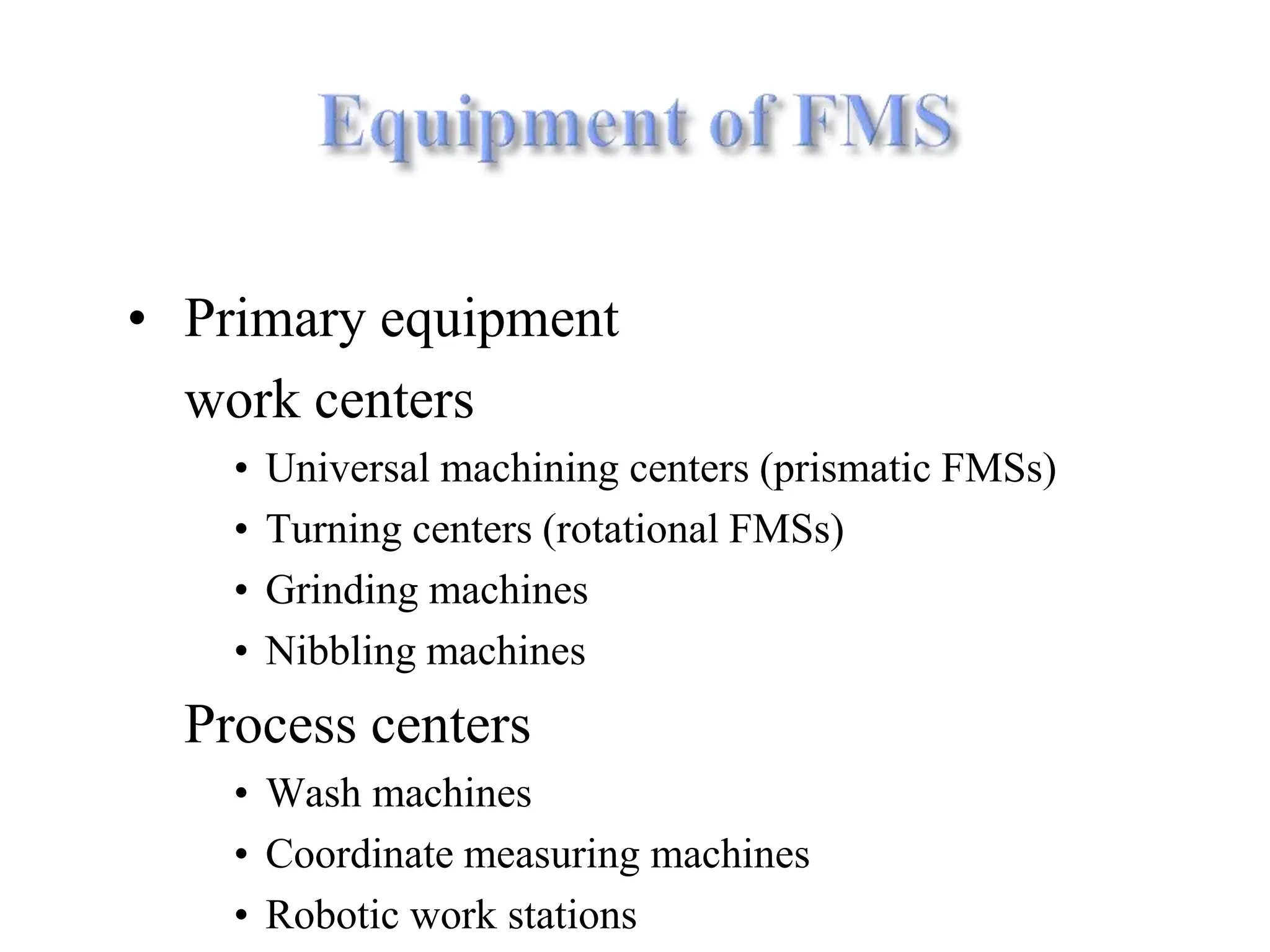

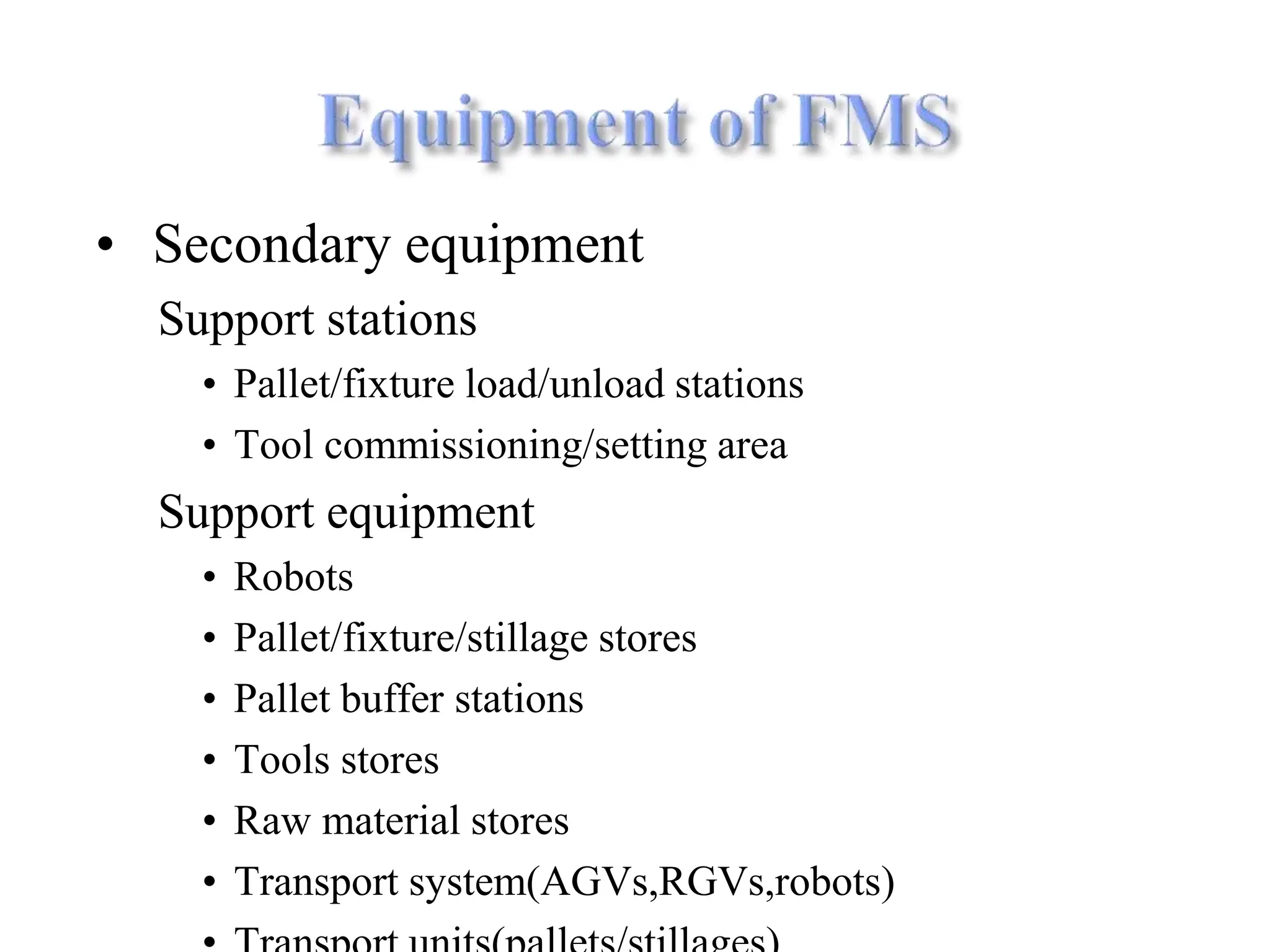

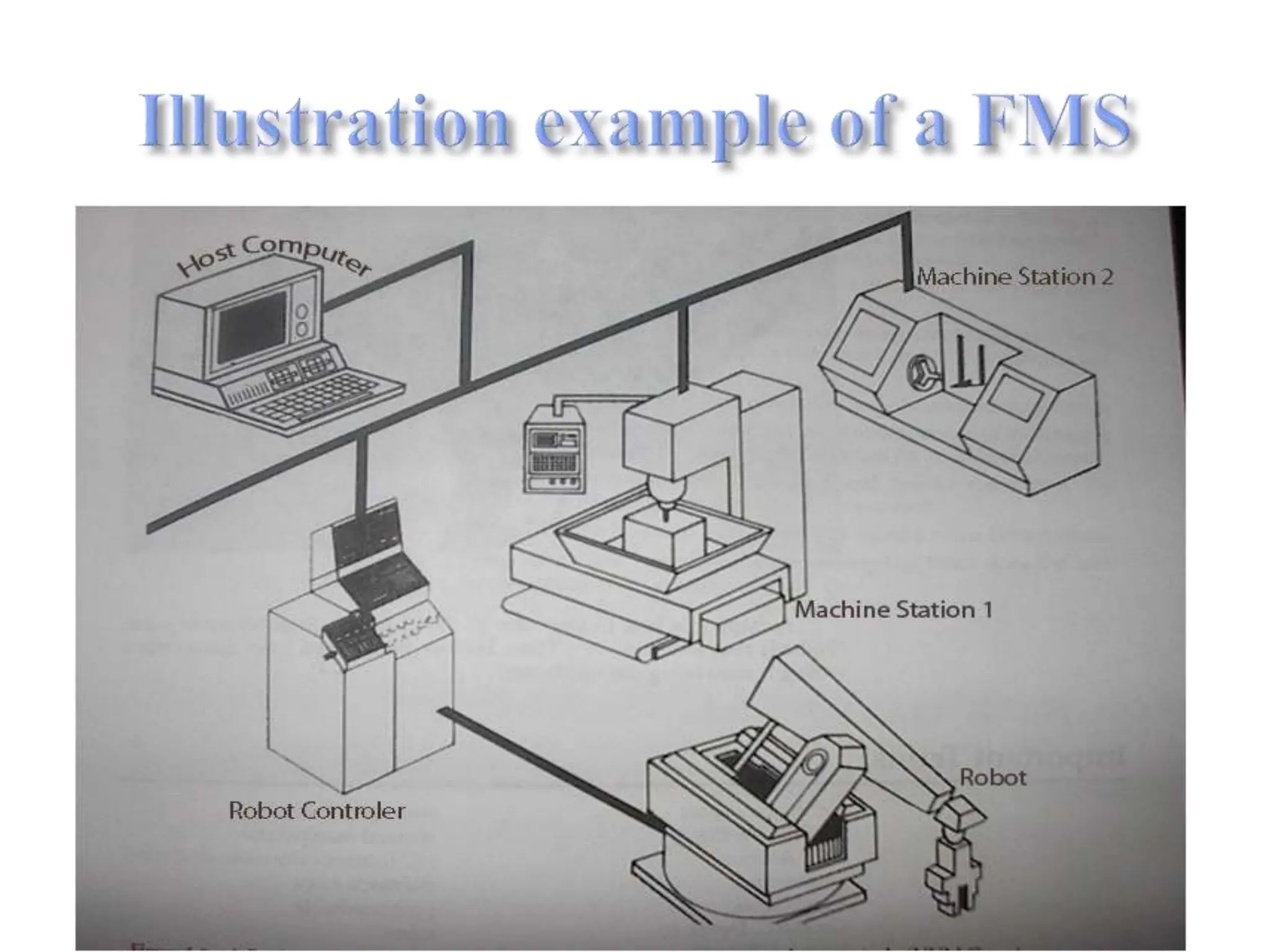

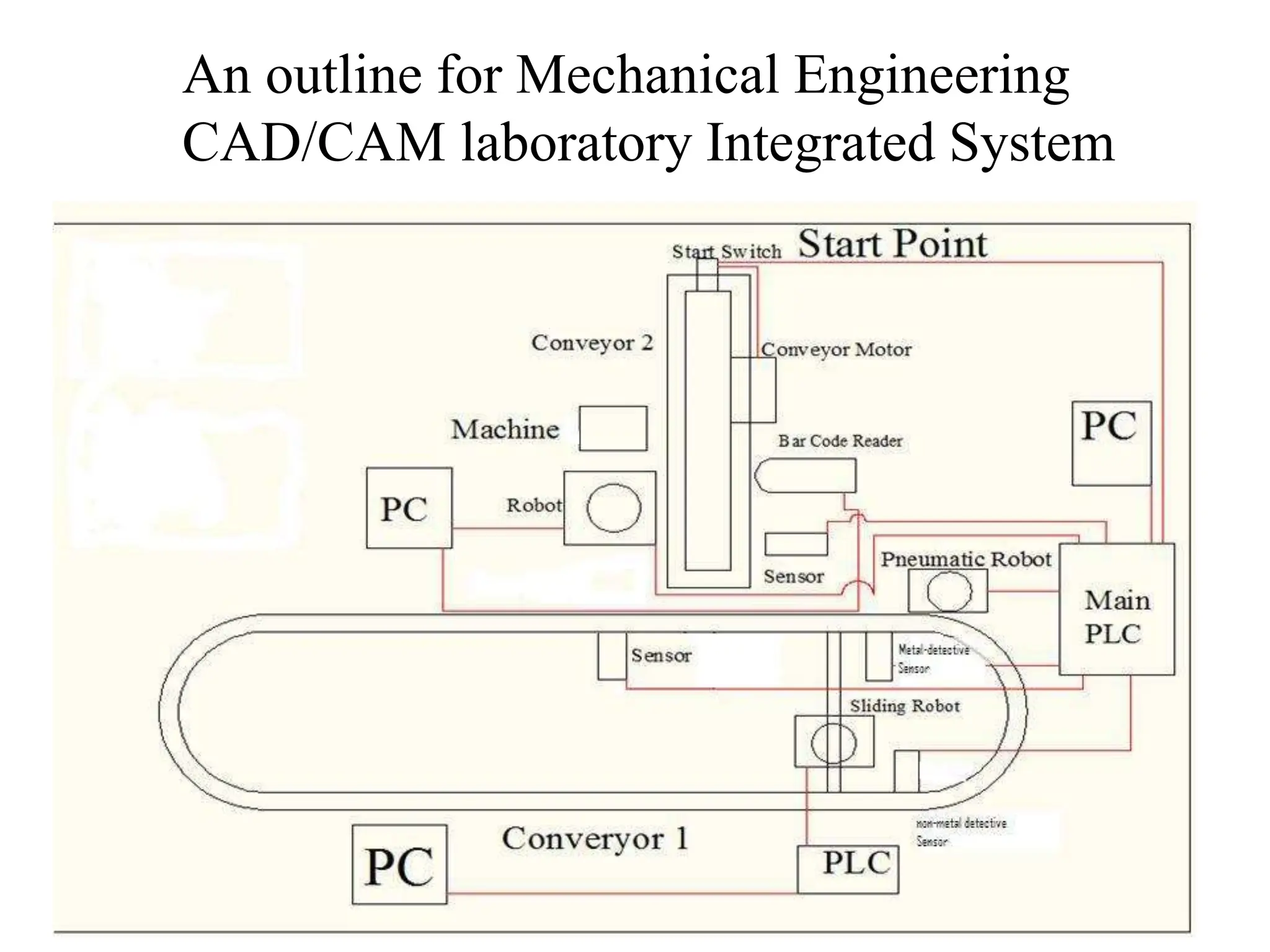

A flexible manufacturing system (FMS) consists of numerically controlled machine tools and automated material handling equipment controlled by a central computer. An FMS allows for flexible production of many part types in any sequence using automated tool changing and material handling. Key components include machines, automated material handling systems, and a central controller. FMS aims to improve efficiency, reduce costs, and increase flexibility over traditional manufacturing methods.