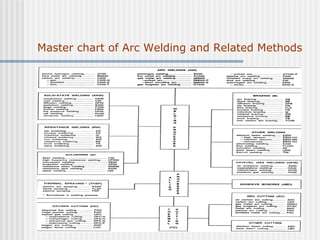

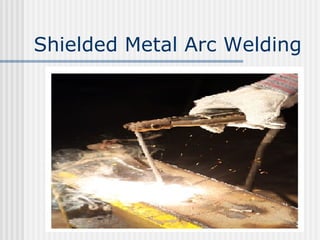

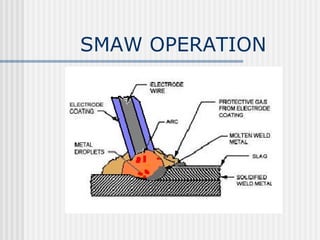

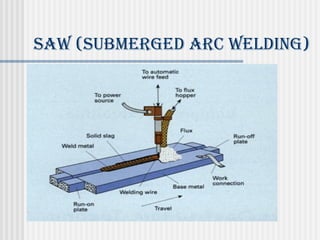

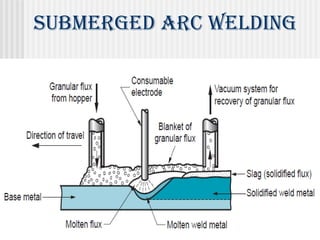

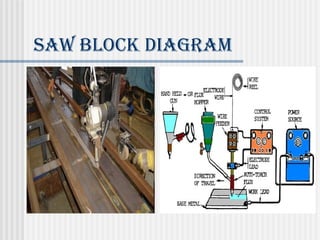

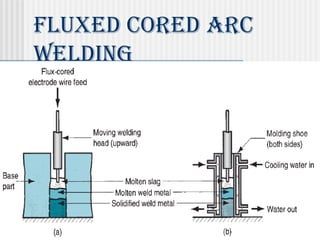

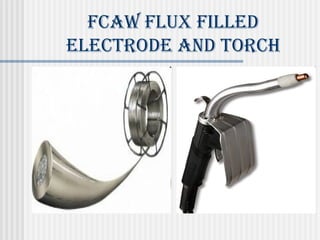

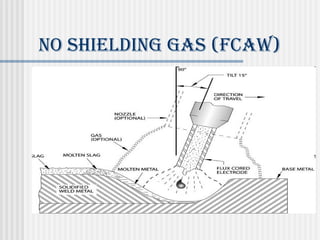

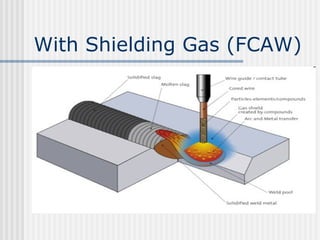

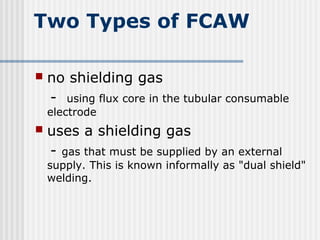

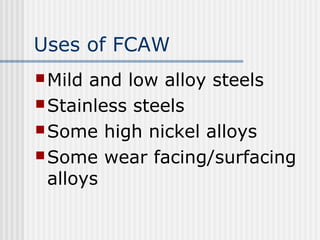

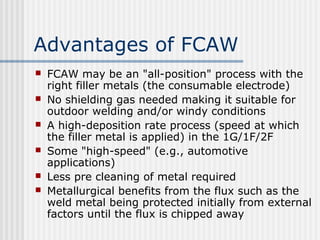

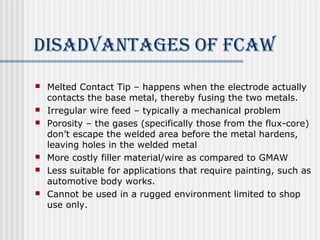

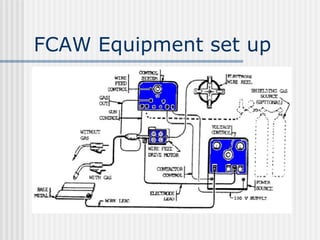

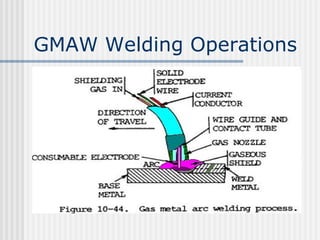

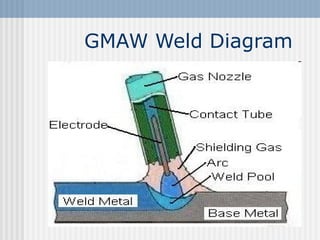

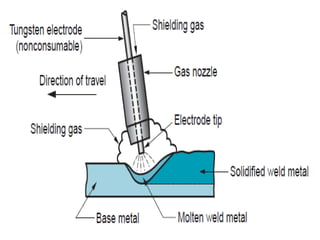

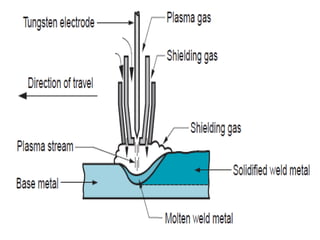

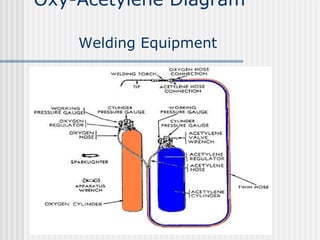

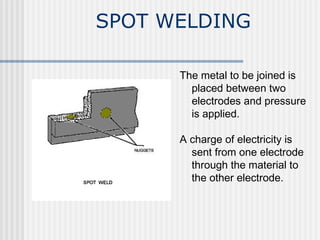

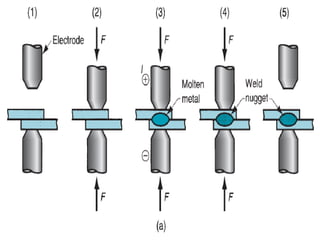

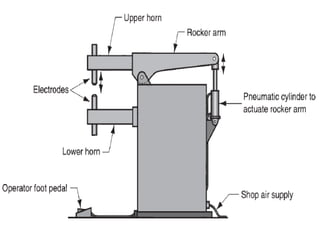

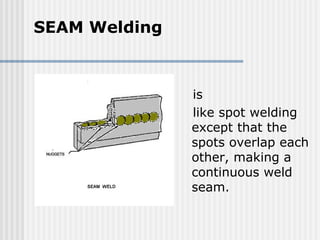

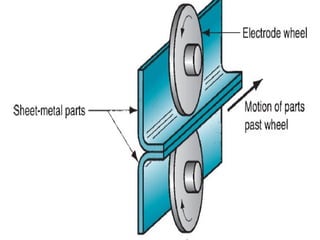

This document provides information on various welding processes and techniques. It begins by defining welding as joining metals through heat, pressure, or both. It then lists and describes common welding types including arc welding, oxyfuel gas welding, and resistance welding. The document focuses on explaining different arc welding processes such as shielded metal arc welding, submerged arc welding, flux-cored arc welding, gas metal arc welding, gas tungsten arc welding, plasma arc welding, and carbon arc welding. It also provides brief descriptions of oxyfuel gas welding and resistance welding.