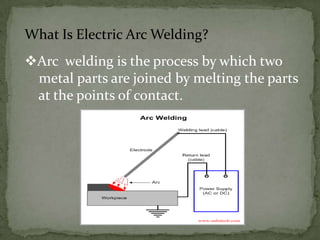

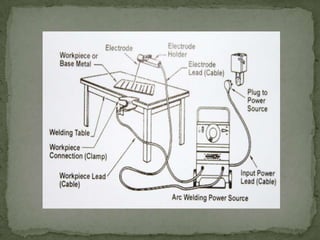

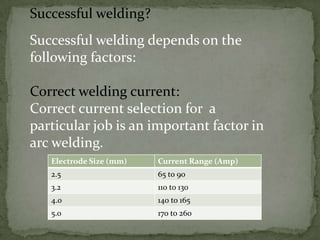

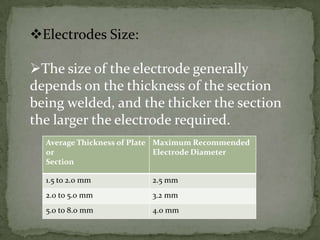

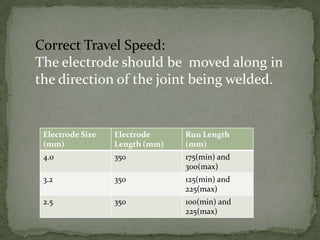

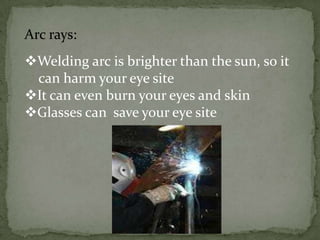

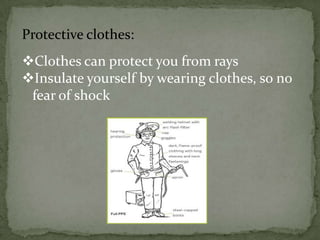

Electric arc welding involves melting metal parts together at points of contact using an electric arc. It can only join parts made of the same metal. The process requires a workpiece, electrode, electrode holder, cables, welding table, and a power source. Welding should not occur below 25°C or above 70% humidity to prevent cracks and rust. Arc welding is important for infrastructure like pipes, vehicles, electricity towers, and tanks. Successful welding depends on selecting the correct welding current and electrode size for the material thickness, as well as proper travel speed, workpiece preparation, electrode angle, and safety equipment like glasses, ear protection, protective clothing, and ventilation.