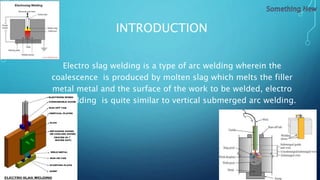

Electro slag welding is an arc welding process where coalescence is produced by a molten slag that melts the filler metal and workpiece surface. During the process, a granular flux is placed in the joint gap and melts when current is applied, forming a 25.4-38.1 mm thick slag blanket. The slag's high resistance causes most of the heating, welding progressively from bottom to top. Advantages include simple joint preparation, ability to weld very thick plates in a single pass economically with low distortion and stress, while disadvantages are limitation to vertical welding and increased grain size and cracking risk.