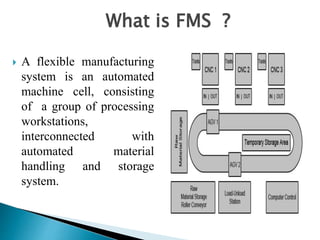

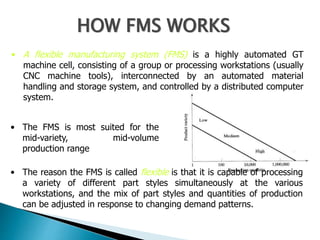

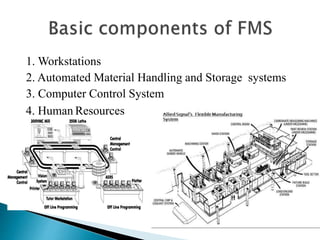

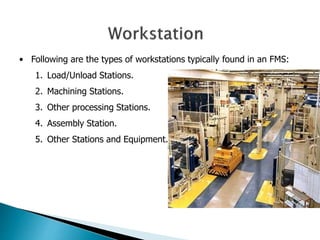

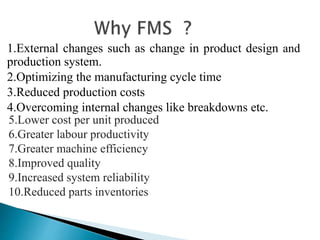

A flexible manufacturing system (FMS) is an automated machine cell consisting of a group of processing workstations like CNC machine tools interconnected by an automated material handling and storage system and controlled by a distributed computer system. FMS allows manufacturers to produce a variety of different part styles simultaneously and adjust production mix in response to changing demand while maintaining good quality and low costs. It transfers workpieces between machining stations using automated equipment like conveyors.

![FLEXIBLE

MANUFACTURING

SYSTEMS (FMS)

BY - SHIVAM JOSHI

[0131ME114]](https://image.slidesharecdn.com/shivam1-140925142741-phpapp01/75/flexible-manufacturing-systems-1-2048.jpg)