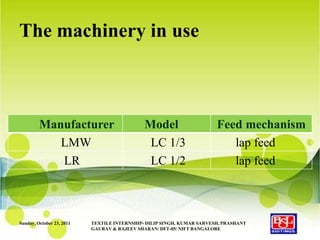

The document summarizes the components and operating parameters of a carding machine. It describes the objectives of carding, the machinery used including manufacturer and model. It lists the components of the carding machine and provides the technical parameters such as diameters of rollers and their speeds. It also outlines the clearance settings between parts and stop motions in the machine.