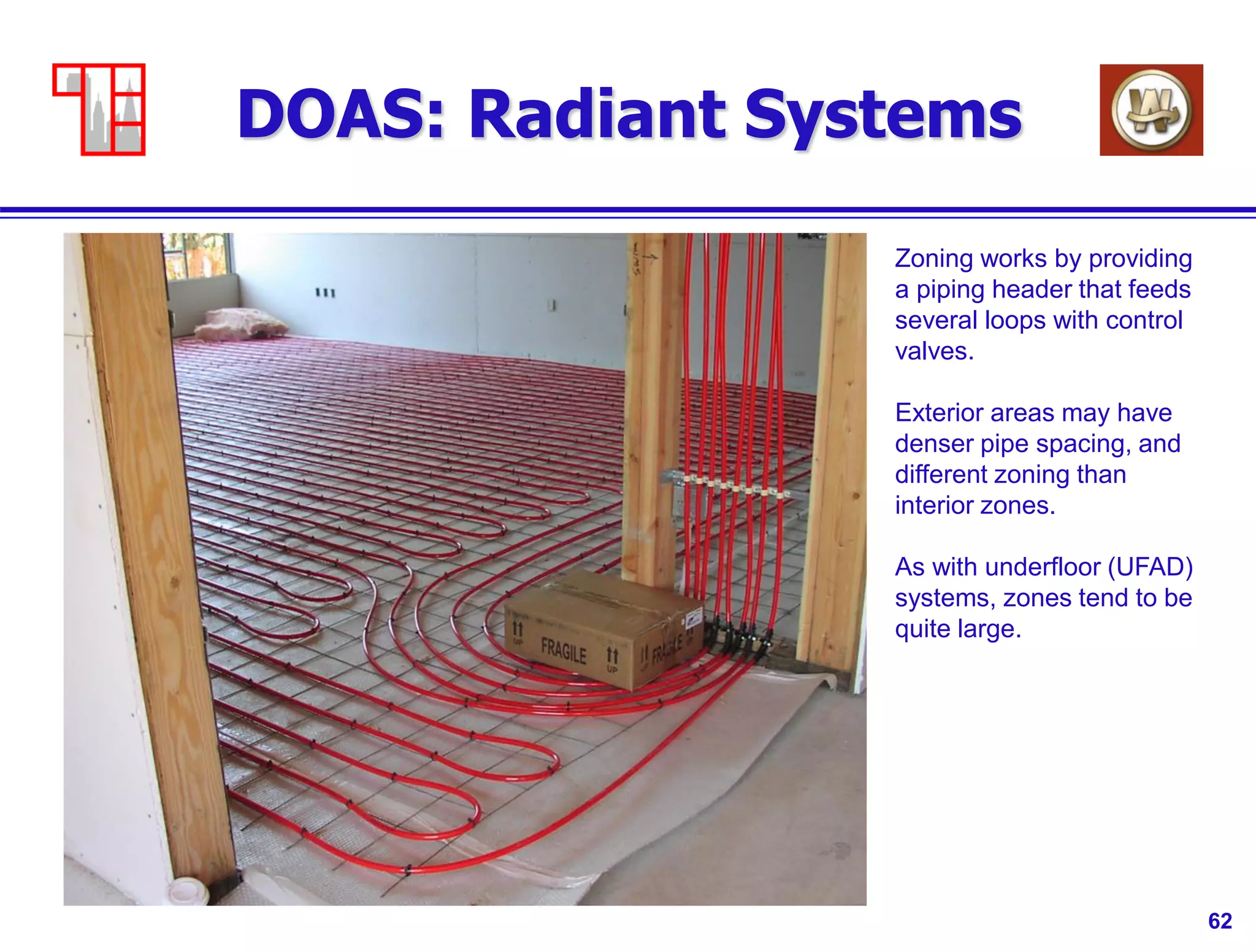

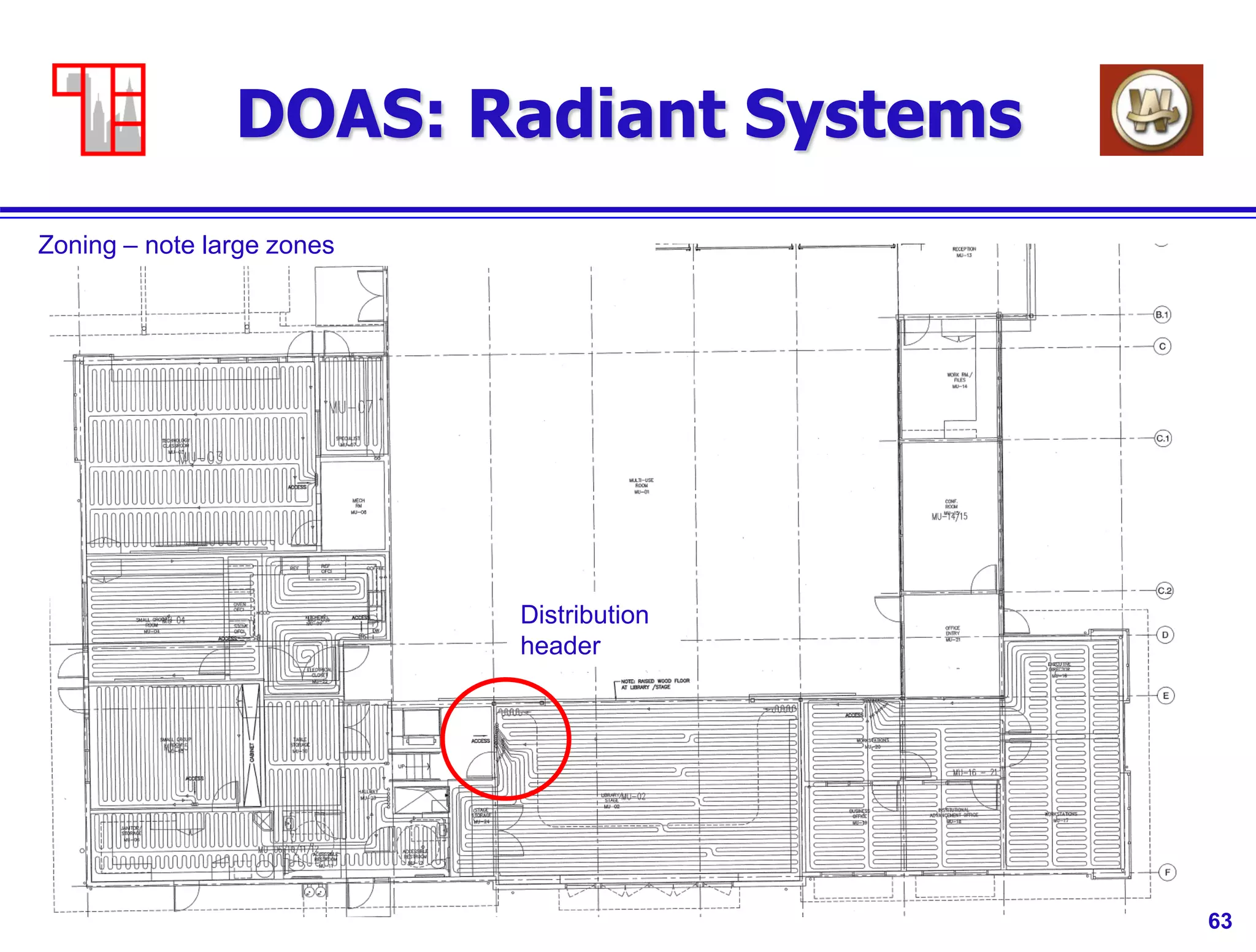

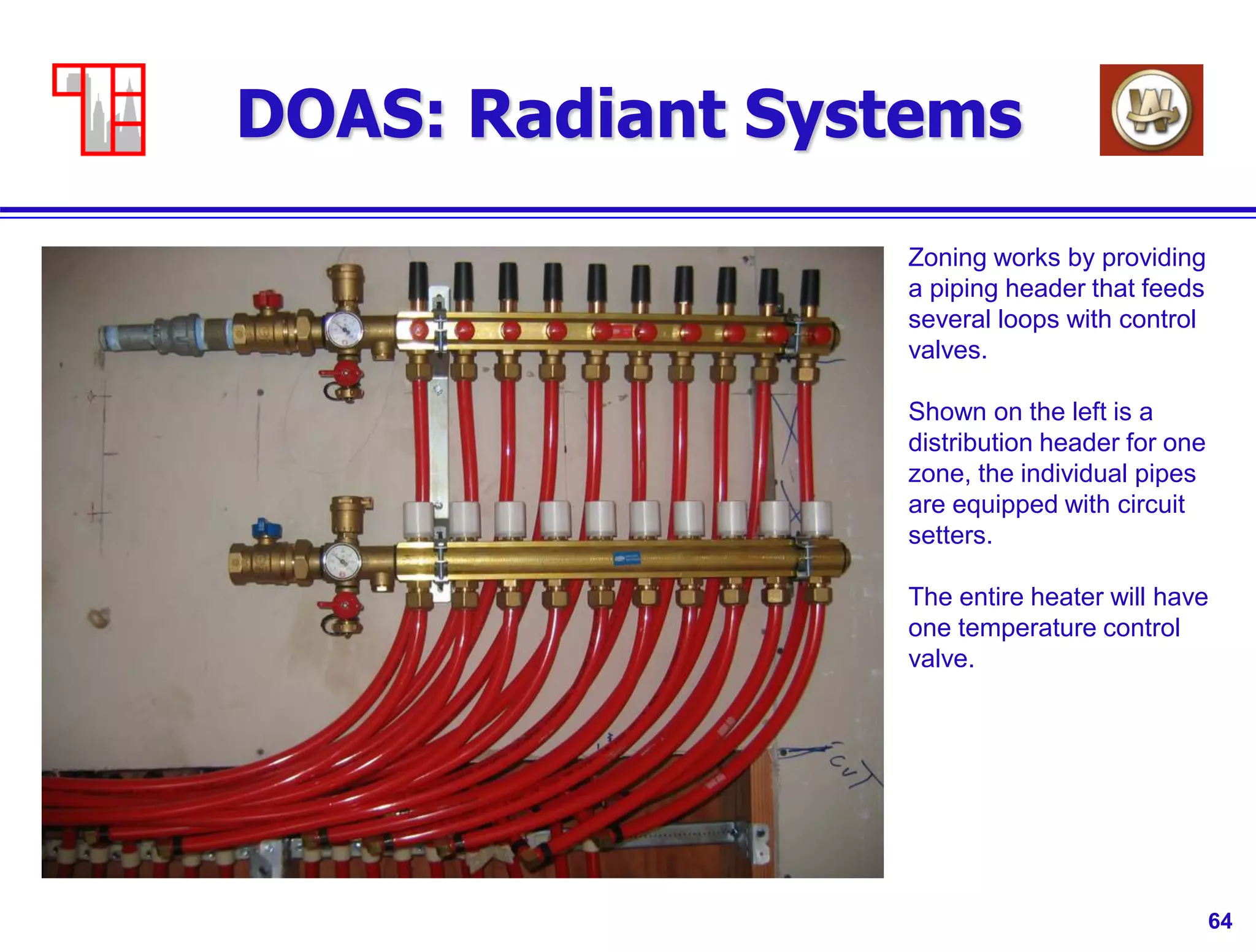

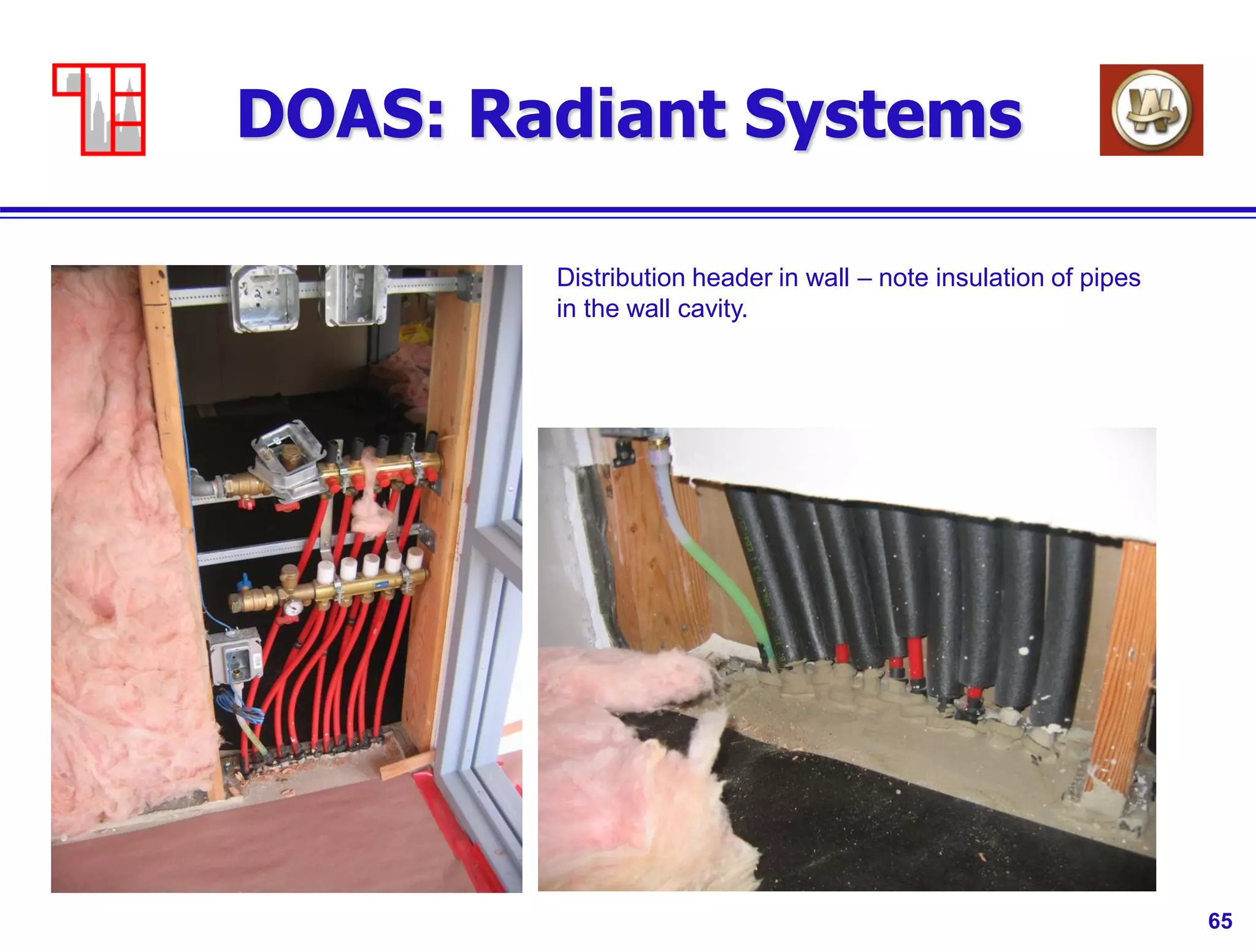

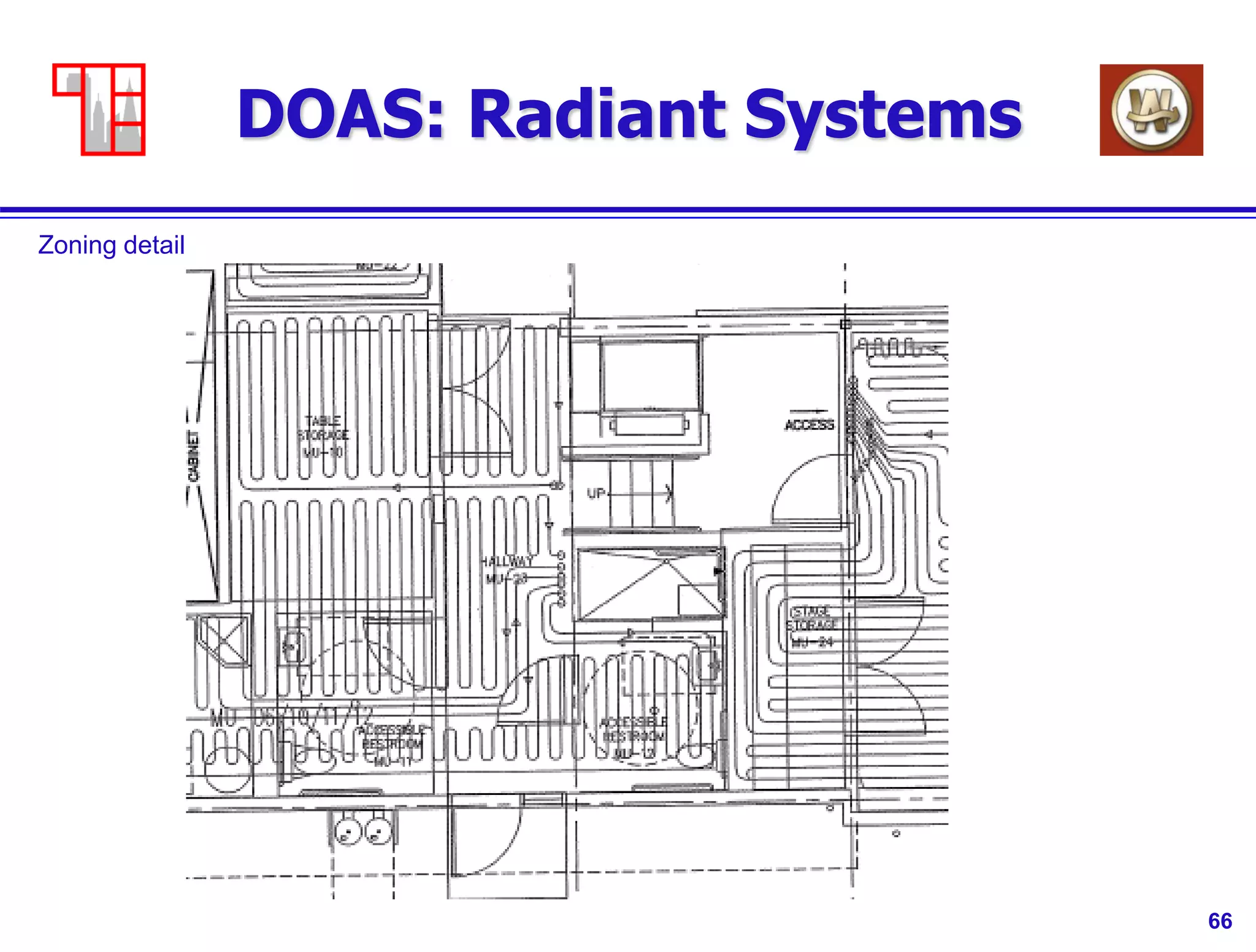

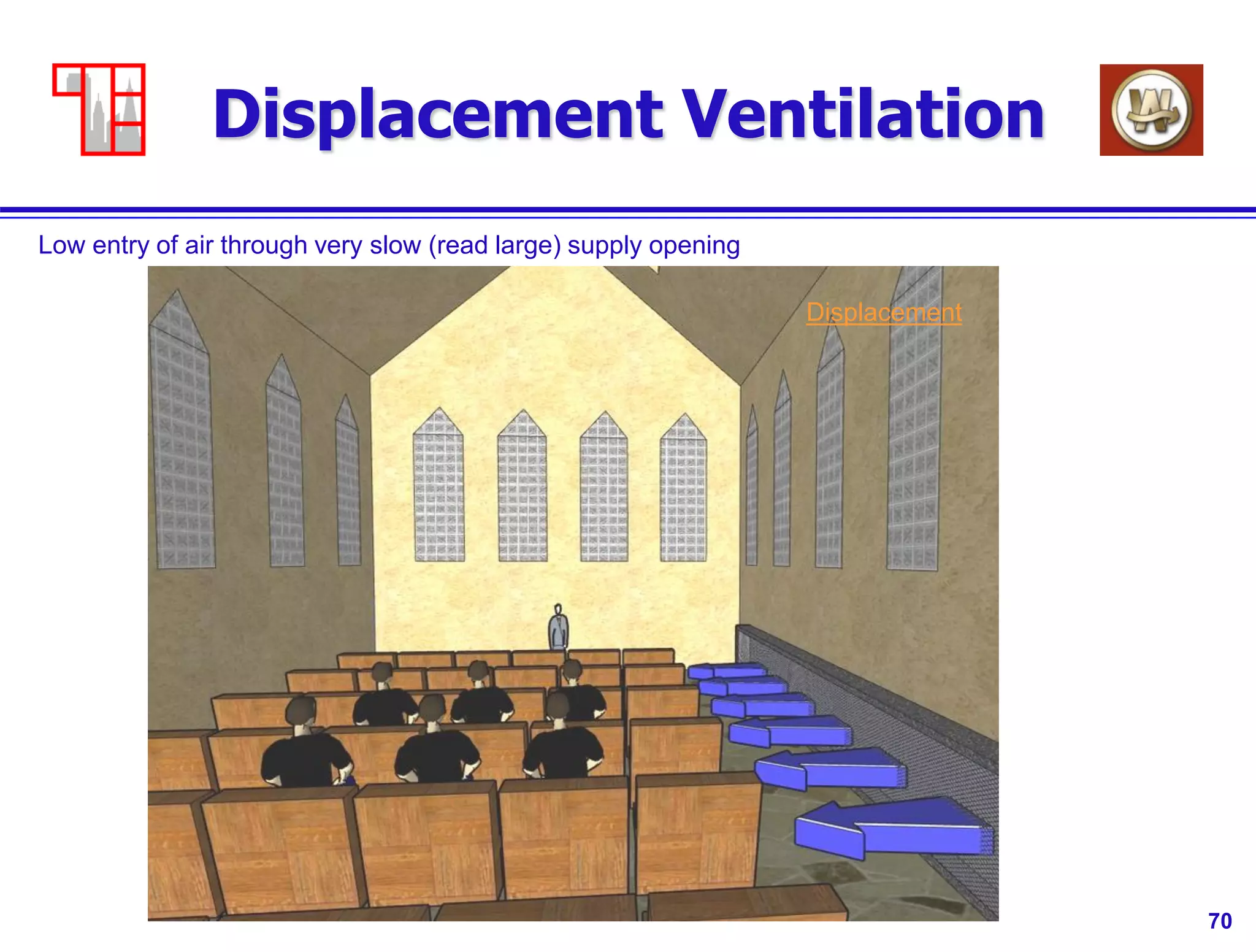

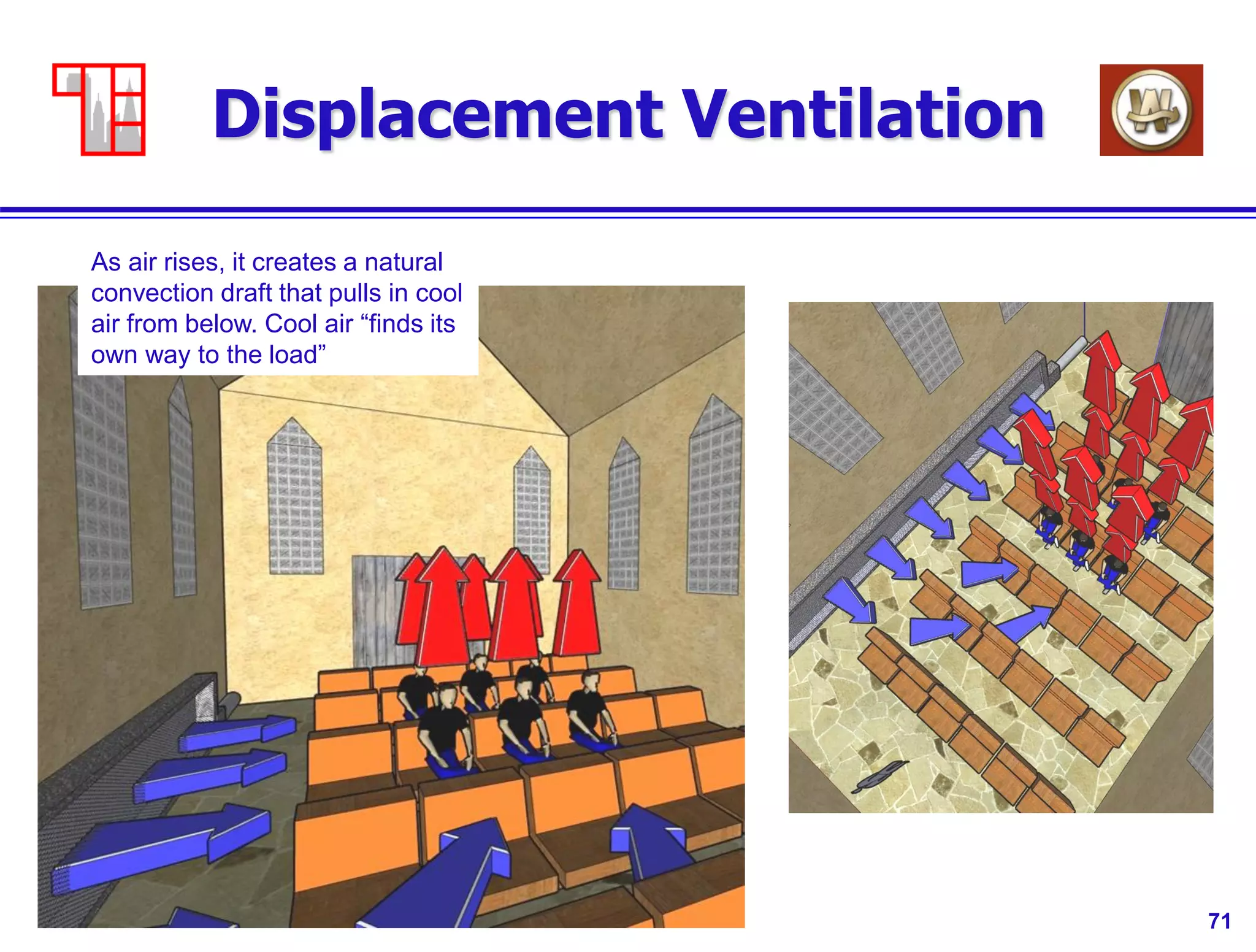

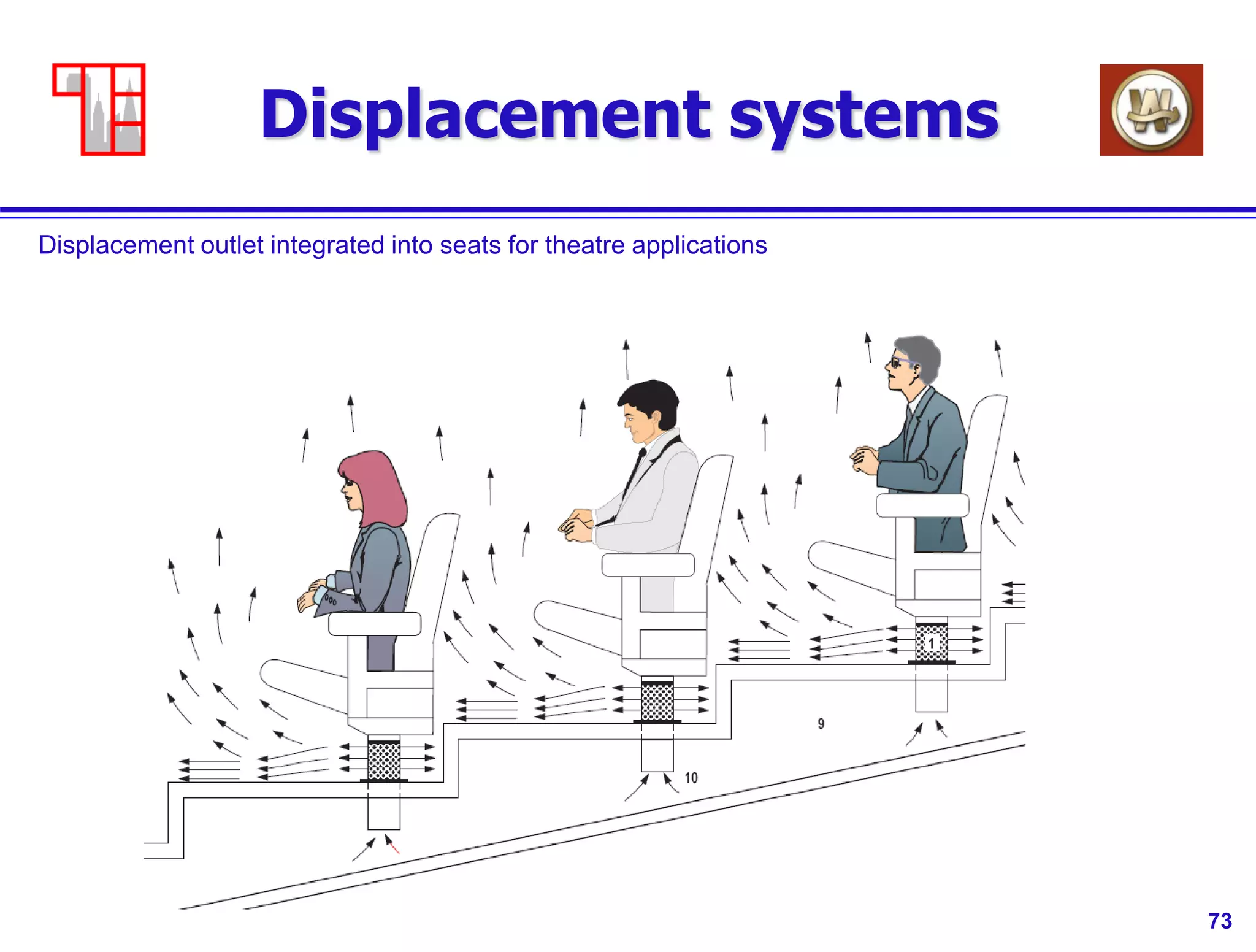

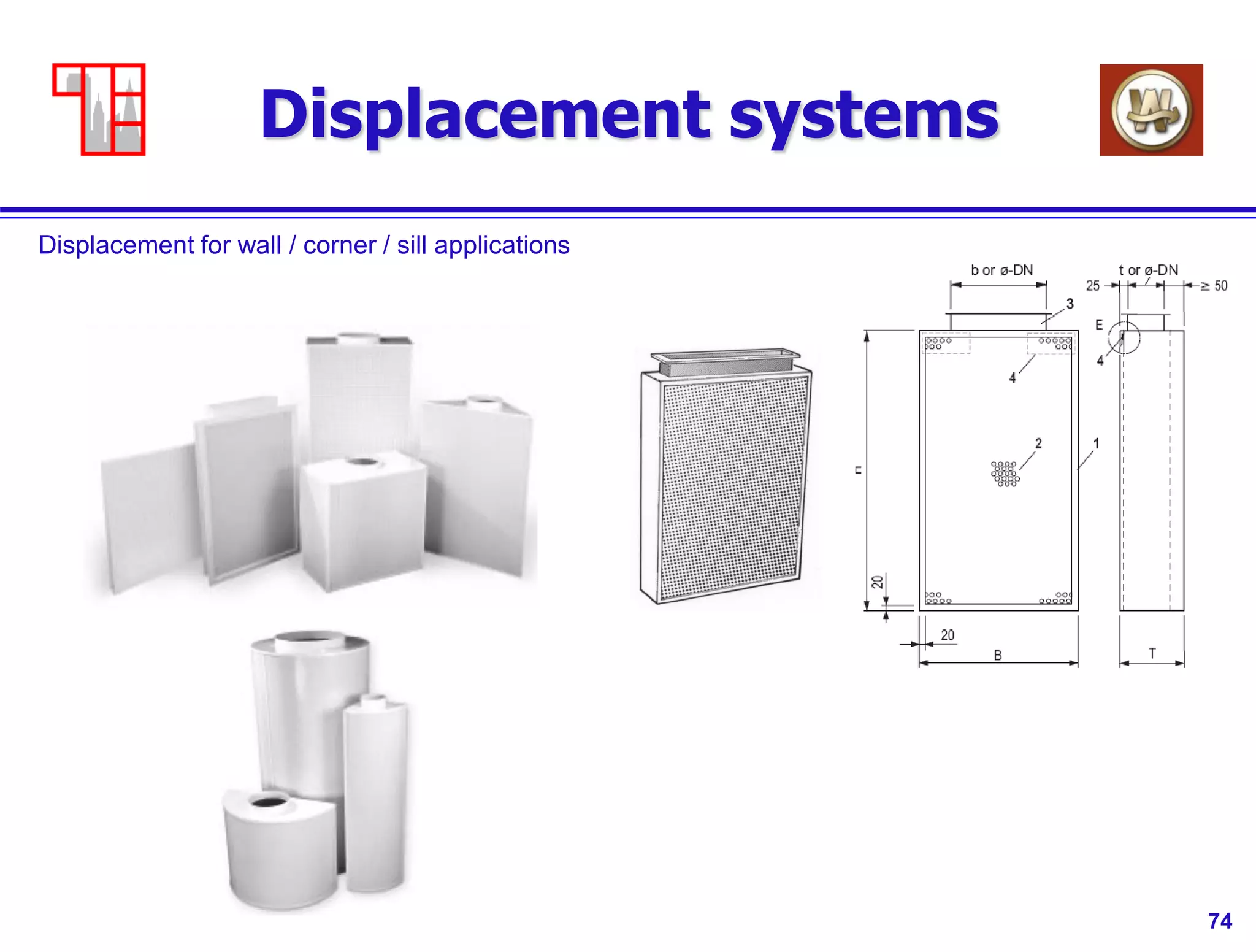

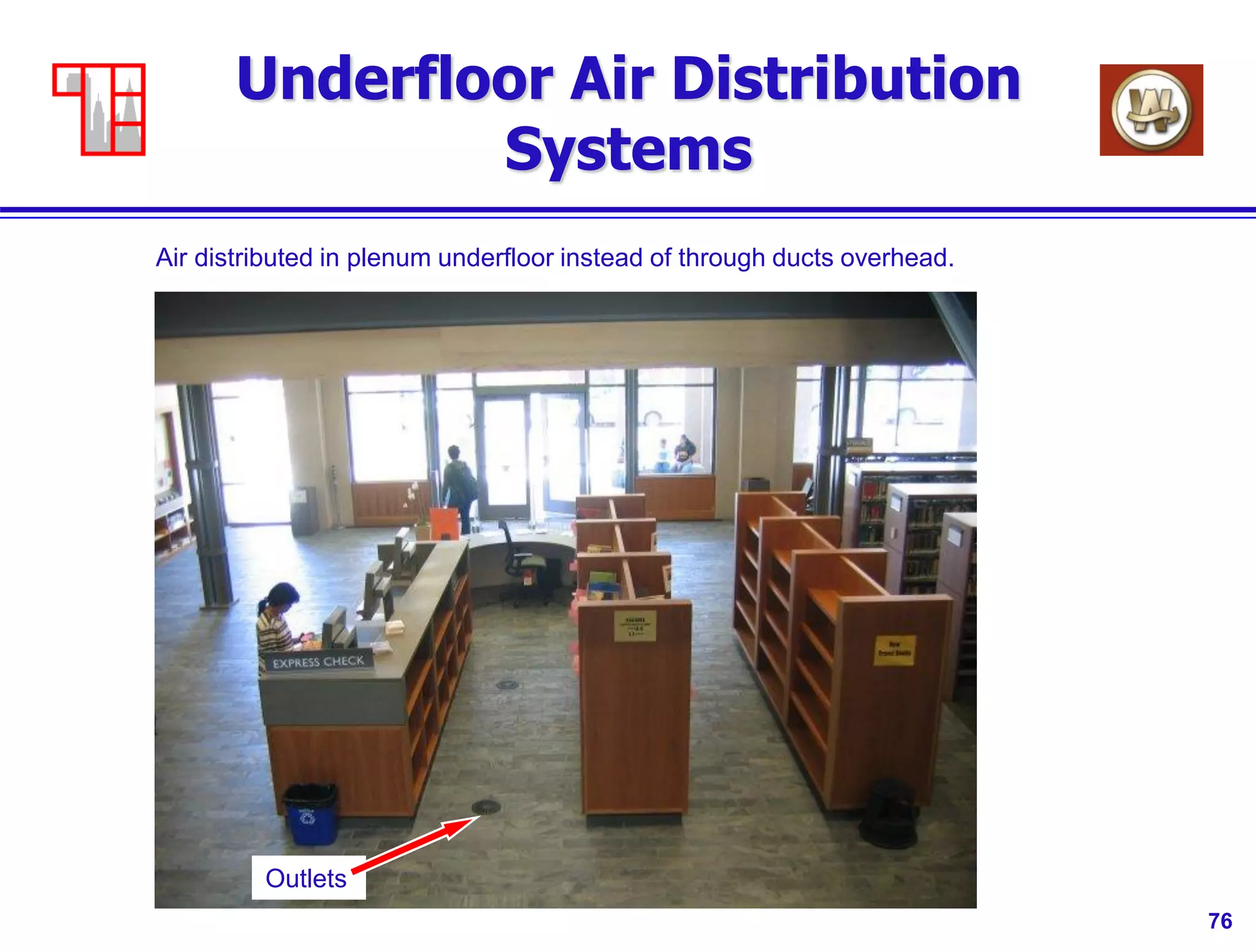

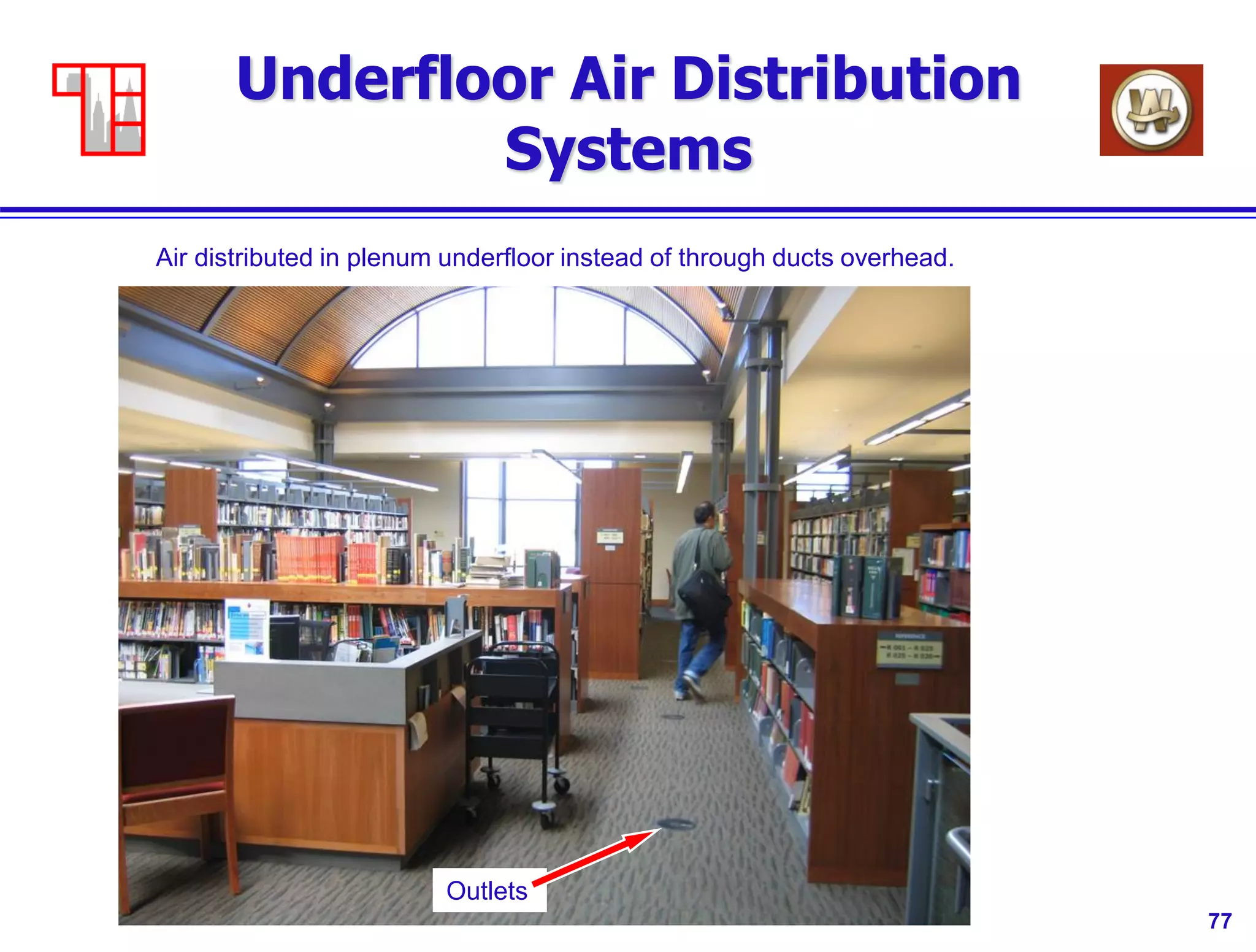

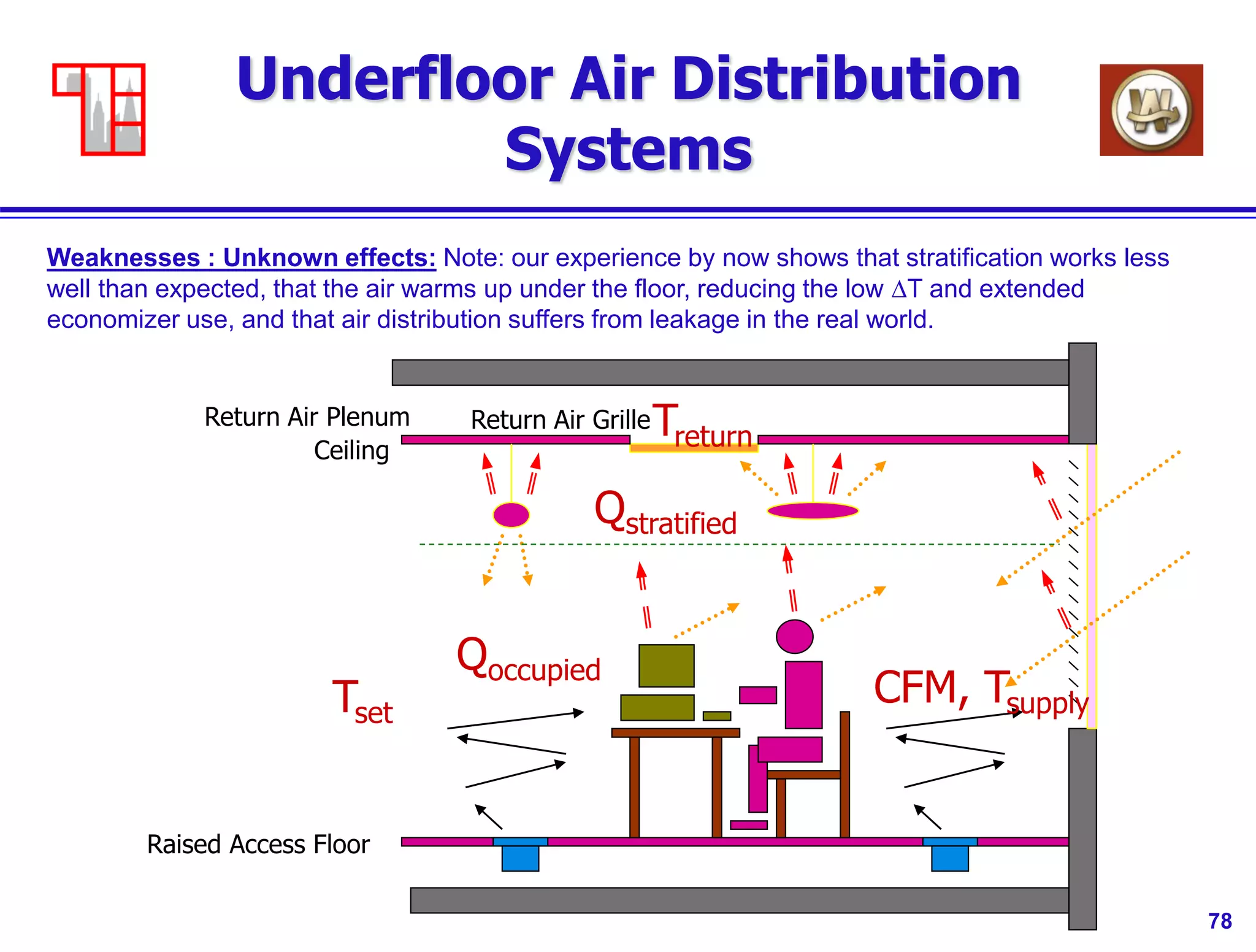

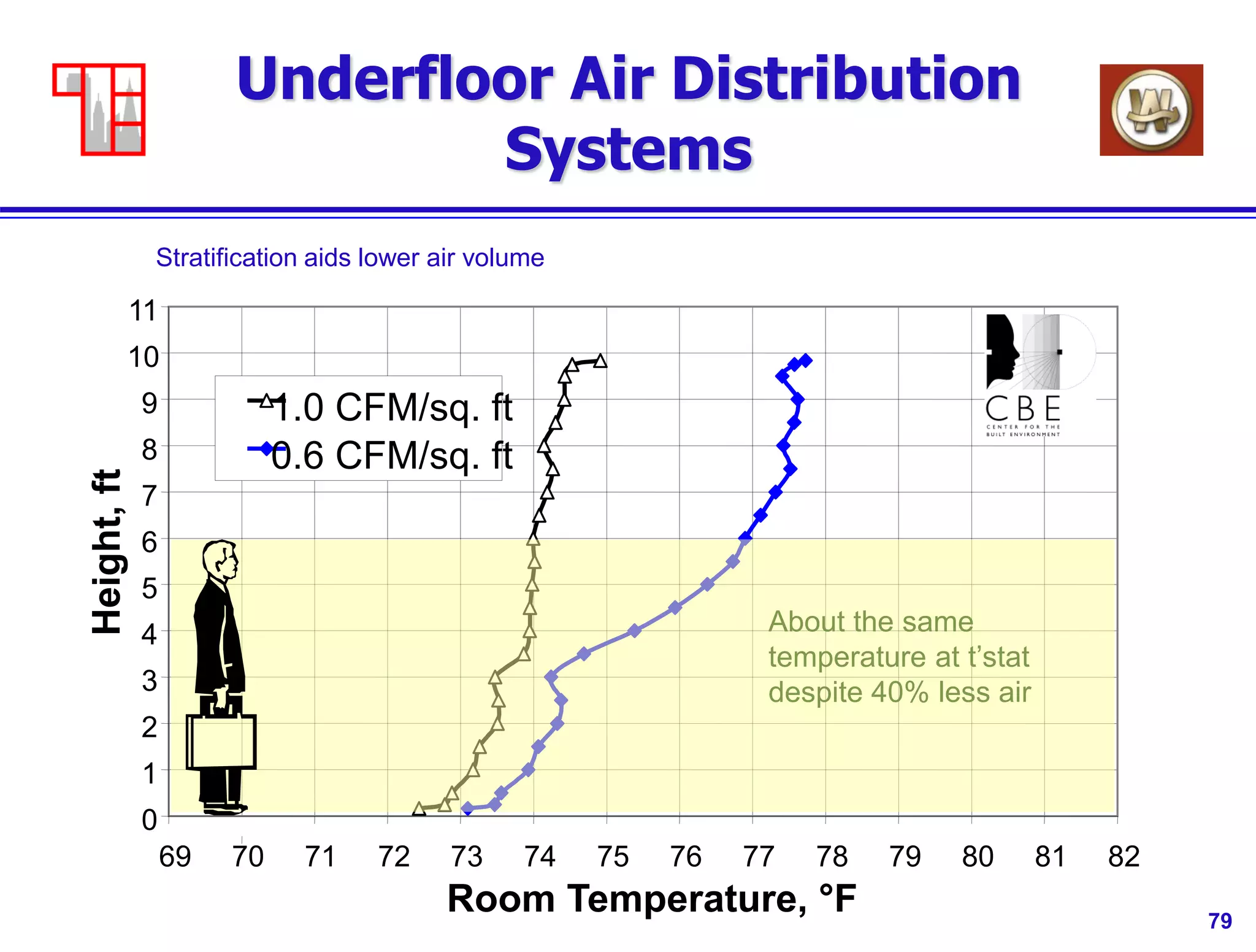

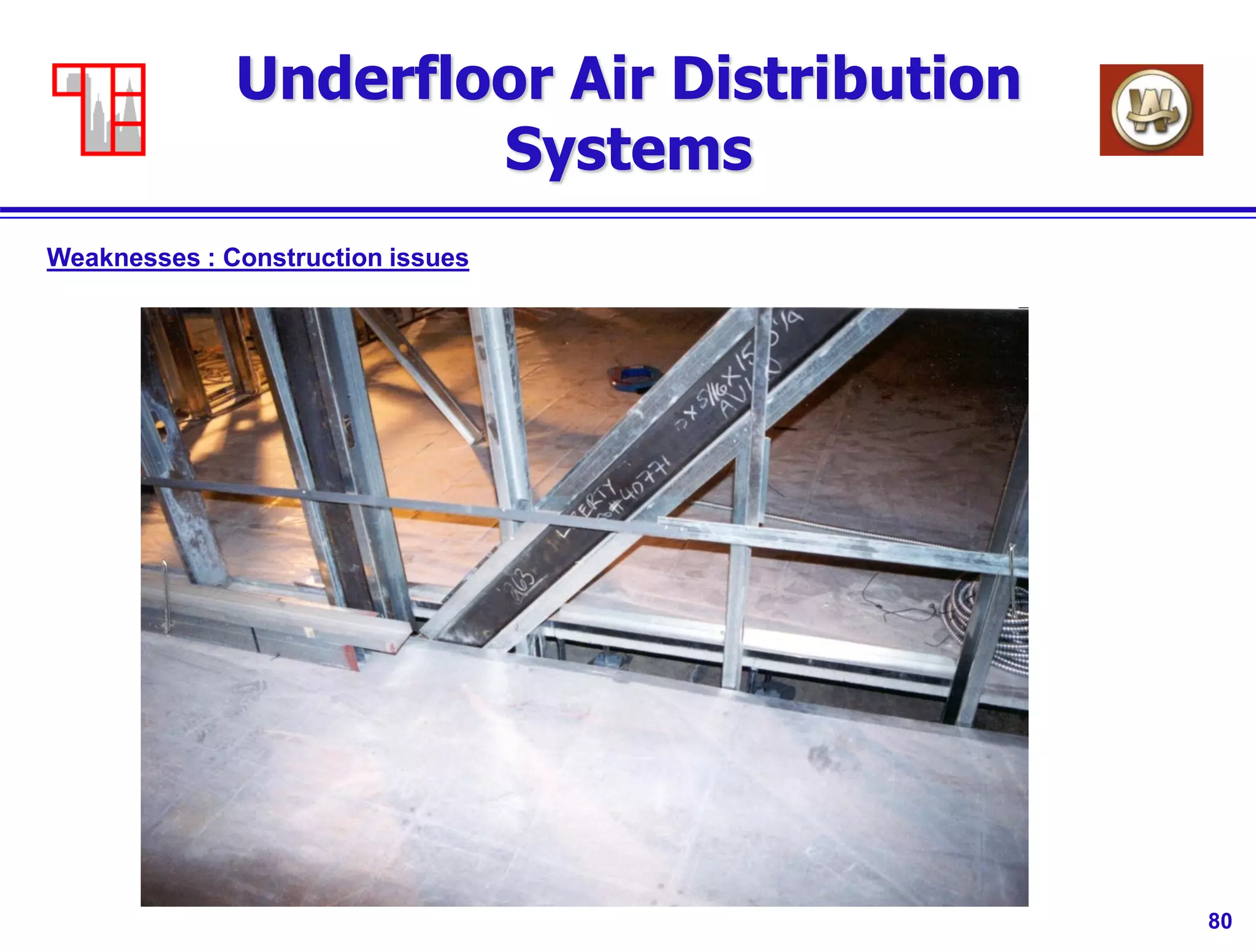

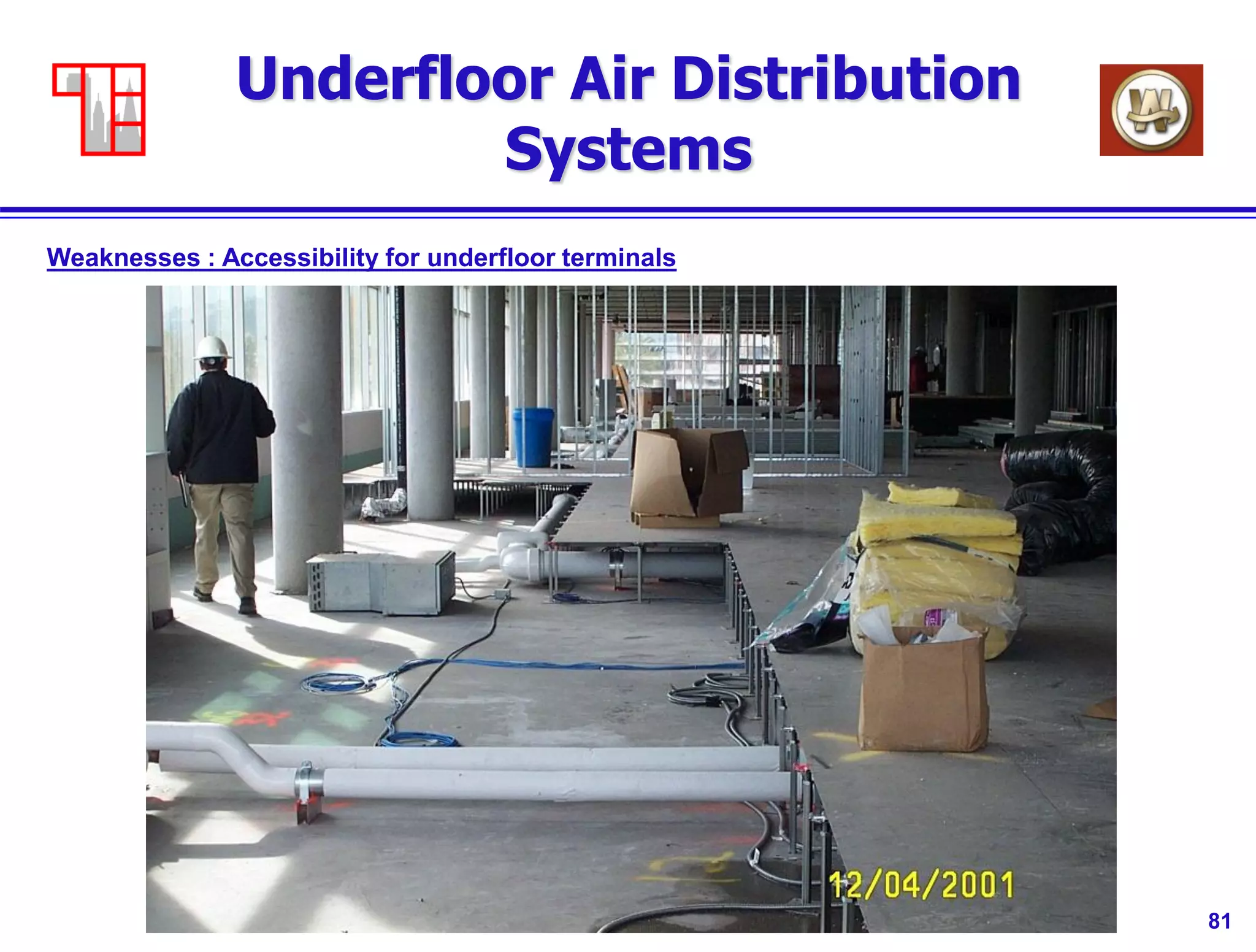

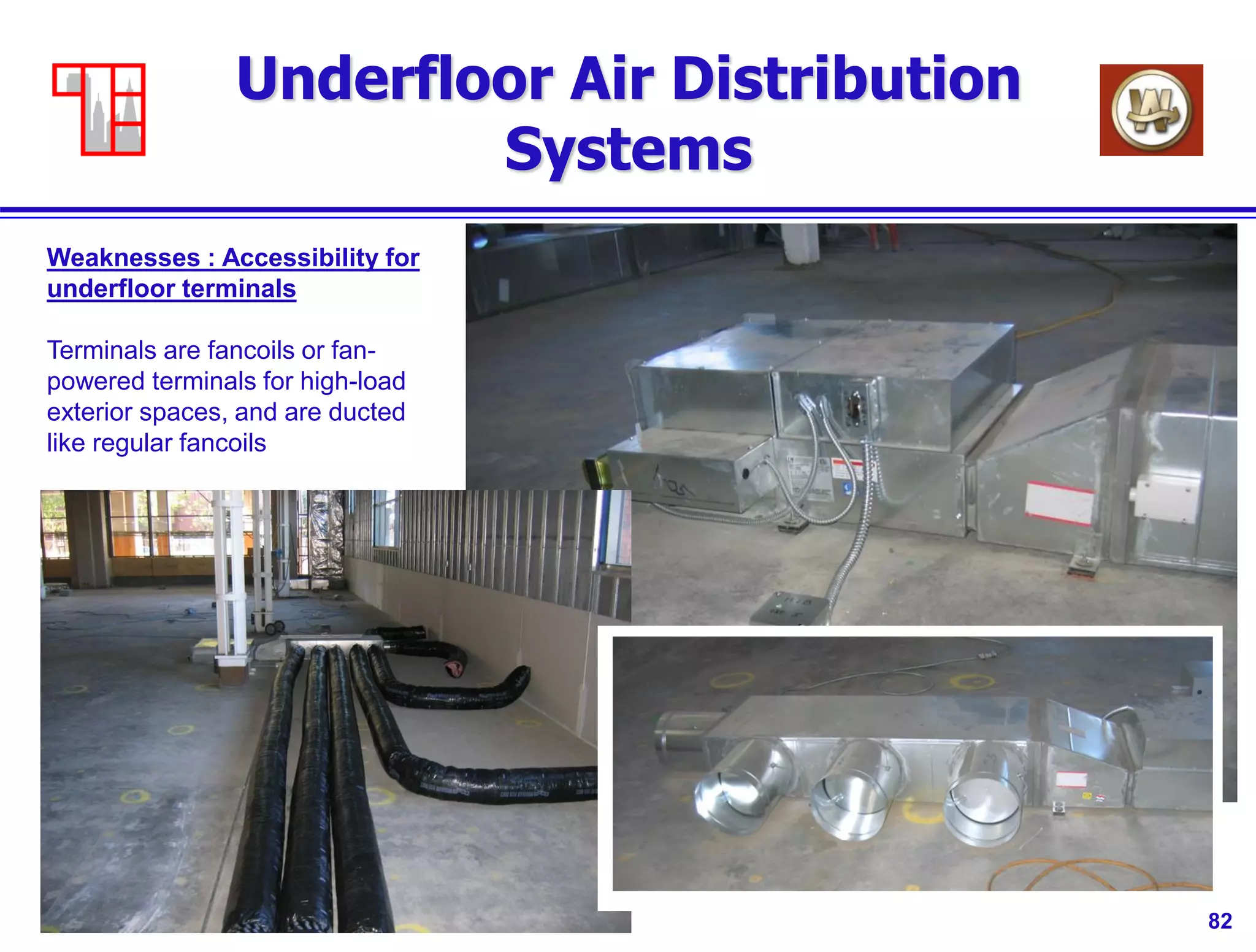

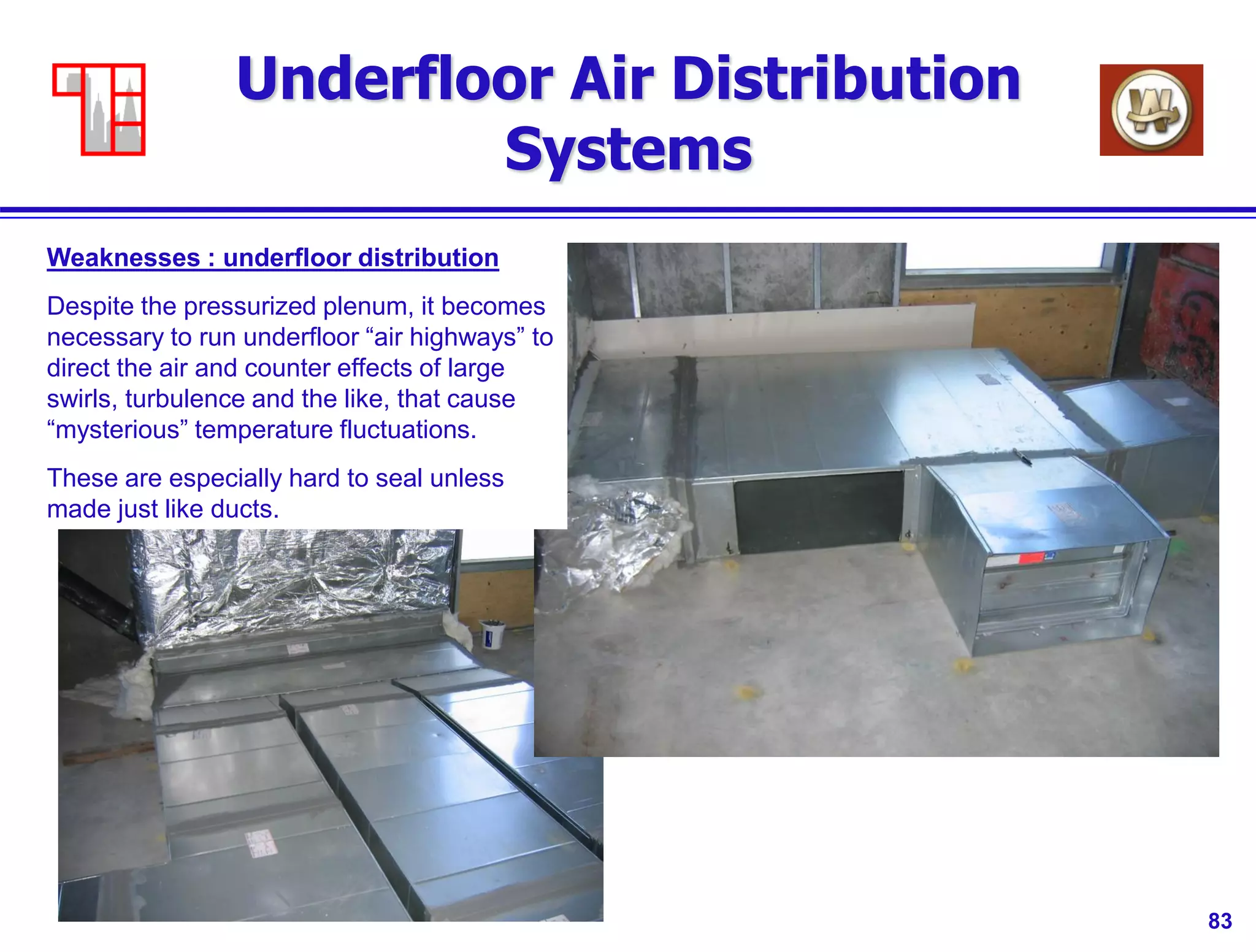

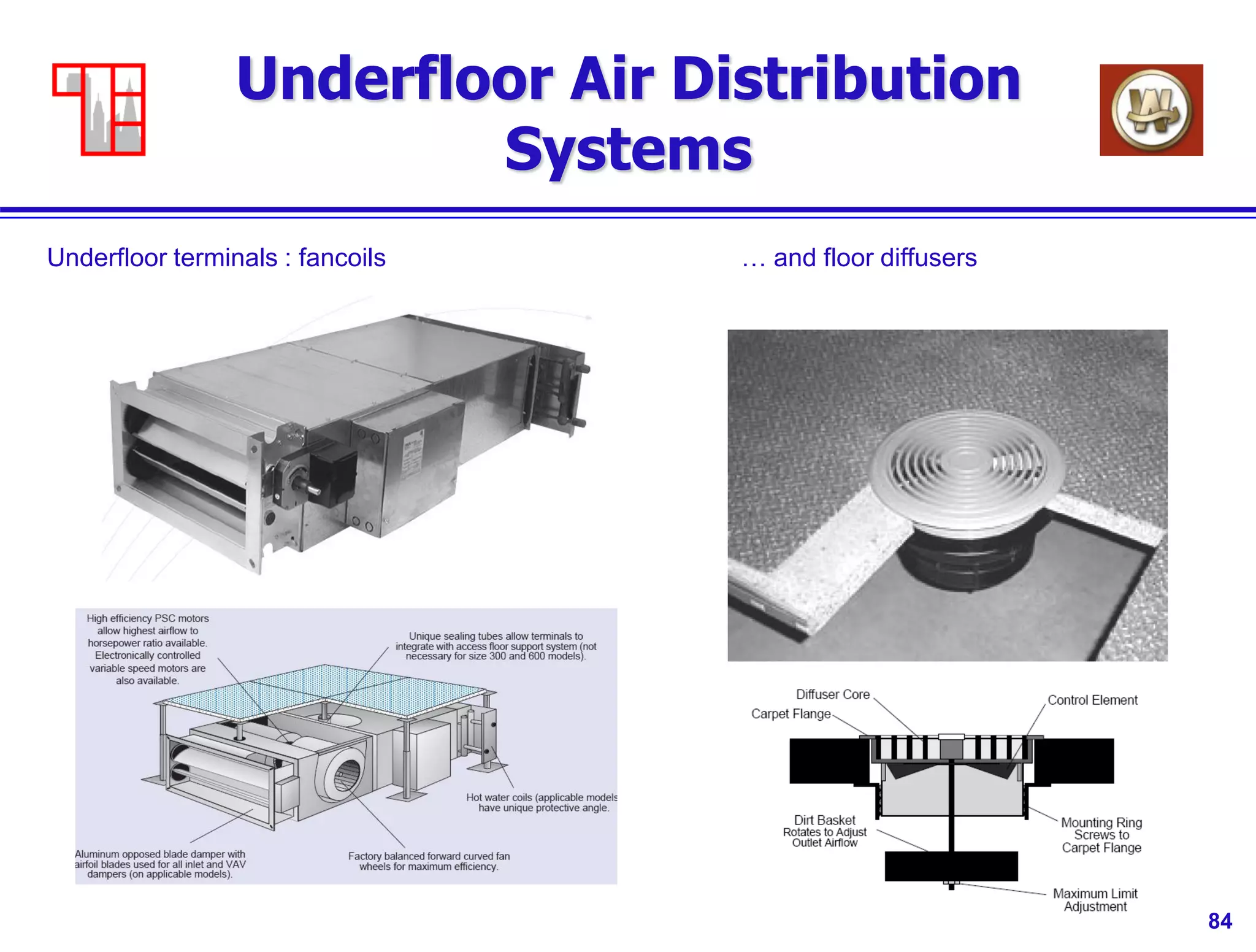

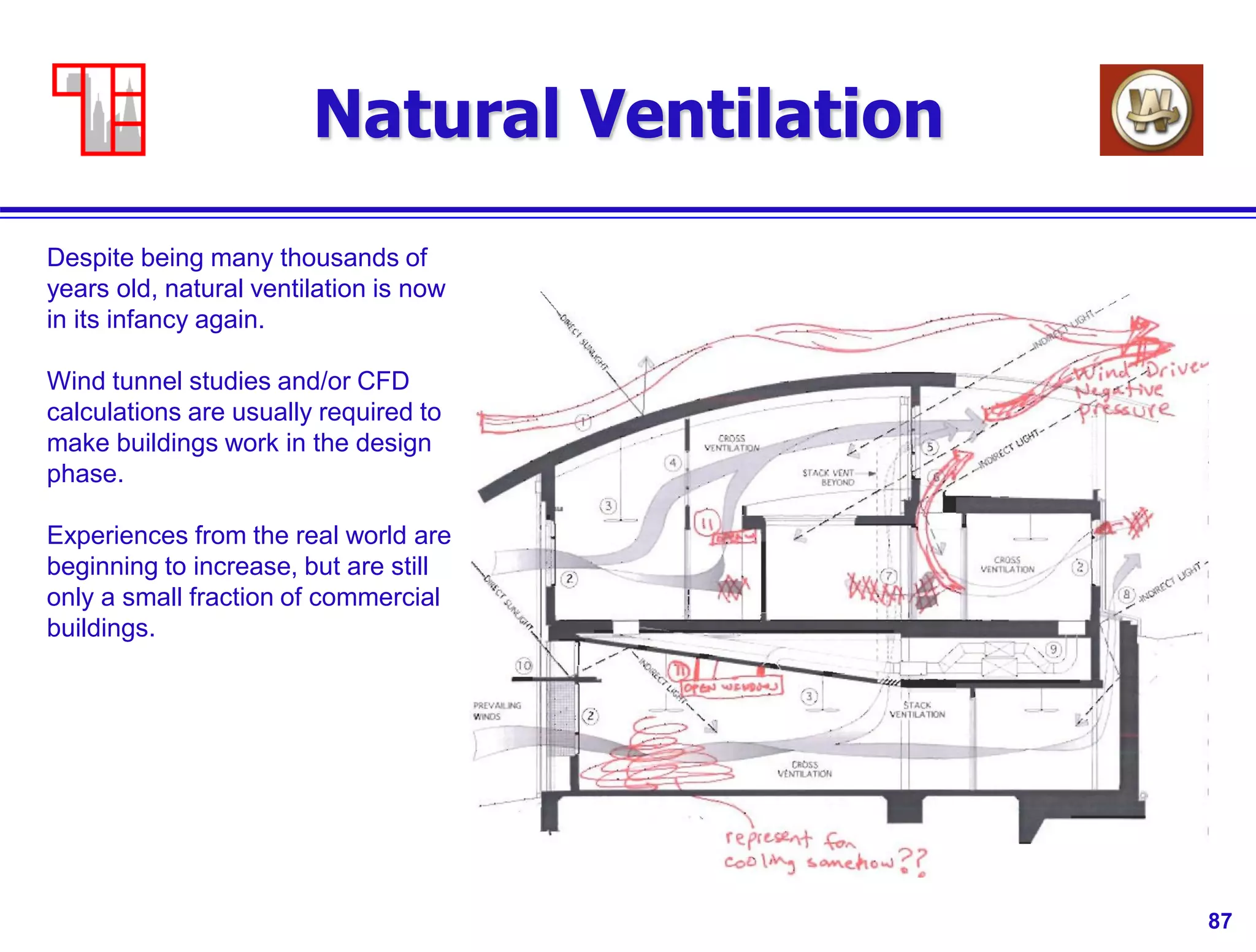

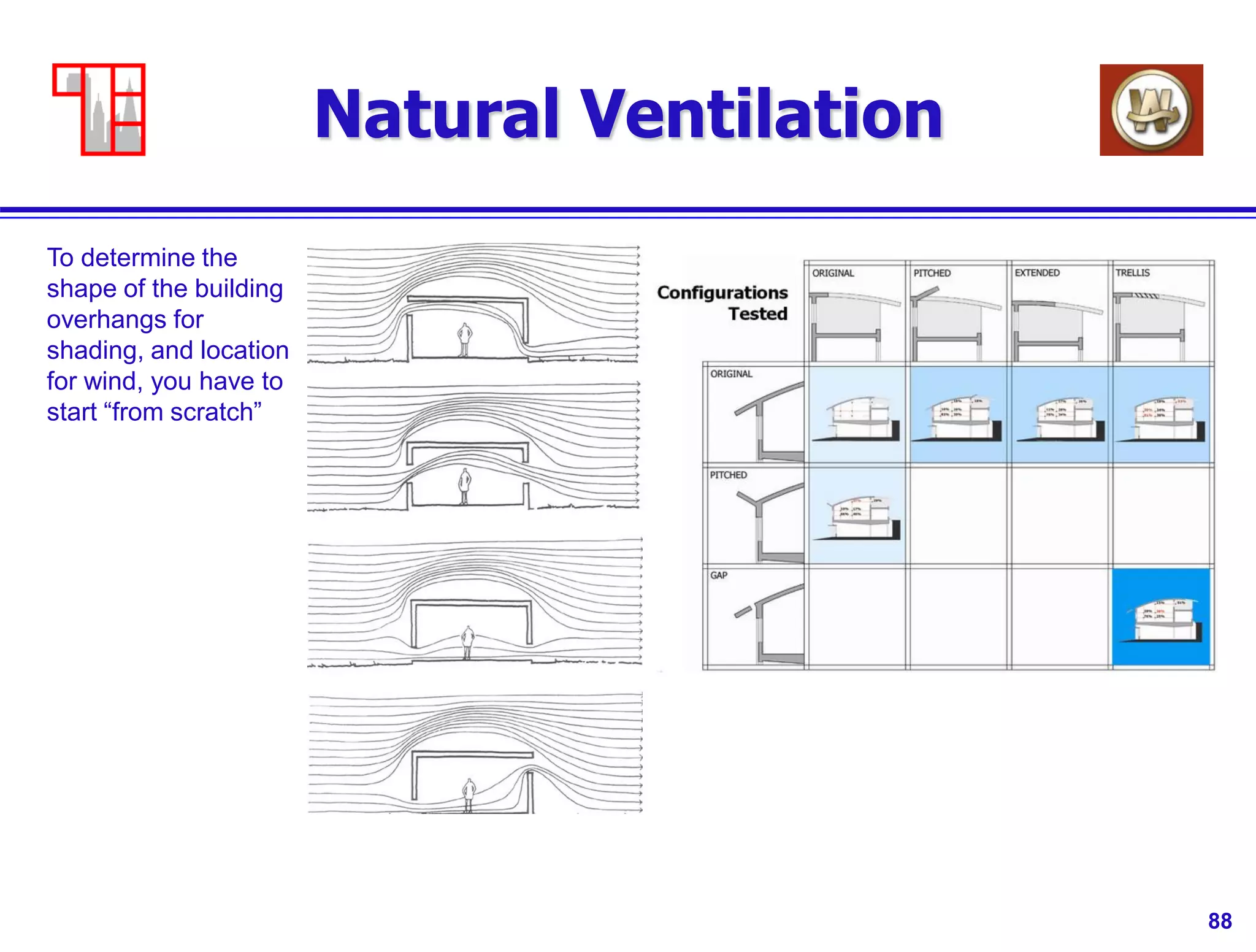

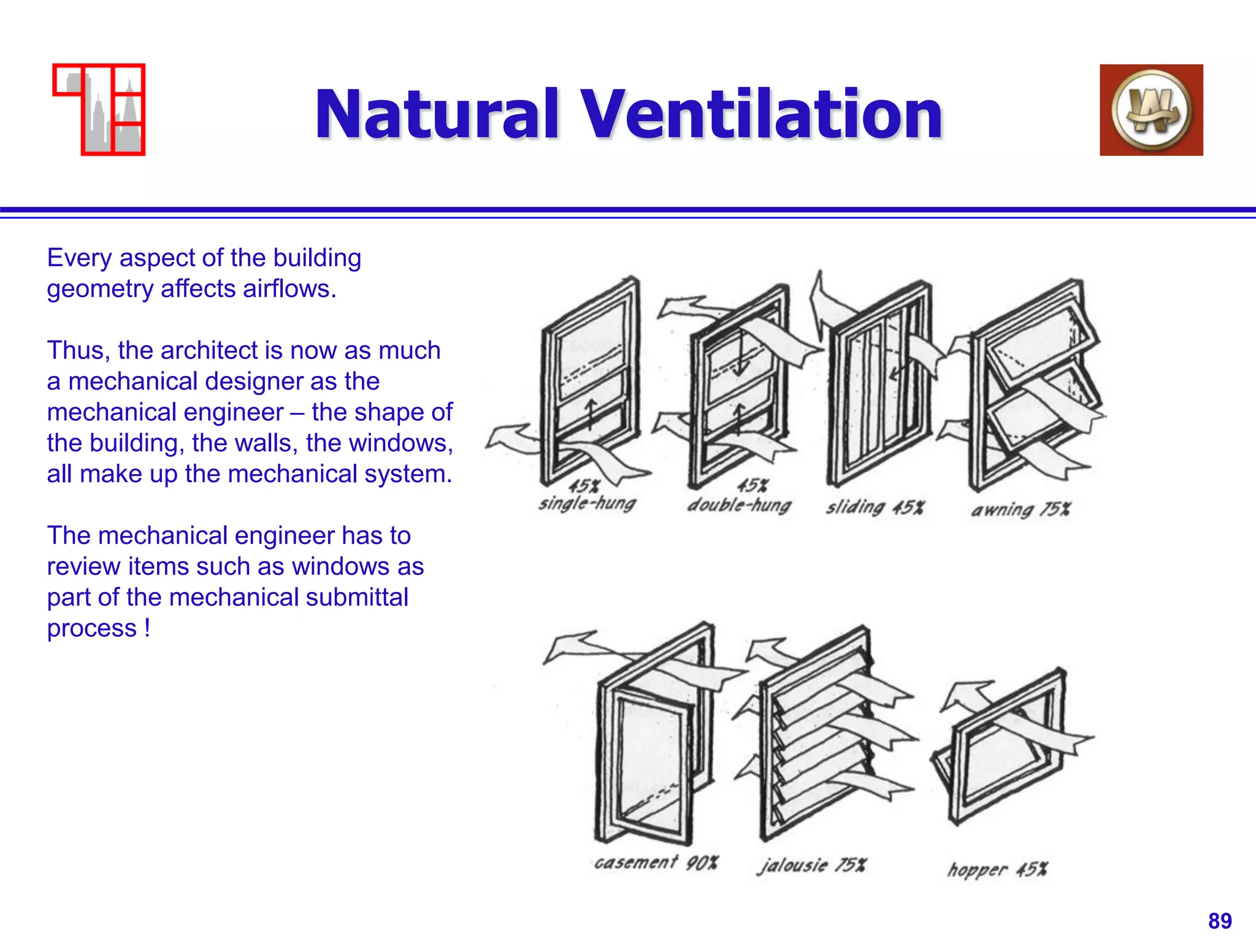

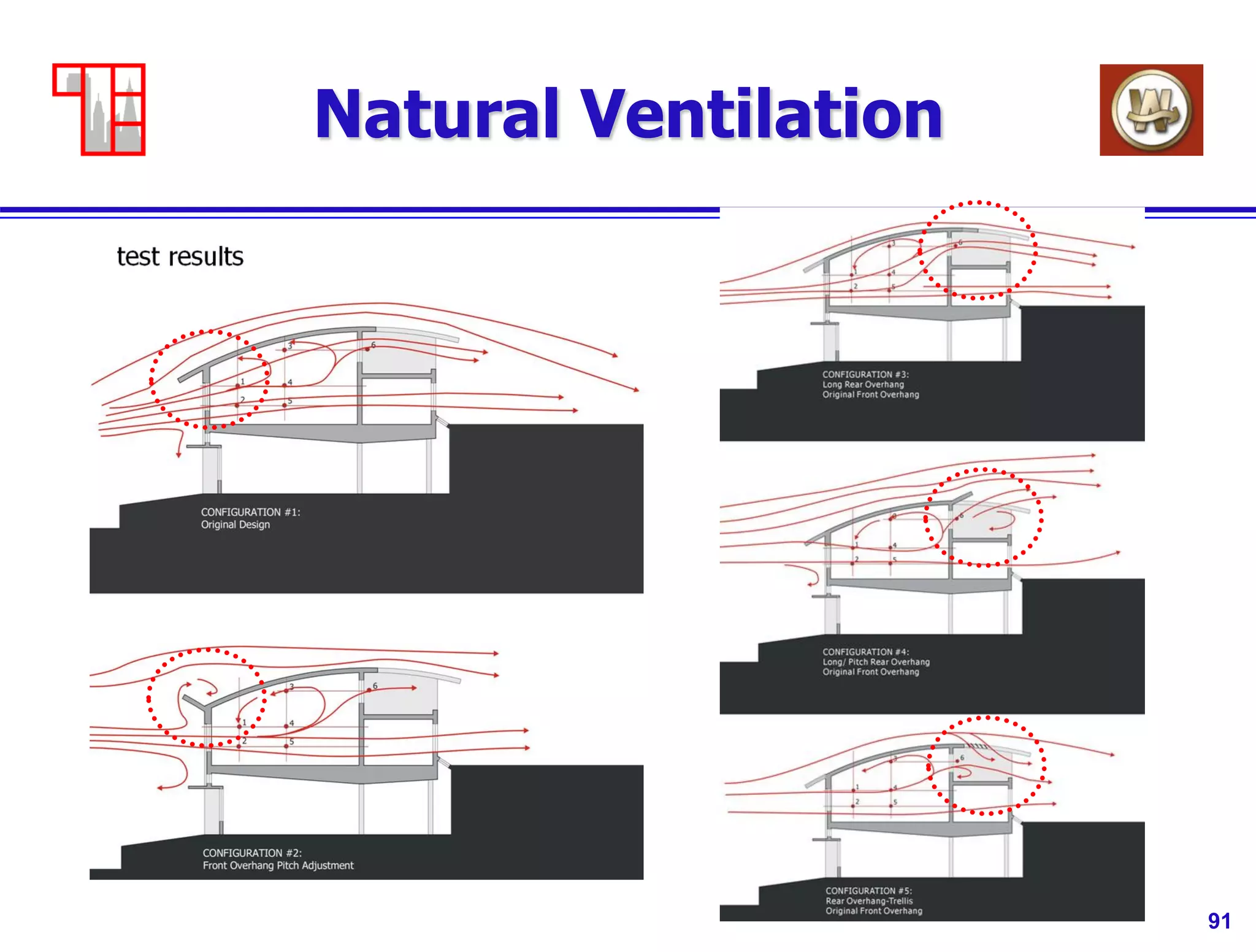

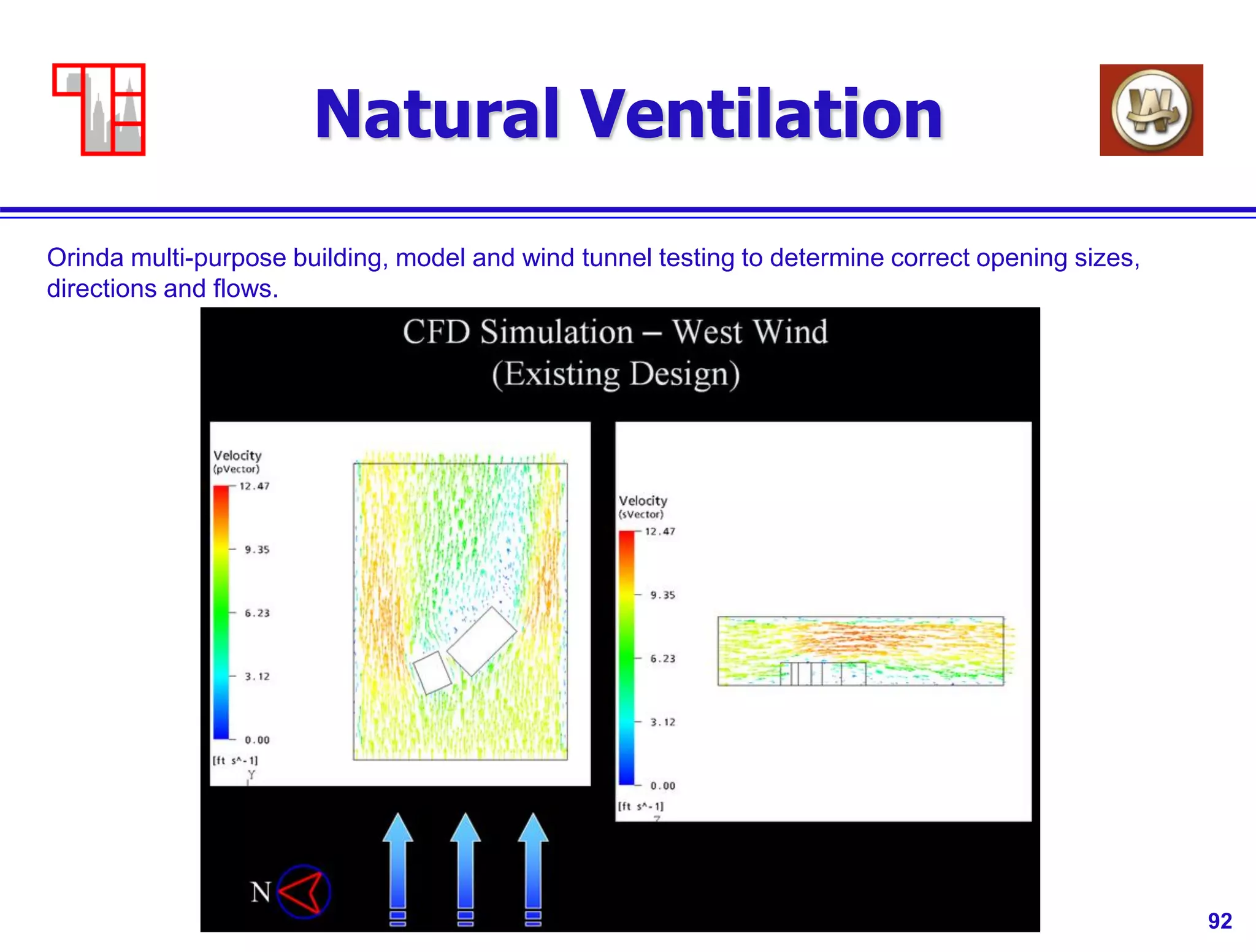

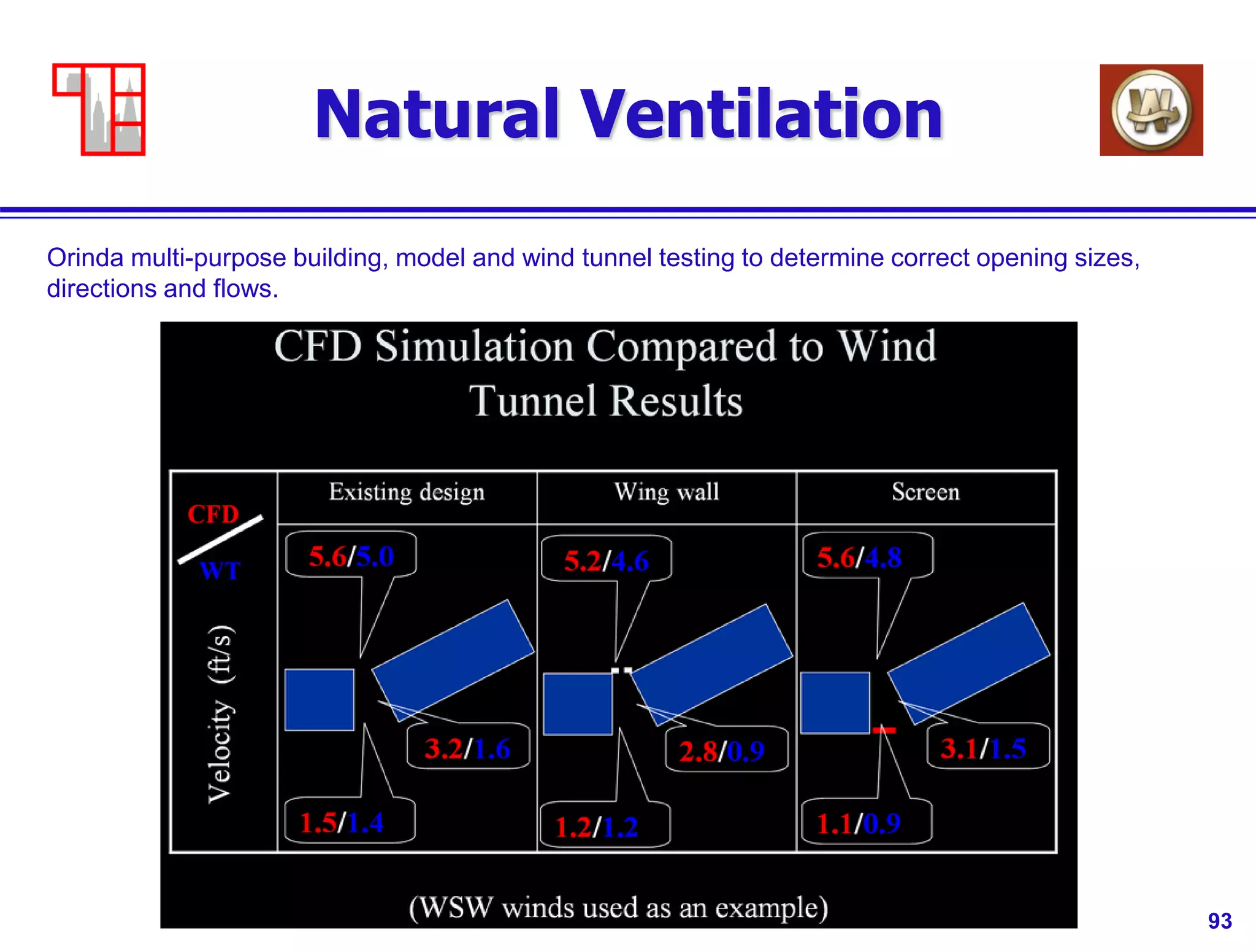

This document provides an overview of HVAC distribution systems for a class on HVAC system design. It discusses various types of distribution systems including single zone, constant volume, VVT, VAV reheat, dual duct, DOAS, displacement, UFAD and natural ventilation. For each type, it highlights reasons for choosing the system and potential limitations. It also outlines the course topics to be covered by three instructors over 10 classes, and provides examples of different distribution system layouts.