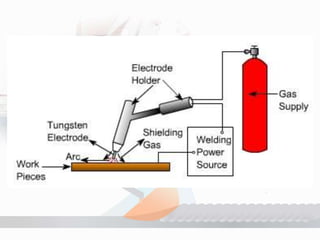

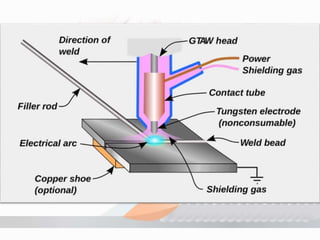

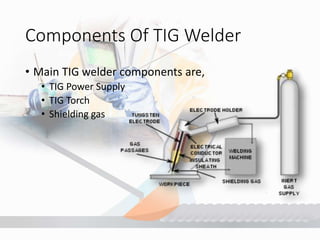

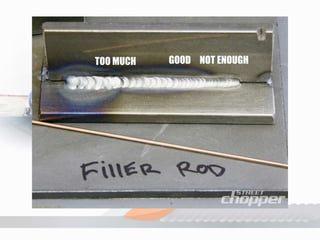

TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to melt and bind metals with the aid of an inert shielding gas to prevent contamination. The process requires heat, shielding, and filler metal, with a focus on precise control and cleanliness, making it suitable for welding thin sections of various metals. While it produces high-quality welds, it is slower and more expensive compared to other welding processes.