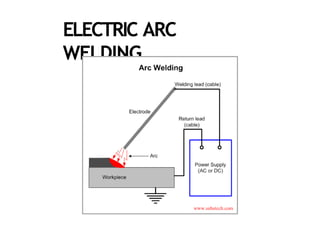

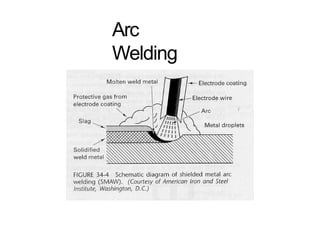

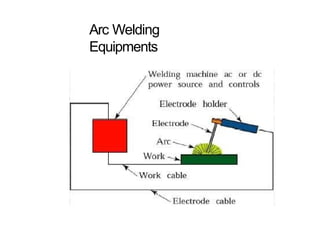

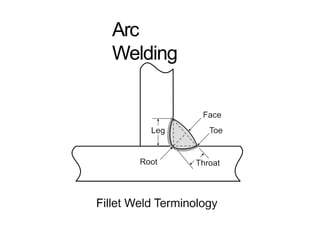

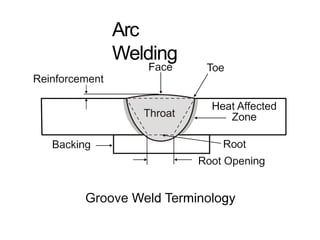

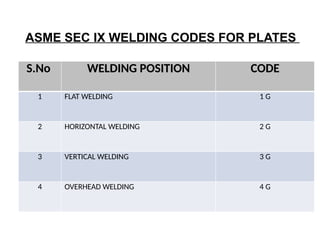

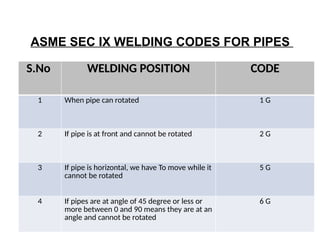

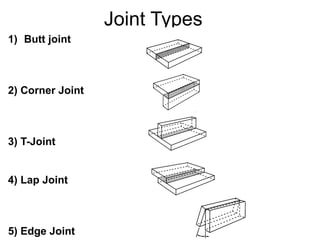

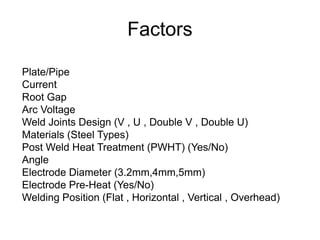

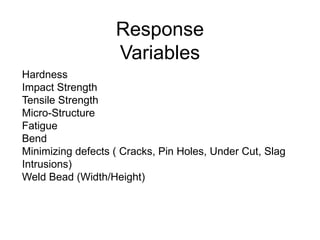

The document discusses electric arc welding, a fusion welding process involving the melting of metals by an electric arc to create a permanent joint. It outlines various welding methods, including shielded metal arc welding, the principles behind welding equipment, electrode functions, and common defects, as well as their advantages and disadvantages. The document also details standards and factors affecting welding, such as material types and welding positions.