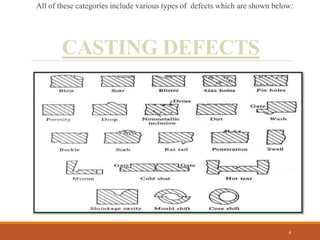

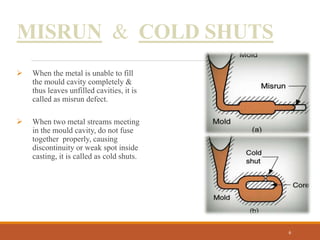

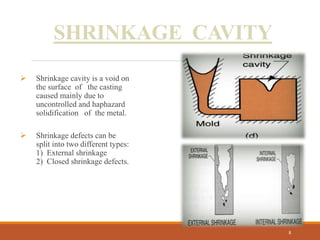

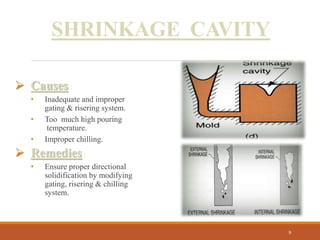

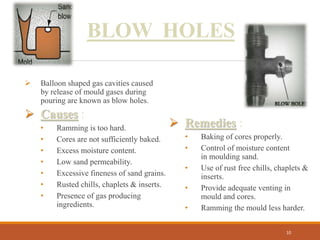

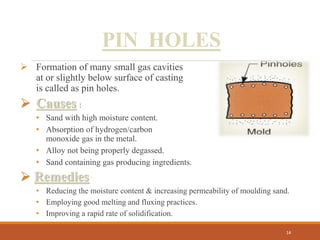

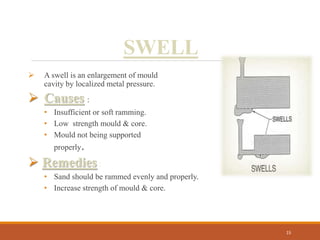

This document discusses various types of casting defects including their causes and remedies. It describes defects such as mismatch, misrun, cold shuts, shrinkage cavities, blow holes, porosity, hot tears, metal penetration, pin holes, swell, drop, and rat tails/buckles. The document explains that casting defects occur due to issues in the casting process involving gases, moulding materials, pouring metal, and metallurgy. Remedies involve modifications to the gating system, pouring process, sand properties, alloy composition and casting design.