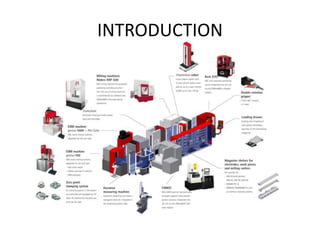

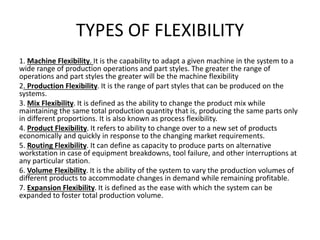

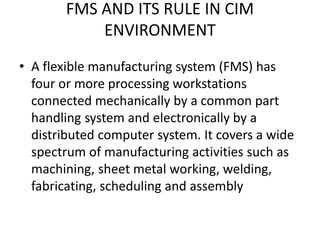

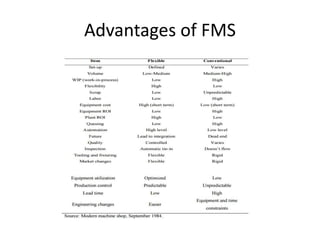

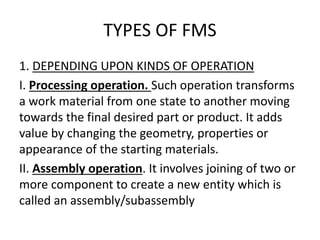

This document discusses flexible manufacturing systems (FMS). It defines FMS as an automated set of numerically controlled machine tools and material handling systems capable of performing a wide range of manufacturing operations with quick tooling and instruction changeovers. The key components of an FMS are described as numerical control machine tools, work holding and tooling, material handling equipment, inspection equipment, and other ancillary systems. FMS provides several types of flexibility including machine, production, mix, product, routing, volume, and expansion flexibility. The document also outlines the physical and control subsystems that make up an FMS.