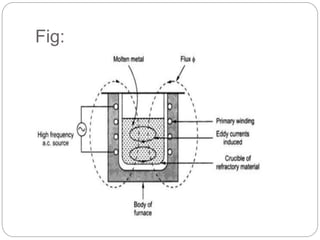

An electric induction furnace uses electromagnetic induction to melt metals through eddy currents induced in the material. It has several advantages over combustion furnaces like faster startup times, more flexibility, and cleaner melting without byproducts. The document describes the basic principles of electromagnetic induction and joule heating used in induction furnaces. It provides details on the construction, types, advantages, and limitations of induction furnaces.