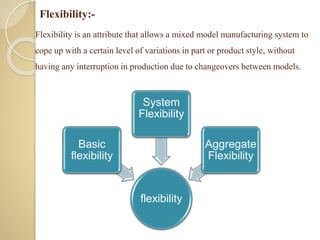

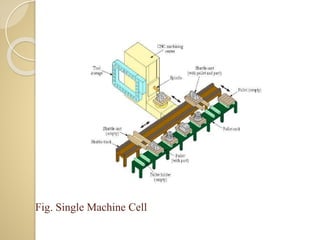

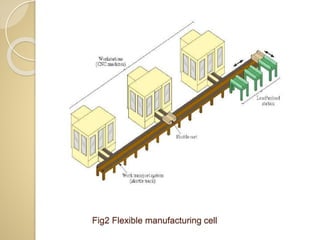

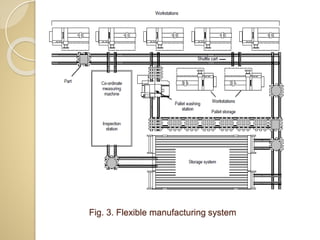

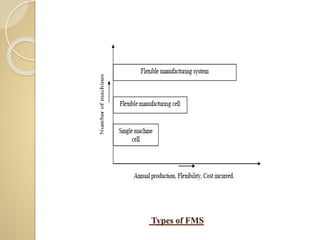

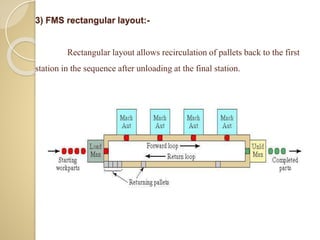

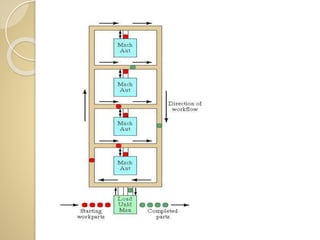

The document discusses flexible manufacturing systems (FMS), highlighting their significance in addressing modern manufacturing challenges such as globalization, cost reduction, and quality improvement. It outlines the various types and layouts of FMS, including single machine cells, flexible manufacturing cells, and complex systems, and emphasizes the importance of flexibility in manufacturing processes. Additionally, it presents the advantages and disadvantages of FMS, as well as its applications in various manufacturing contexts.