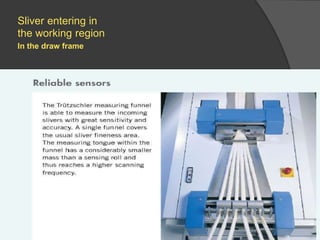

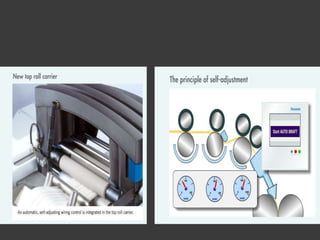

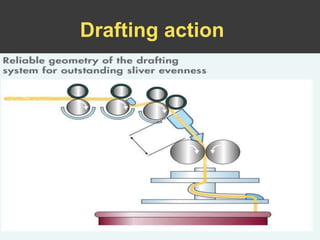

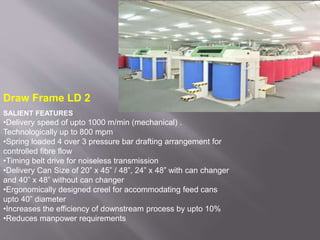

The document discusses developments in draw frame technology. Recent developments include higher production rates up to 1000 m/min, improved drafting systems like 4-over-3 with pressure bars, automatic sliver regularity controllers, quality monitoring systems, automatic doffing systems, and pre-set sliver length measuring. Additional new developments mentioned are automatic break draft setting, clean coil technology to reduce cleaning needs, pneumatic pressure heads for rollers, and tension measuring systems.