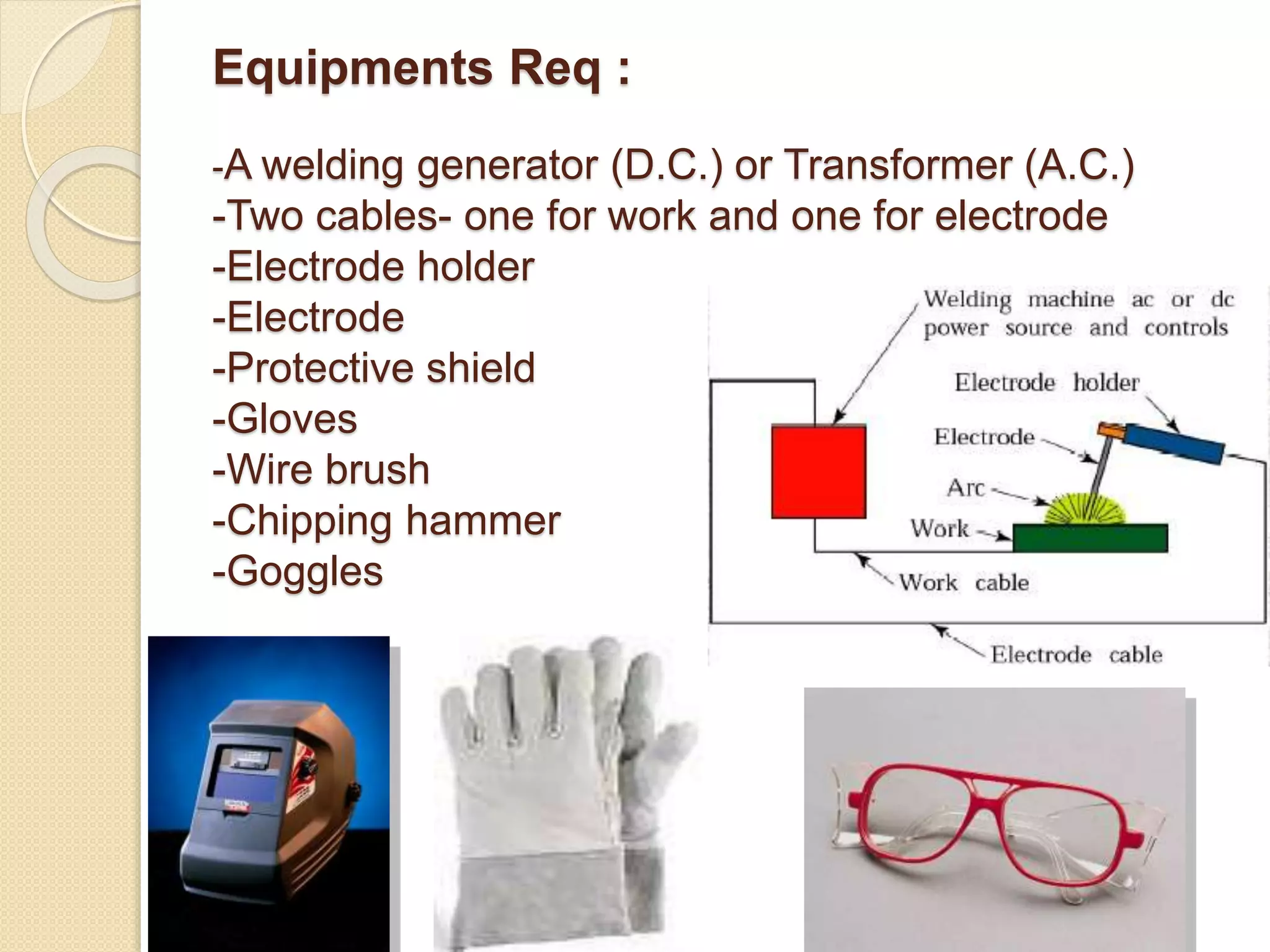

Arc welding is a process that joins metals by heating them with an electric arc between an electrode and the metals, which allows for the metals to melt and bond together. It involves applying an electric current through an arc that is struck between the base metal and a consumable electrode or non-consumable electrode. The arc heats and eventually melts the base metal, and optionally filler metal is added from the electrode. The filler metal mixes with the base metal as it solidifies, creating a strong joint. Arc welding is commonly used due to its versatility, simplicity, and efficiency for welding metals like steel and aluminum. Personal protective equipment is required due to the heat, light, and fumes involved.