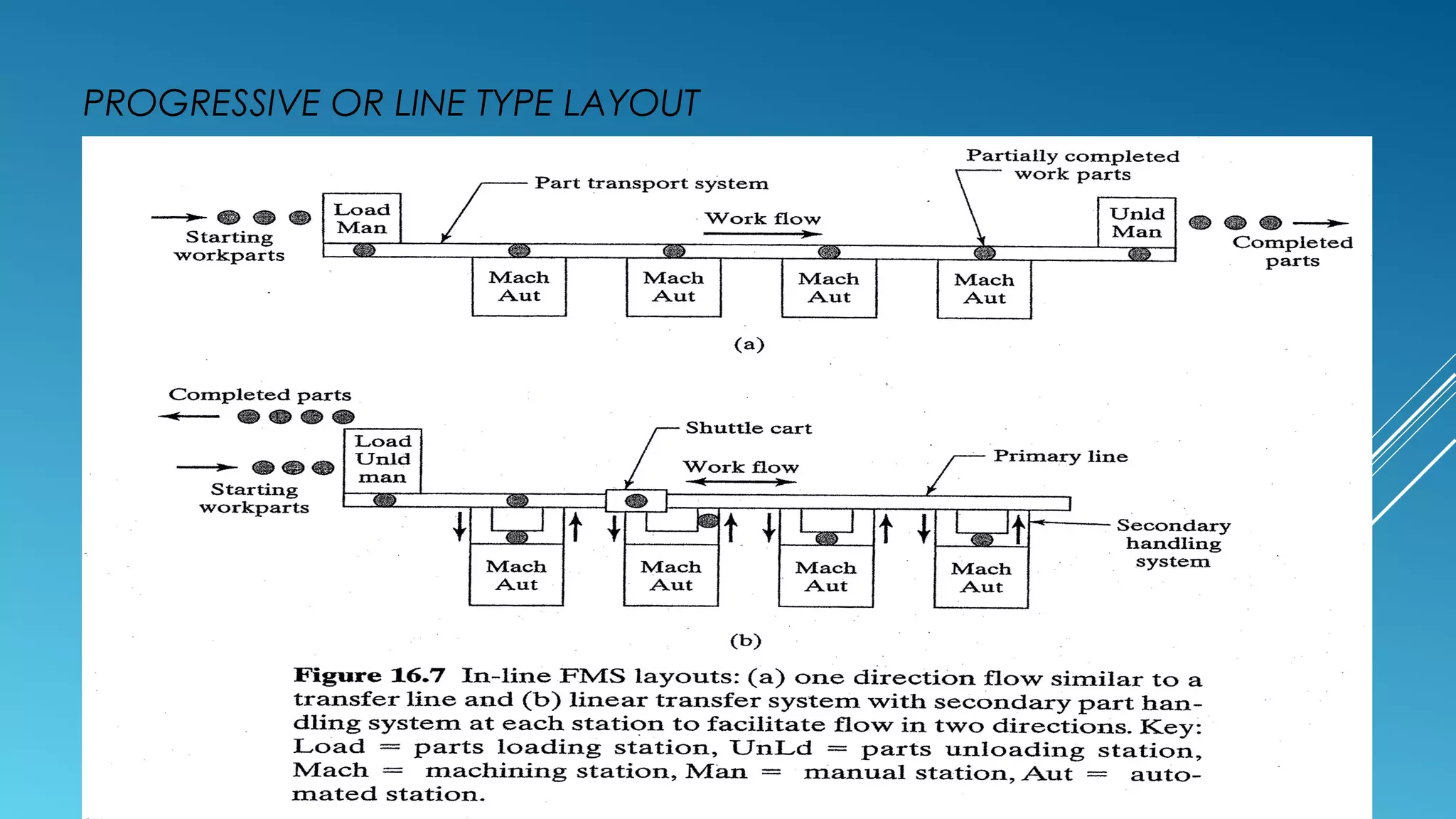

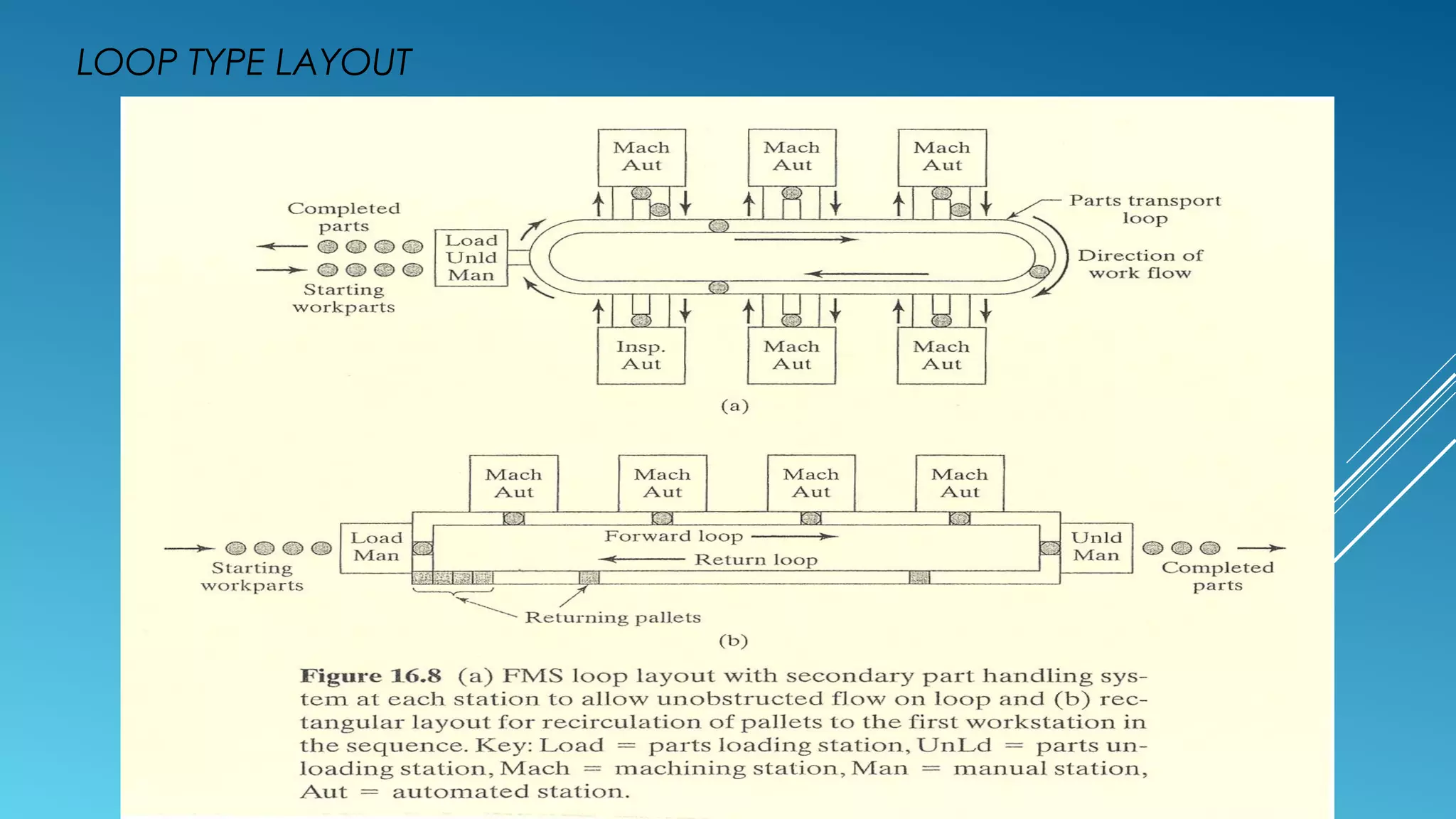

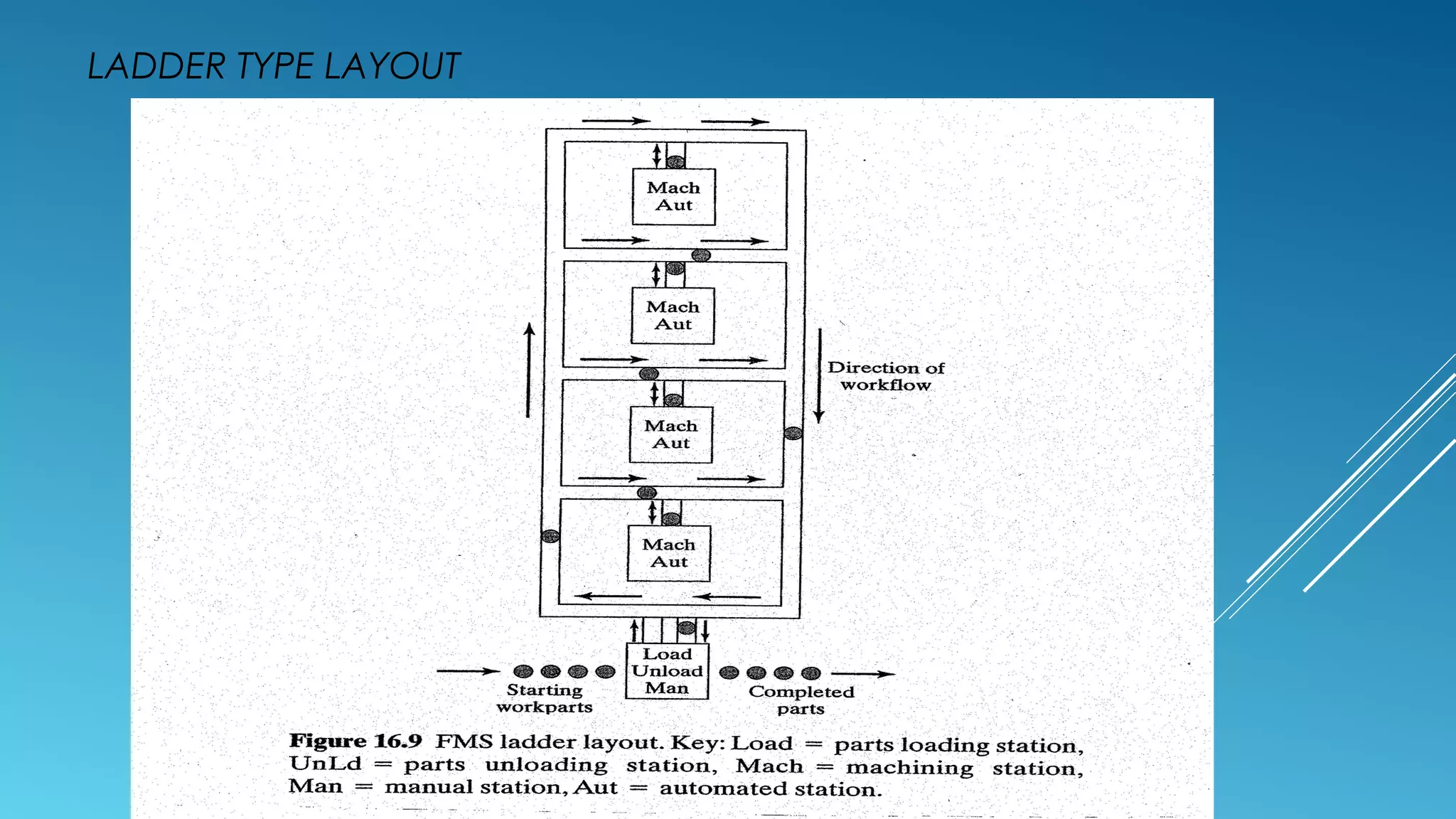

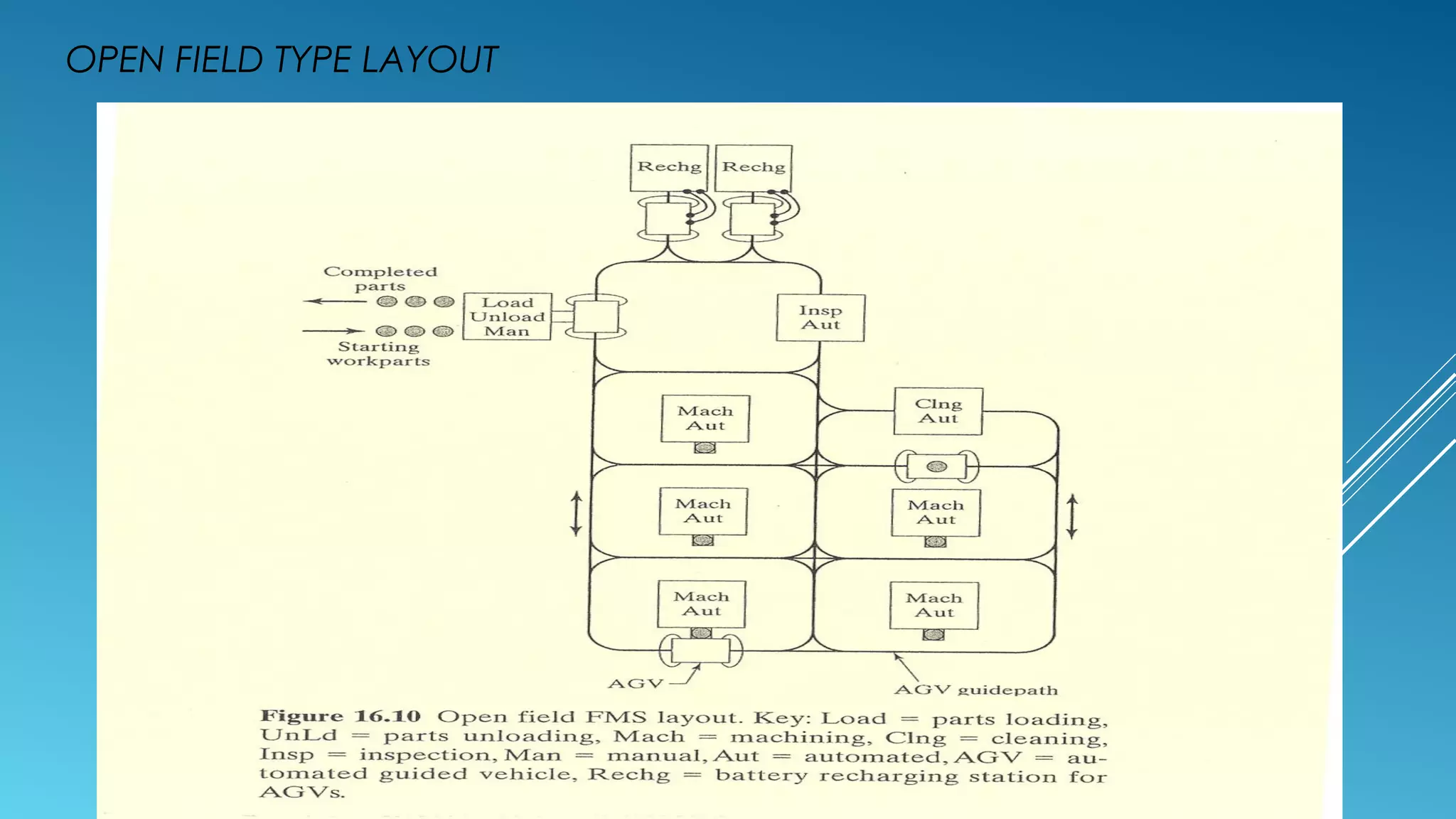

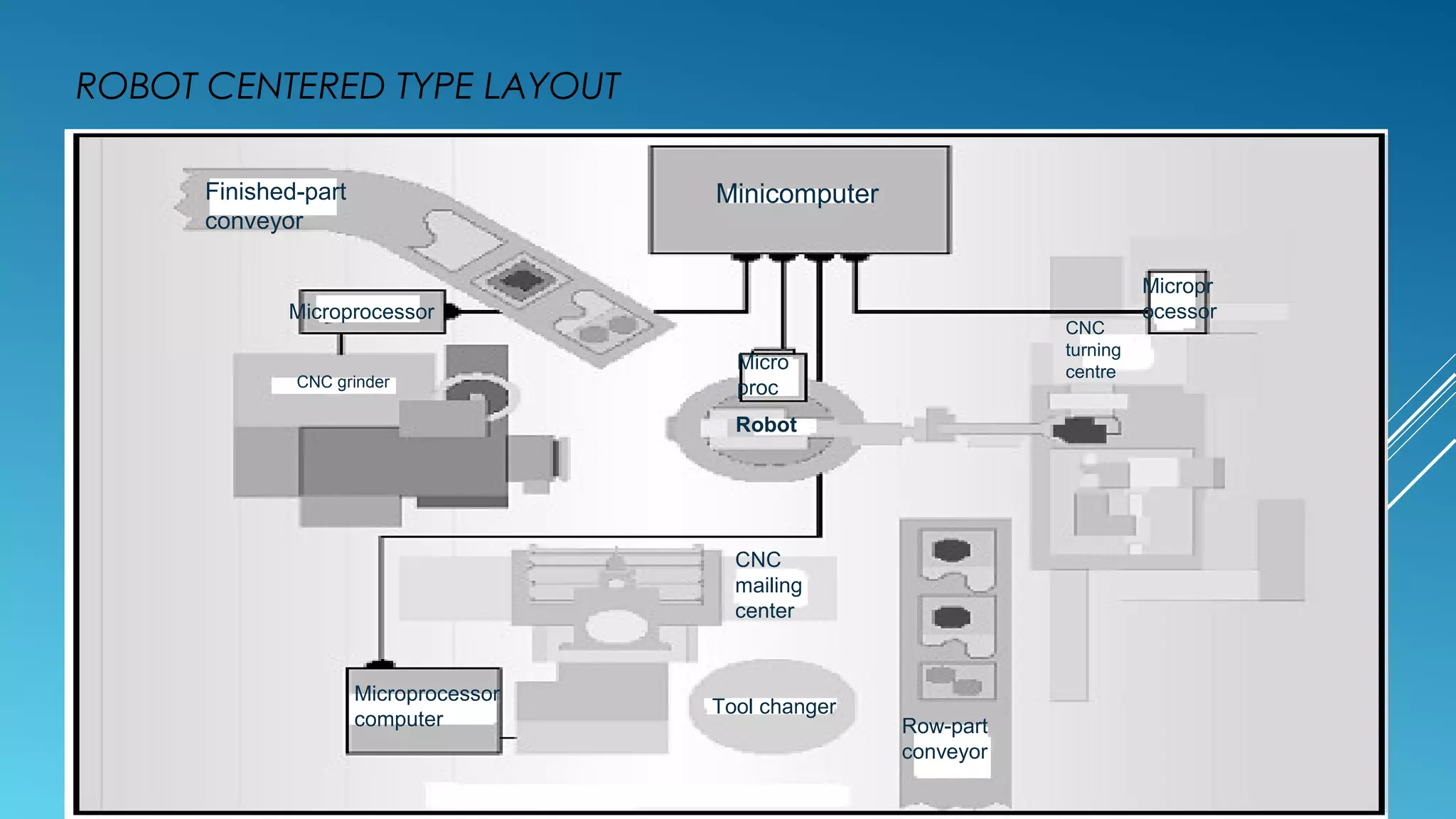

This document discusses different layout configurations for flexible manufacturing systems (FMS). It describes five types of FMS layouts: progressive or line type, loop type, ladder type, open field type, and robot centered type. For each type, it provides a brief explanation of the layout and flow of parts. It also lists some factors that influence the selection of an FMS layout, such as availability of materials and labor, transportation infrastructure, and local business conditions.