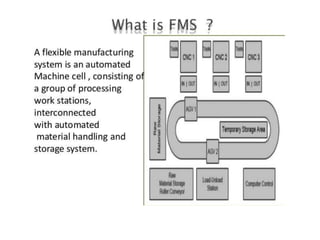

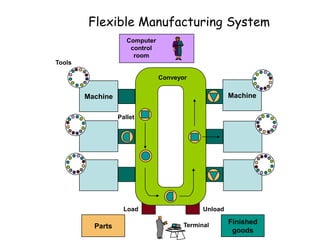

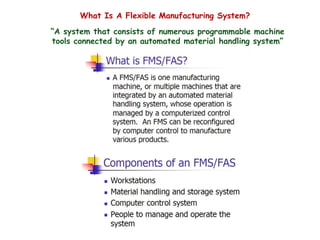

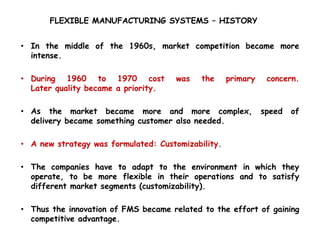

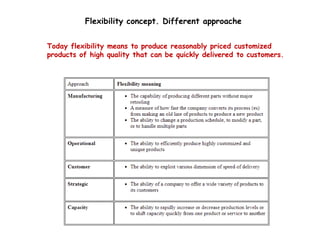

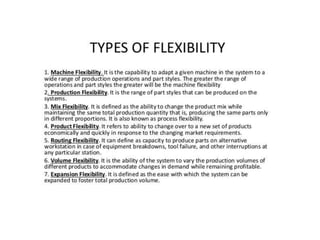

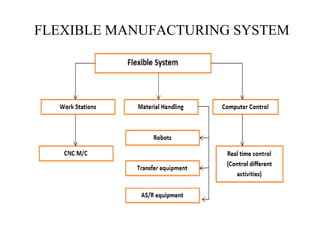

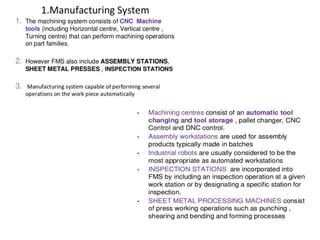

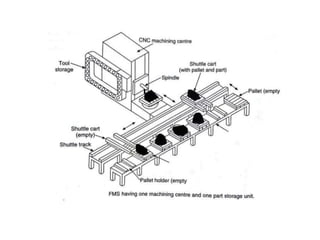

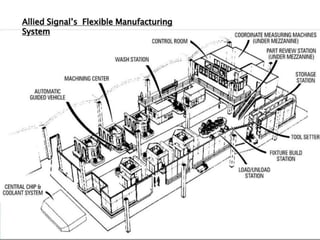

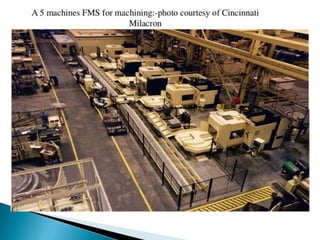

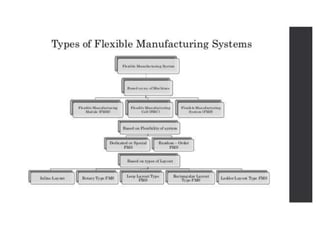

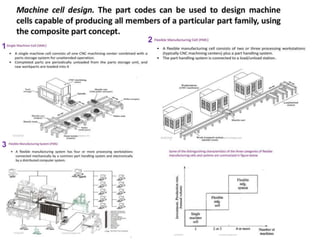

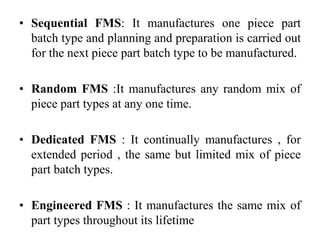

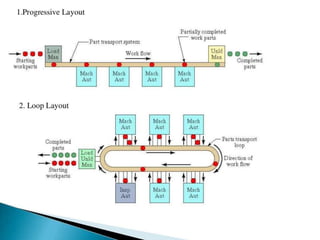

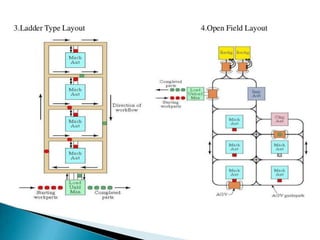

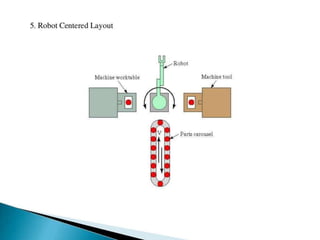

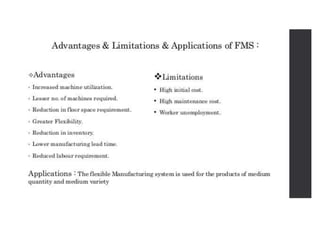

This document discusses flexible manufacturing systems (FMS) over five units. It introduces FMS, including its evolution and basic components. FMS combines computer controlled machine tools with automated material handling to improve manufacturing flexibility. The document then covers group technology, flexible manufacturing cells, FMS software, and provides examples of FMS layouts including progressive, loop, ladder, open field, and robot centered types. The goal of FMS is to efficiently produce variable mixes of parts in lower volumes with reduced setup times and costs.