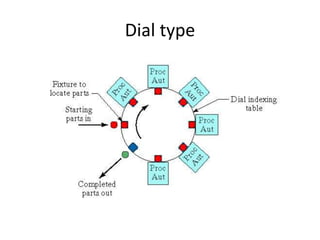

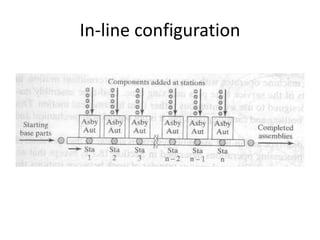

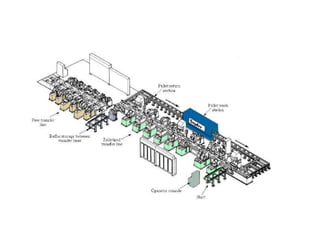

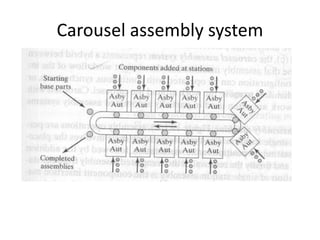

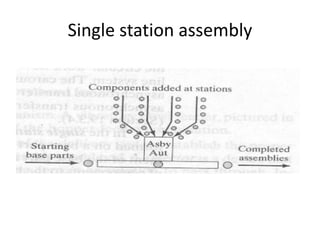

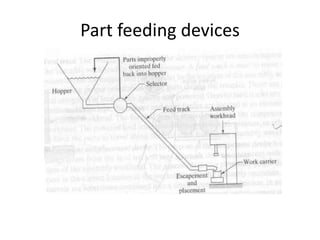

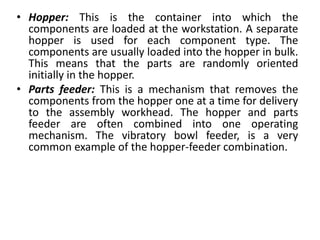

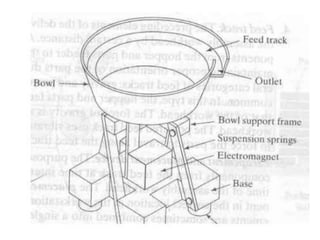

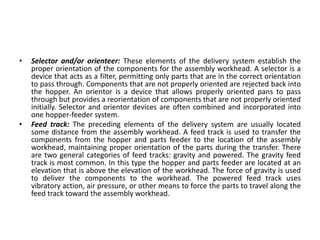

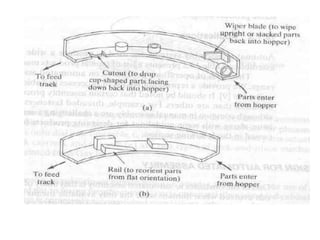

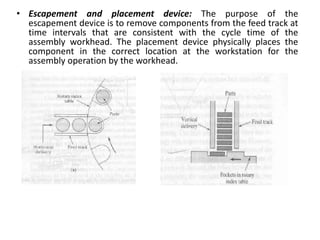

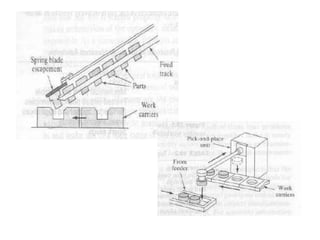

The document discusses automated assembly systems. It describes how automated assembly involves using mechanized devices to join parts together on an assembly line. There are different types of automated assembly systems like dial-type, in-line, carousel, and single-station machines. The document also discusses factors to consider for automated assembly like product demand, design, and component size. It outlines principles for designing products for automated assembly and describes common part feeding devices used like hoppers, feeders, tracks, and escapement/placement mechanisms.