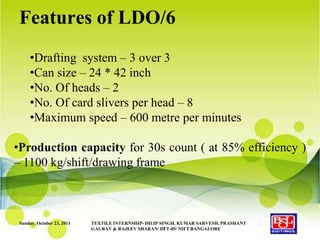

The document discusses the drawing process and machinery used. Drawing involves using a breaker draw frame to parallelize 8 slivers into one, improving regularity. A finisher draw frame is then used to further strengthen the sliver. The key machinery used are LDO/25 and LDO/6 breaker draw frames, and an LRSB-851 finisher draw frame from Rieter. All machinery have features like drafting systems and stop motions to ensure even sliver production.