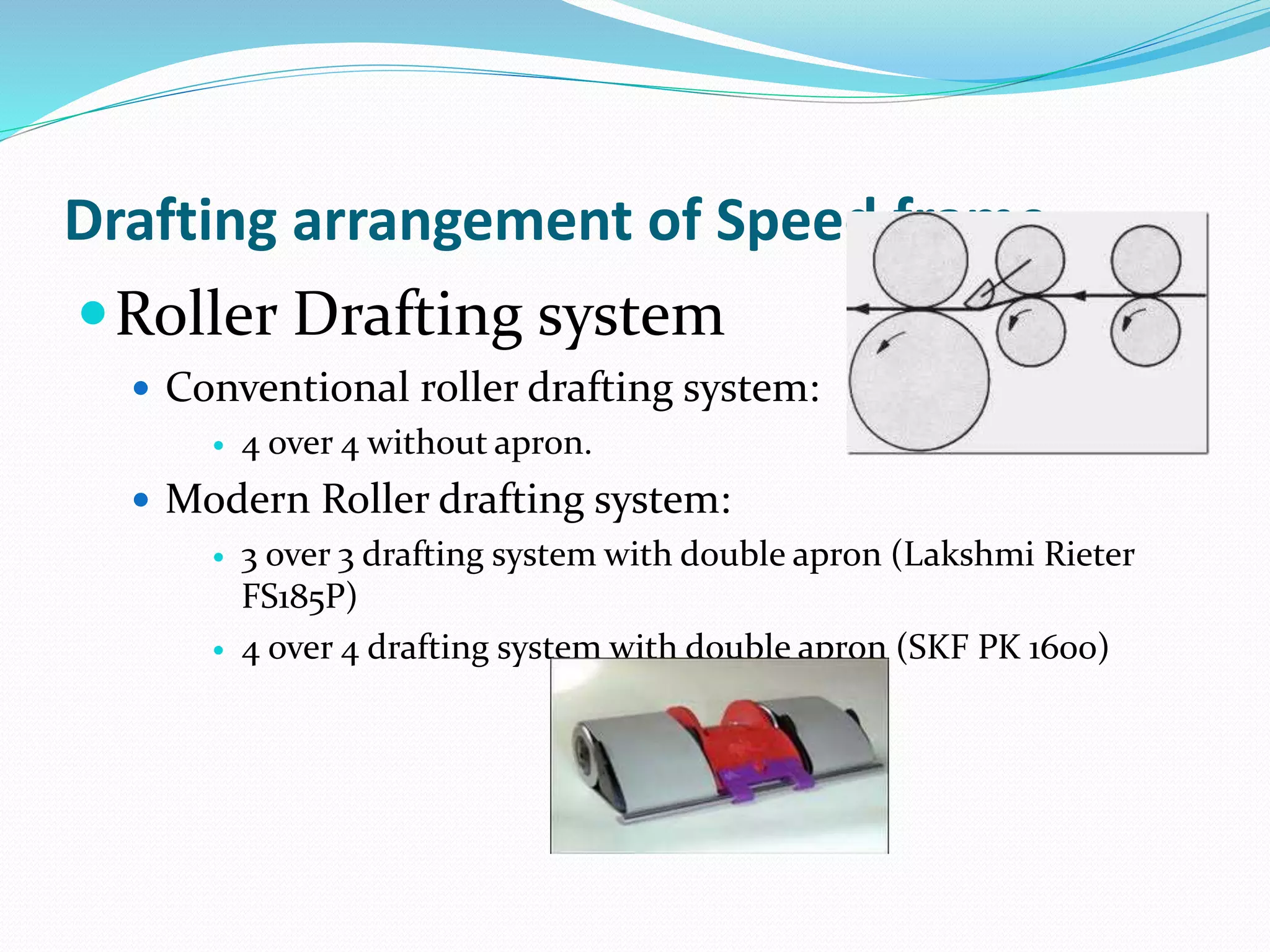

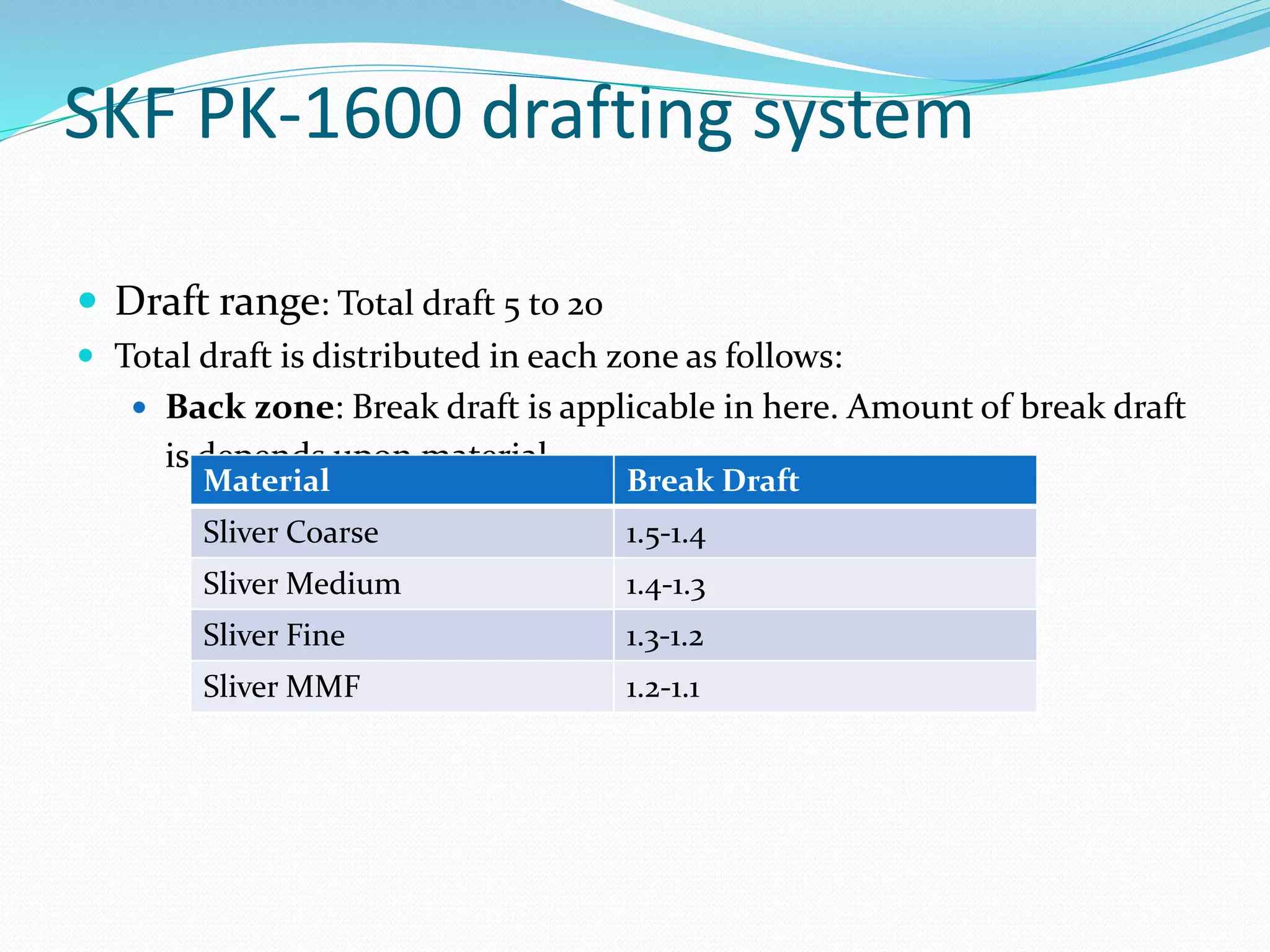

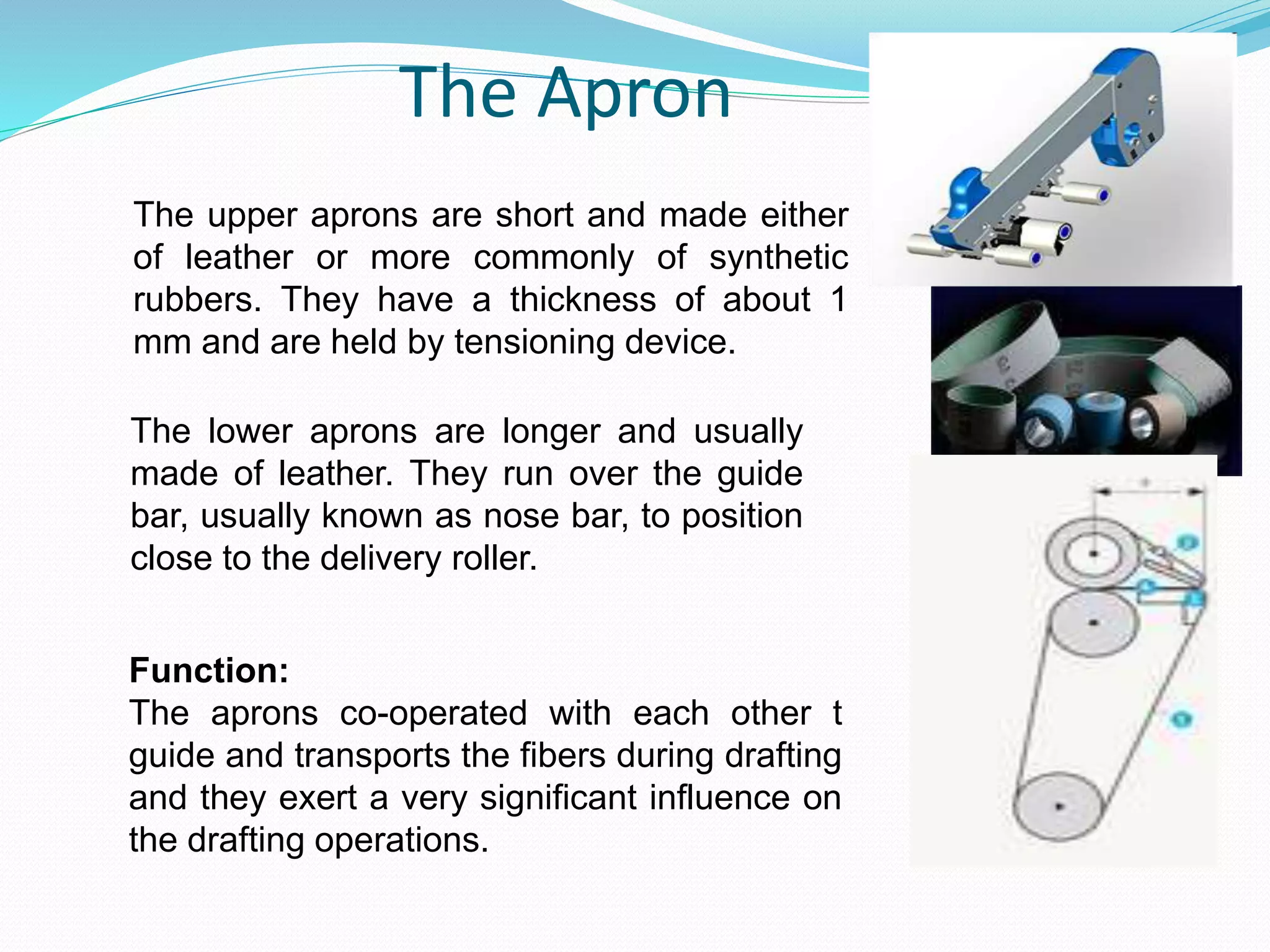

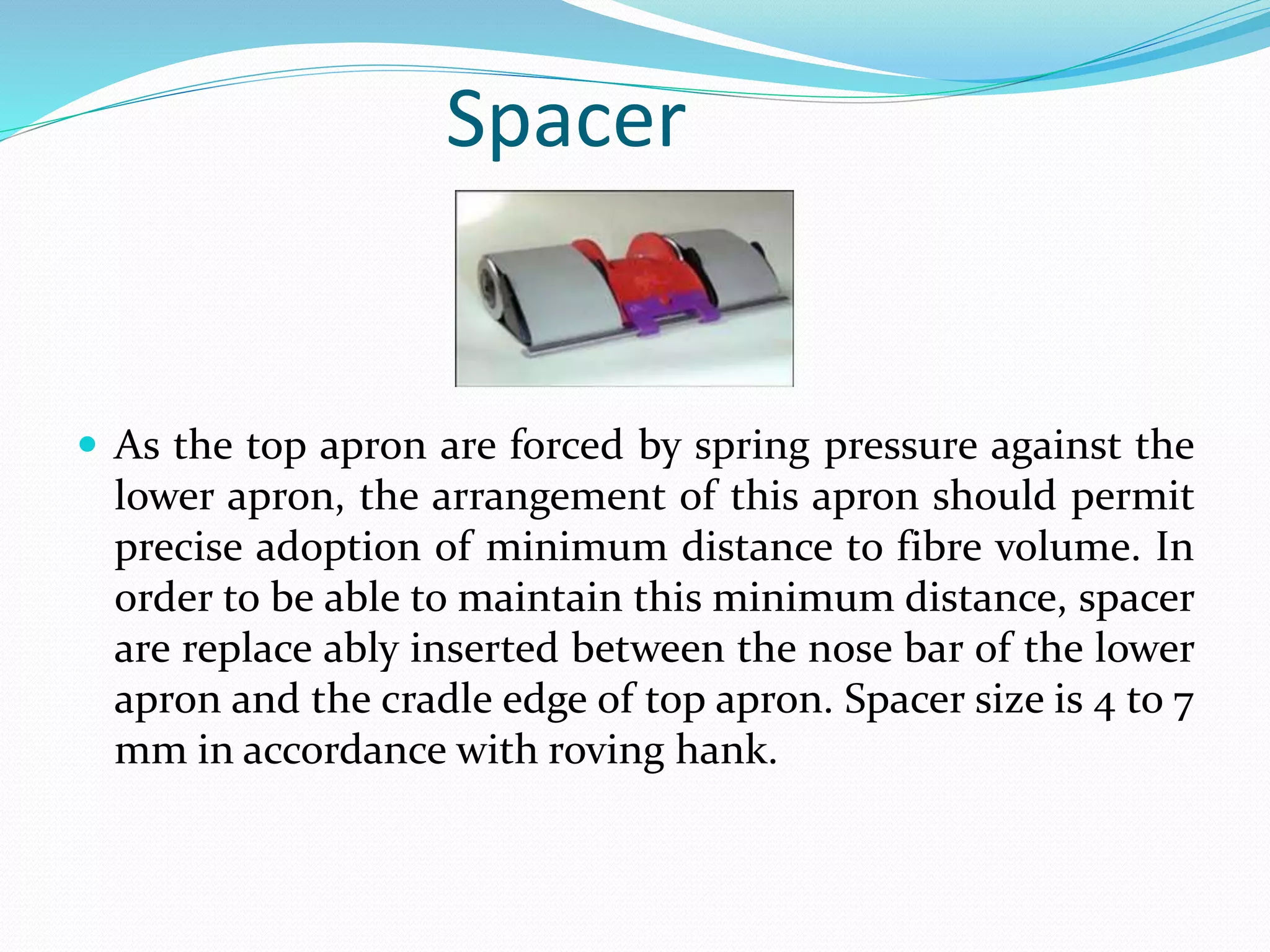

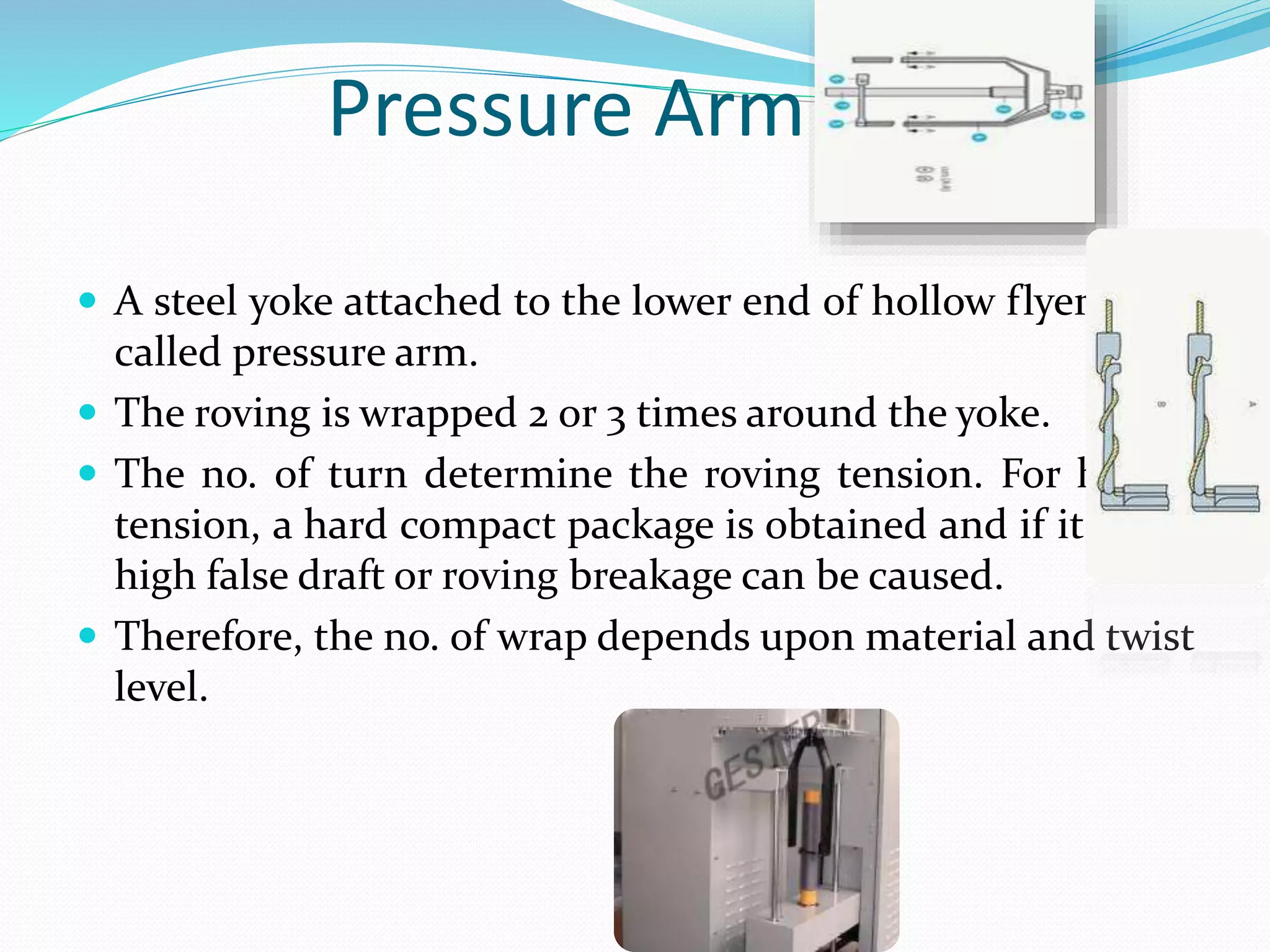

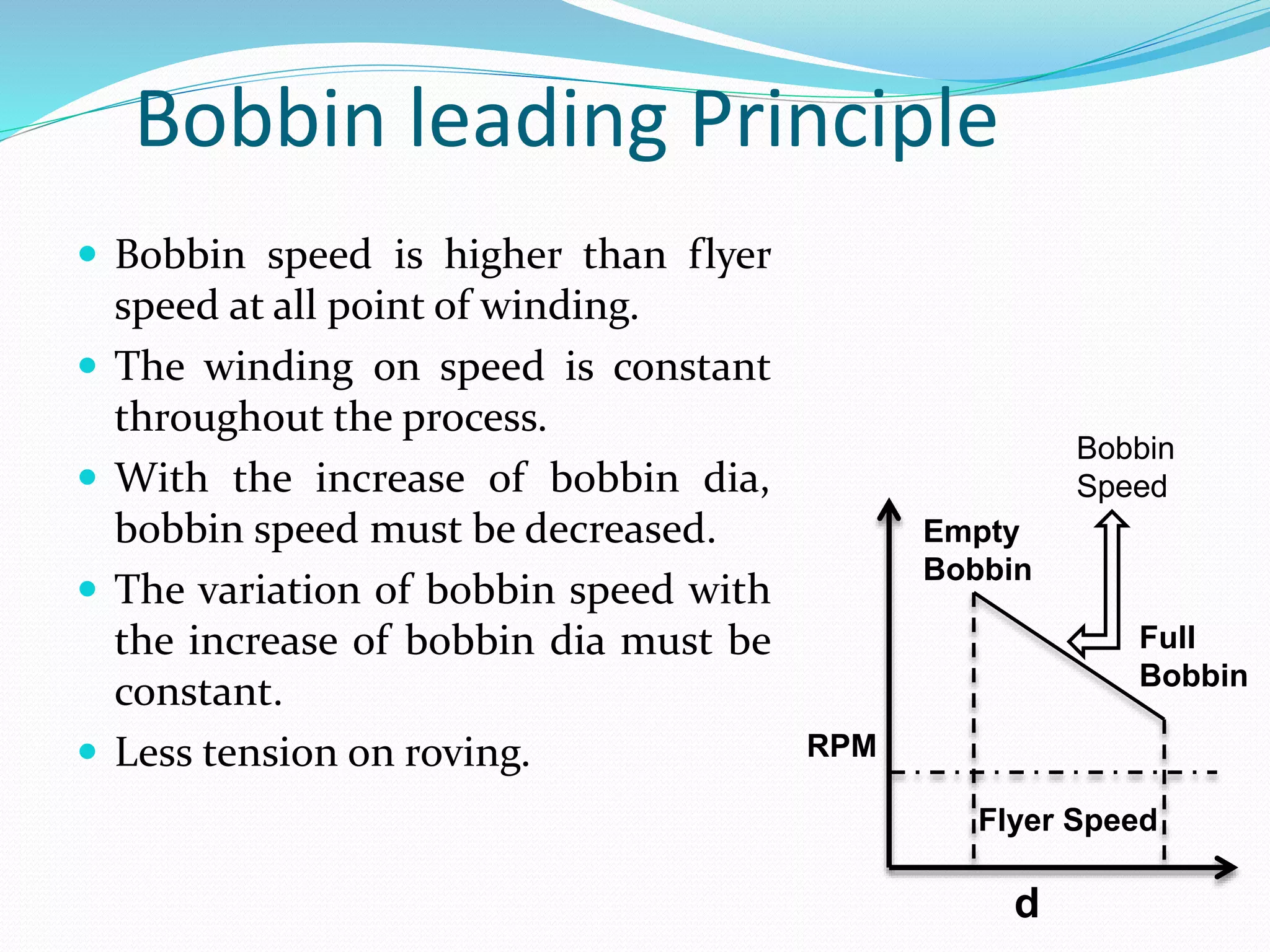

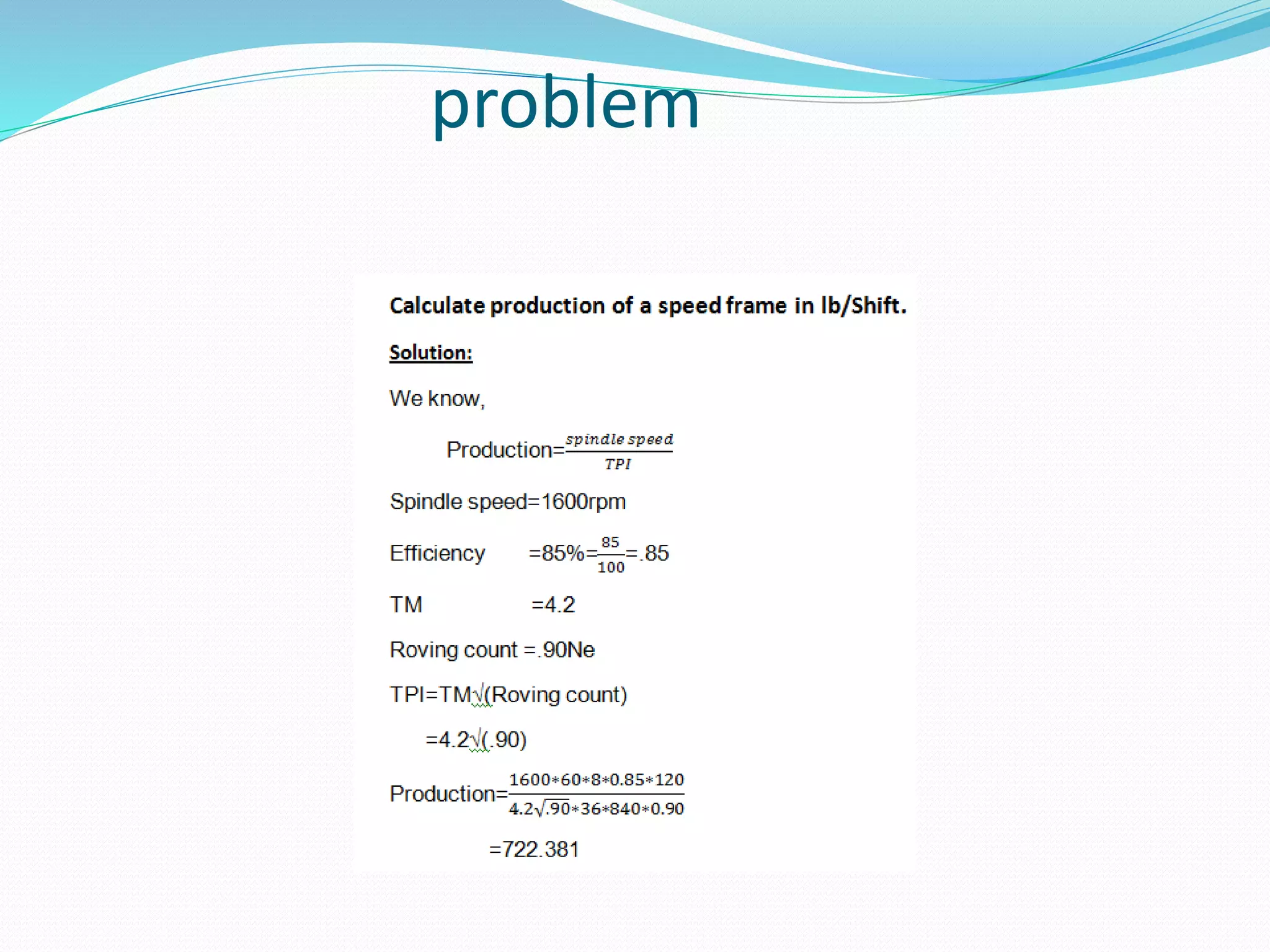

The document discusses the objectives and operating principles of a speed frame machine. It provides details on the group members working on a presentation about speed frames. The key objectives of the speed frame are drafting, twisting, and winding roving onto bobbins. It describes the drafting system, which uses multiple rollers and aprons to draft and condense sliver. Twist is imparted using a flyer and spindle, and roving is wound onto bobbins using the bobbin leading principle. Potential faults on the machine are also listed.