This document provides information about draw frames and their purpose and function. It can be summarized as follows:

1) Draw frames are machines that combine, blend, level, and attenuate slivers through a series of roller pairs to improve sliver quality and evenness. This helps produce higher quality yarn.

2) The key objectives of draw frames are to equalize and parallelize fibers, blend slivers, and remove dust. This straightens and aligns fibers to improve uniformity.

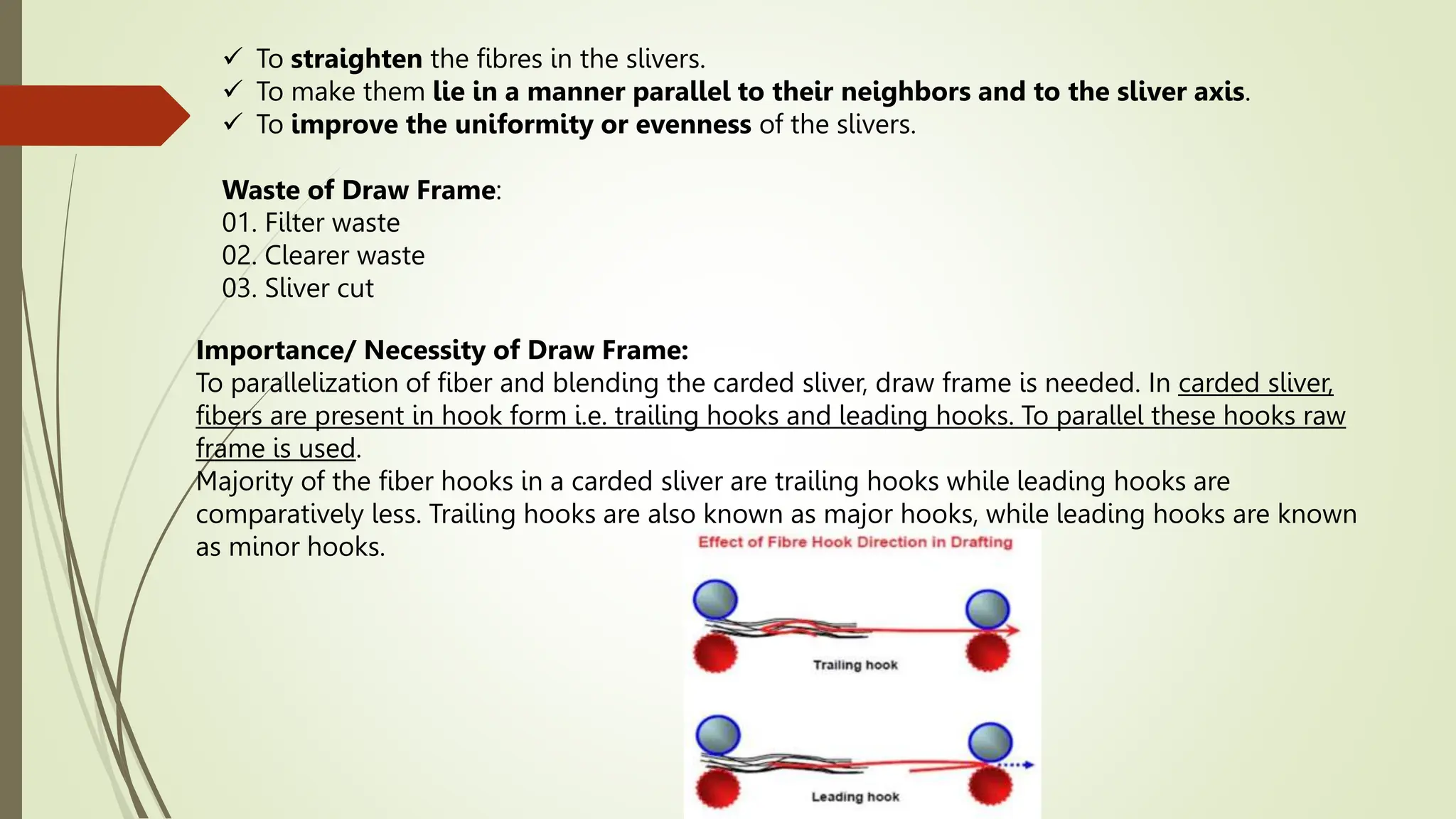

3) Draw frames are necessary to parallelize fibers in carded slivers and blend the slivers. They help straighten fibers from their hooked shape into a parallel arrangement.