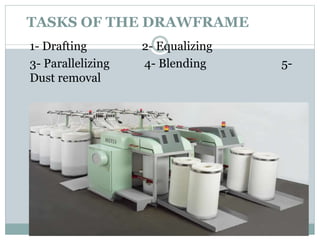

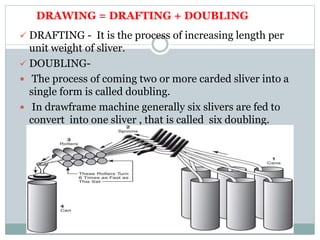

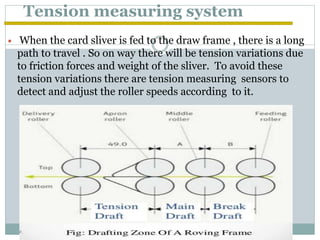

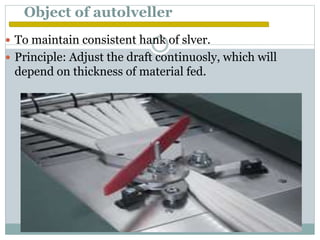

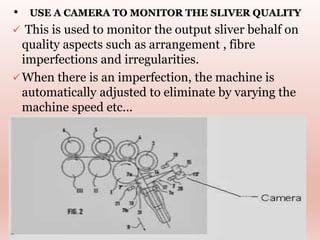

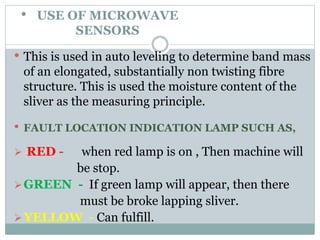

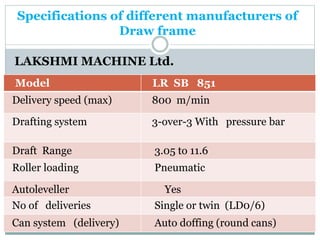

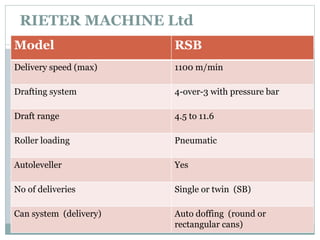

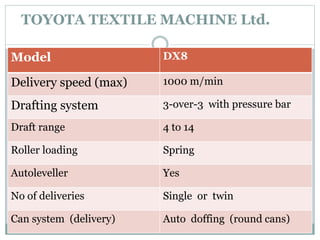

This document discusses the development of drawframes in the spinning process. It describes key components and functions of drawframes, including drafting, doubling, and blending of slivers. Recent developments that improve quality, such as autolevellers and automatic break draft setting, are also covered. The document provides specifications for drawframe models from different manufacturers and concludes by discussing the use of new monitoring technologies like cameras and microwave sensors to further enhance sliver quality.