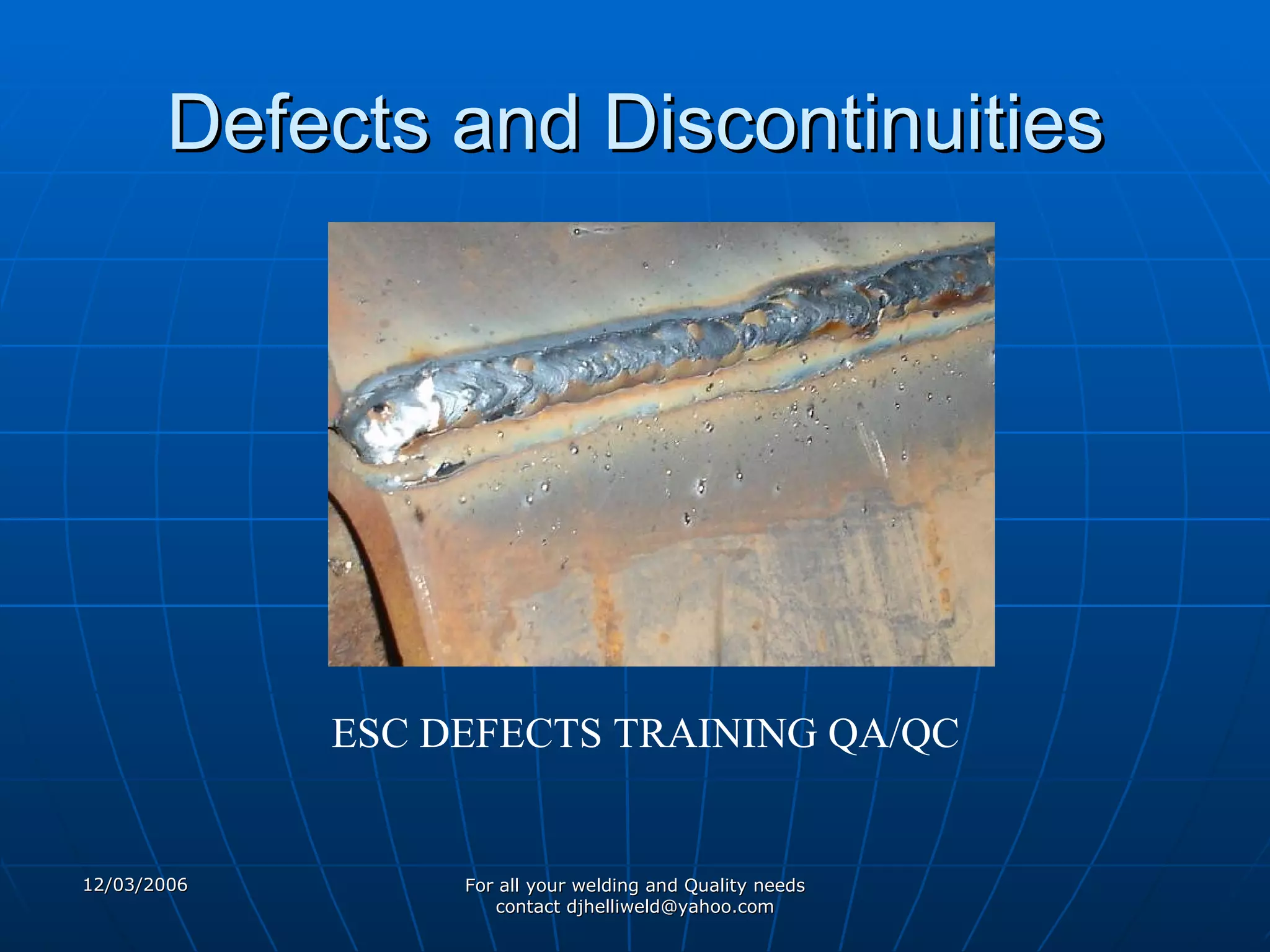

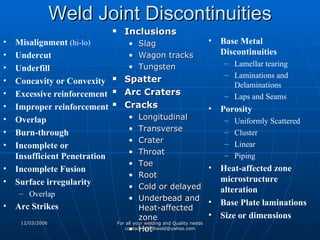

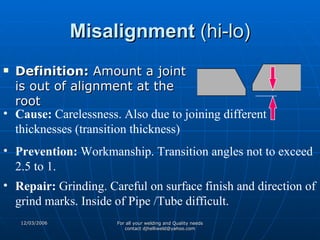

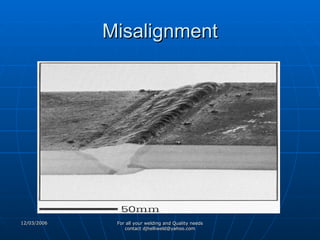

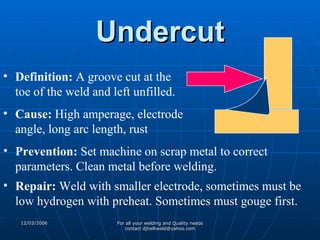

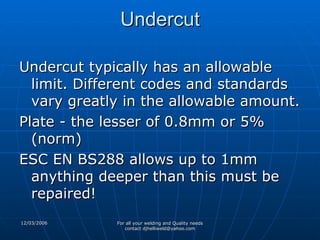

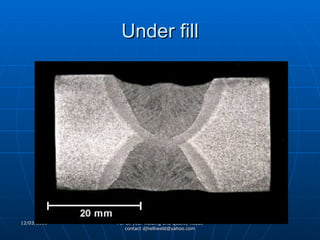

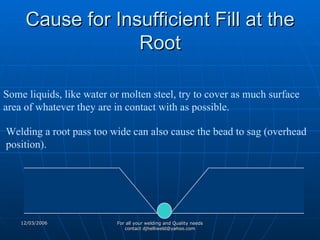

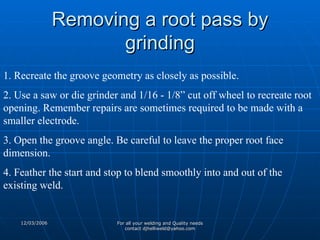

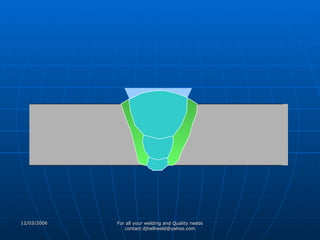

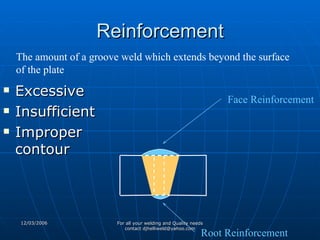

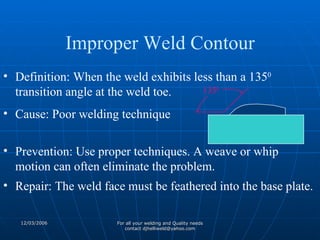

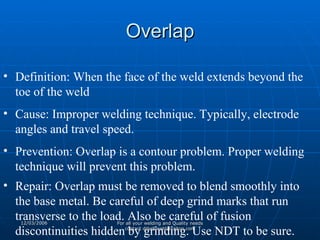

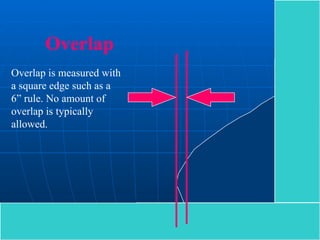

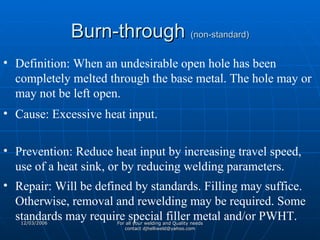

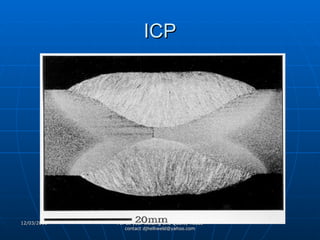

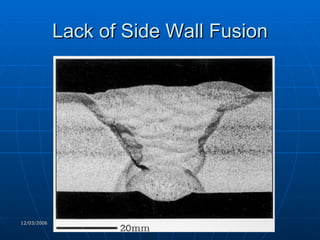

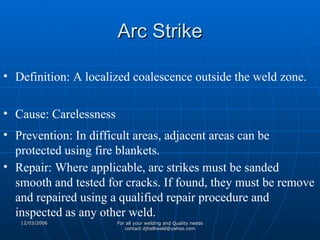

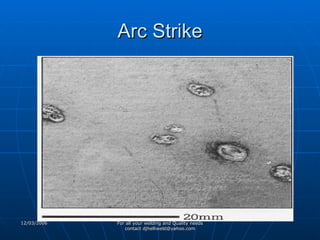

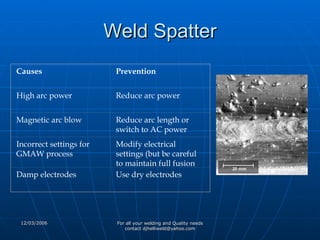

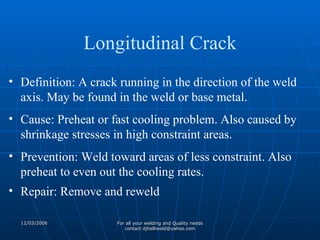

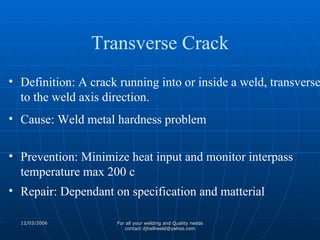

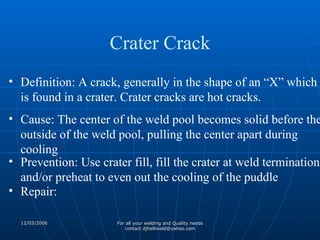

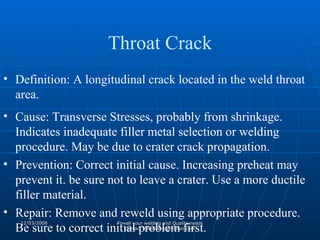

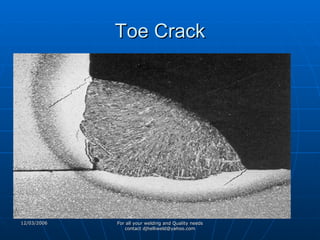

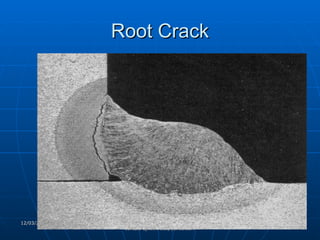

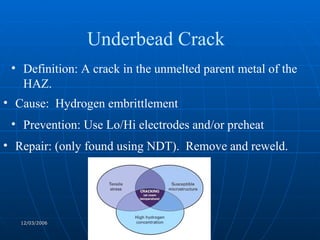

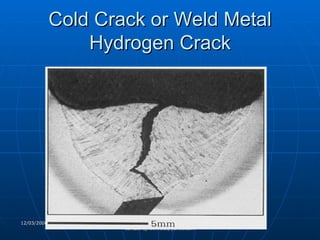

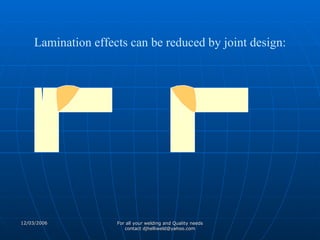

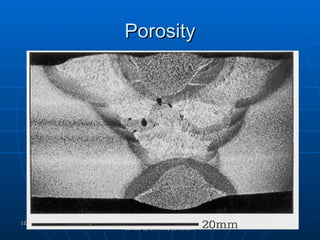

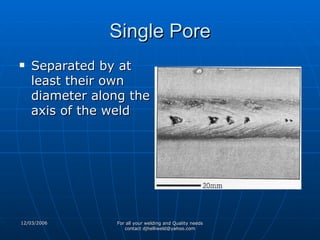

The document outlines various defects and discontinuities in welding, defining terms such as defects, discontinuities, and specific examples like undercuts and porosity. It describes causes, prevention methods, and repair strategies for these issues, emphasizing the importance of adhering to standards and cost-effective practices. The text serves as a comprehensive training guide for quality assurance and control in welding processes.