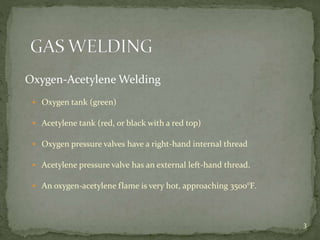

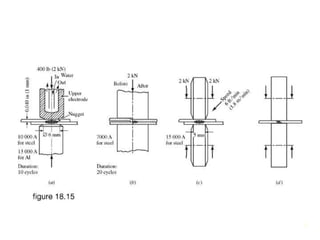

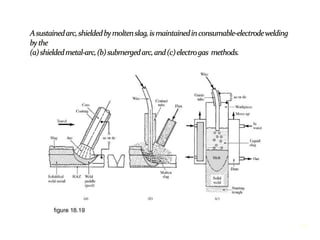

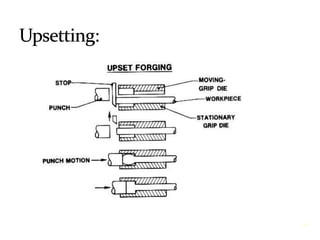

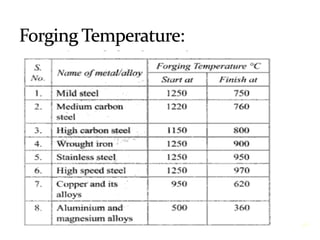

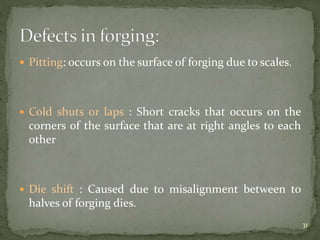

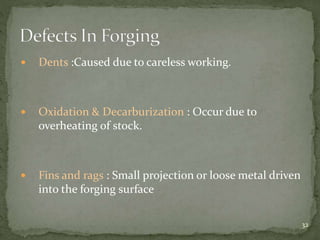

The document details various metal joining and shaping techniques, including welding methods such as oxygen-acetylene welding, resistance welding, and forge welding. It describes the advantages of these methods, the processes involved in forging, and the significance of temperatures and equipment used in metalworking. Additionally, it covers common defects encountered during these techniques, emphasizing the importance of precision and the tools required.