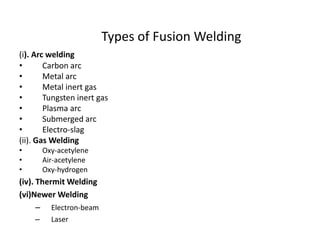

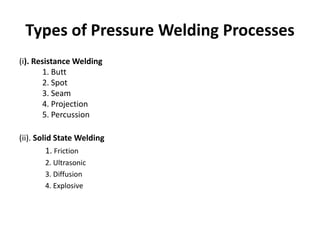

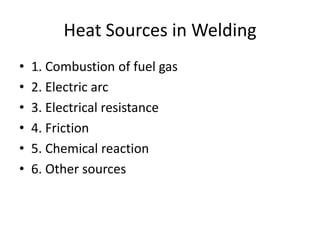

Fusion welding involves melting materials together using heat from sources like gas flames or electric arcs. It allows for joining of metal parts. Solid-state welding uses pressure, and sometimes heat, but no melting, to join metals. Welding is used in many industries like manufacturing, construction, and automotive as it allows for joining of metal parts that would otherwise be difficult or impossible to form as a single piece.