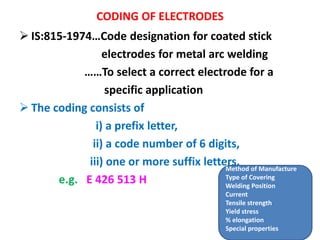

This document discusses welding electrodes and welding processes. It provides specifications for AC transformers and DC generators used in welding. It compares AC and DC arc welding, highlighting differences in power consumption, arc stability, electrode types, polarity, suitability for materials, and efficiency. It also compares MIG and TIG welding processes based on electrode type, feed method, current type, feed material, base metal thickness, and welding speed. The document outlines flux coatings used in electrodes and their ingredients for slag formation, arc stabilization, deoxidization, alloying, and binding. It describes coding systems for electrodes and factors to consider when selecting electrodes, such as the power source, base metal composition, thickness, position, current, and desired mechanical