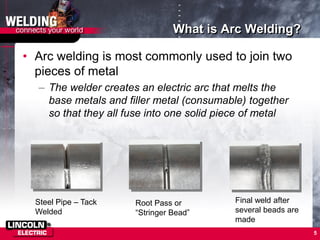

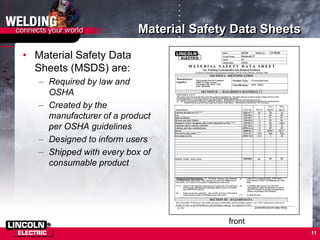

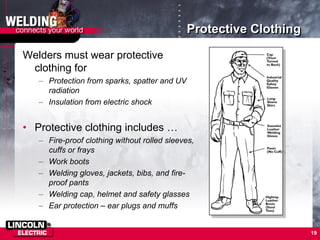

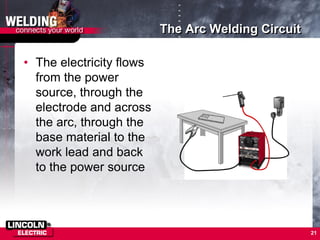

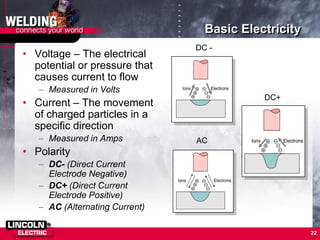

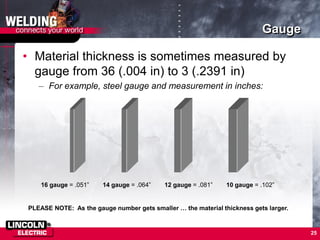

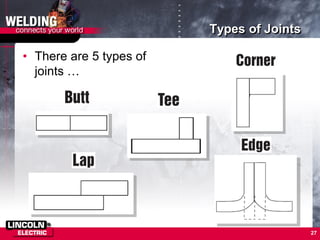

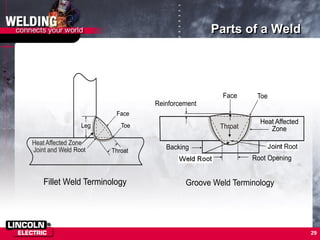

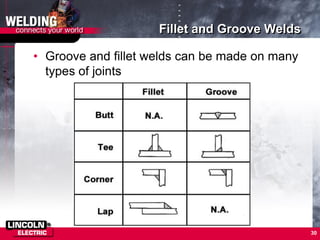

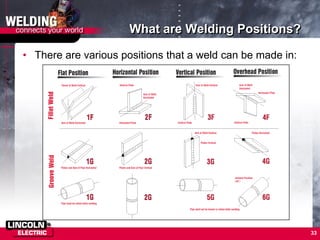

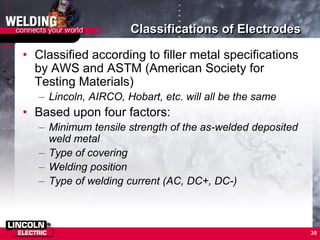

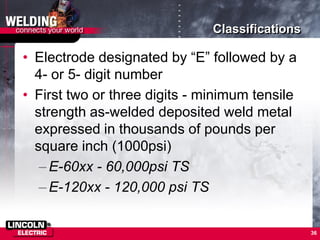

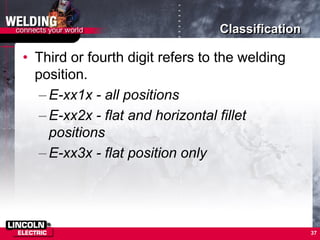

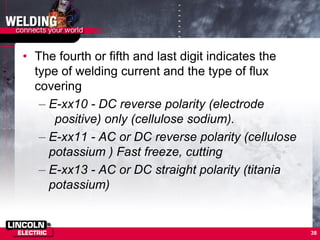

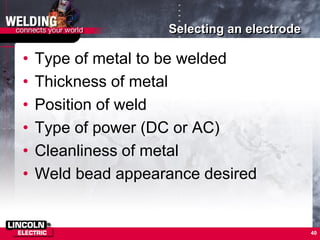

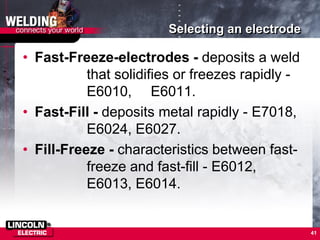

This document provides an overview of arc welding basics. It introduces arc welding and discusses its importance. Safety is emphasized, covering hazards like fumes, electric shock, and fire. The document explains welding fundamentals such as electricity, metals, joints, positions and electrode classification. Key terms are defined and objectives focus on safety, terminology, welding symbols and career opportunities in welding.