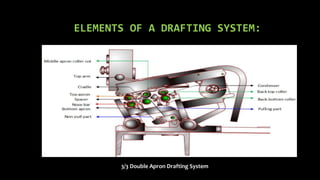

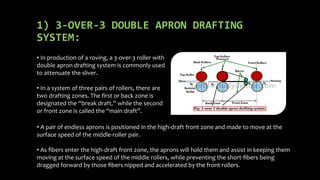

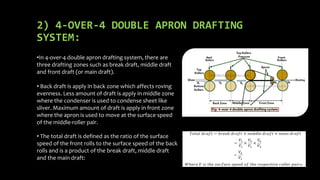

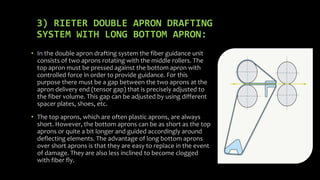

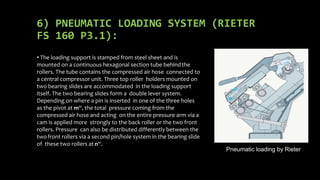

The document discusses various drafting systems used in yarn manufacturing, specifically focusing on double apron drafting systems and their configurations such as the 3-over-3 and 4-over-4 systems. It explains the importance of drafting in controlling fiber evenness and strength through different drafting zones and mechanisms. The document also highlights advancements like the Casablanca A500 and pneumatic loading systems that enhance drafting efficiency and fiber management.