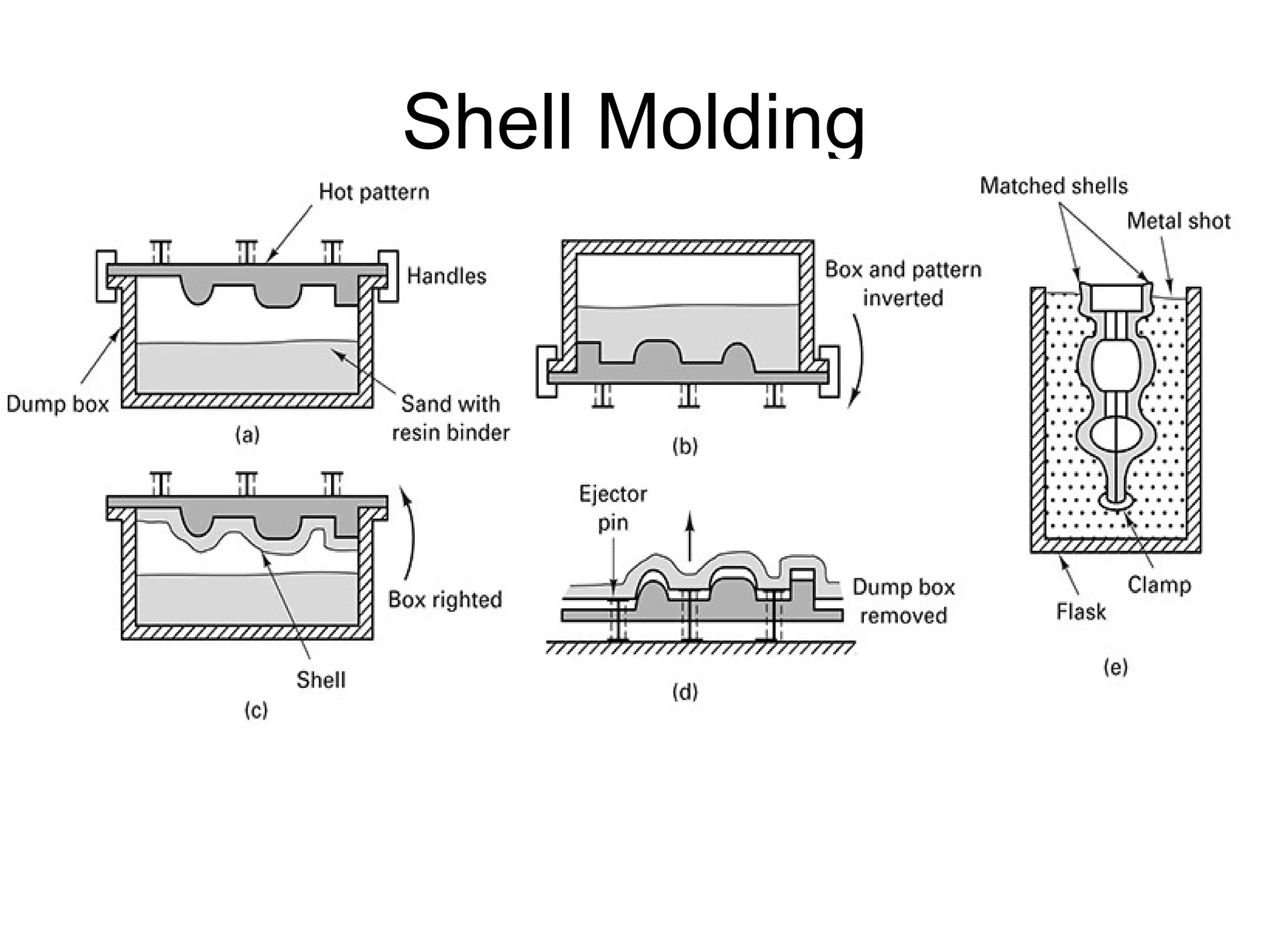

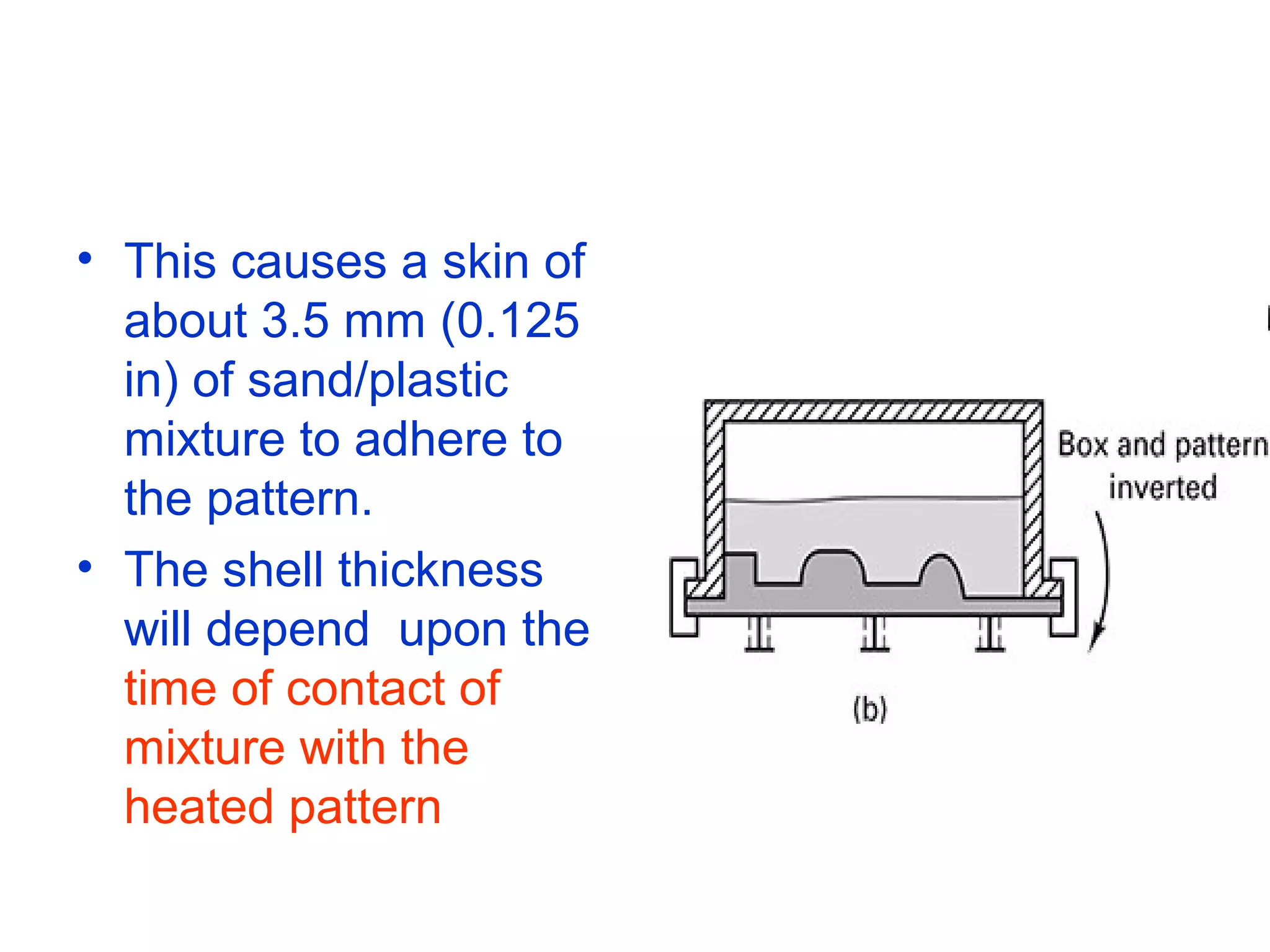

1. Shell casting involves making a shell mold by applying a mixture of sand and thermosetting resin to a heated metal pattern. This allows for casting of parts with complex shapes and good surface finish tolerance.

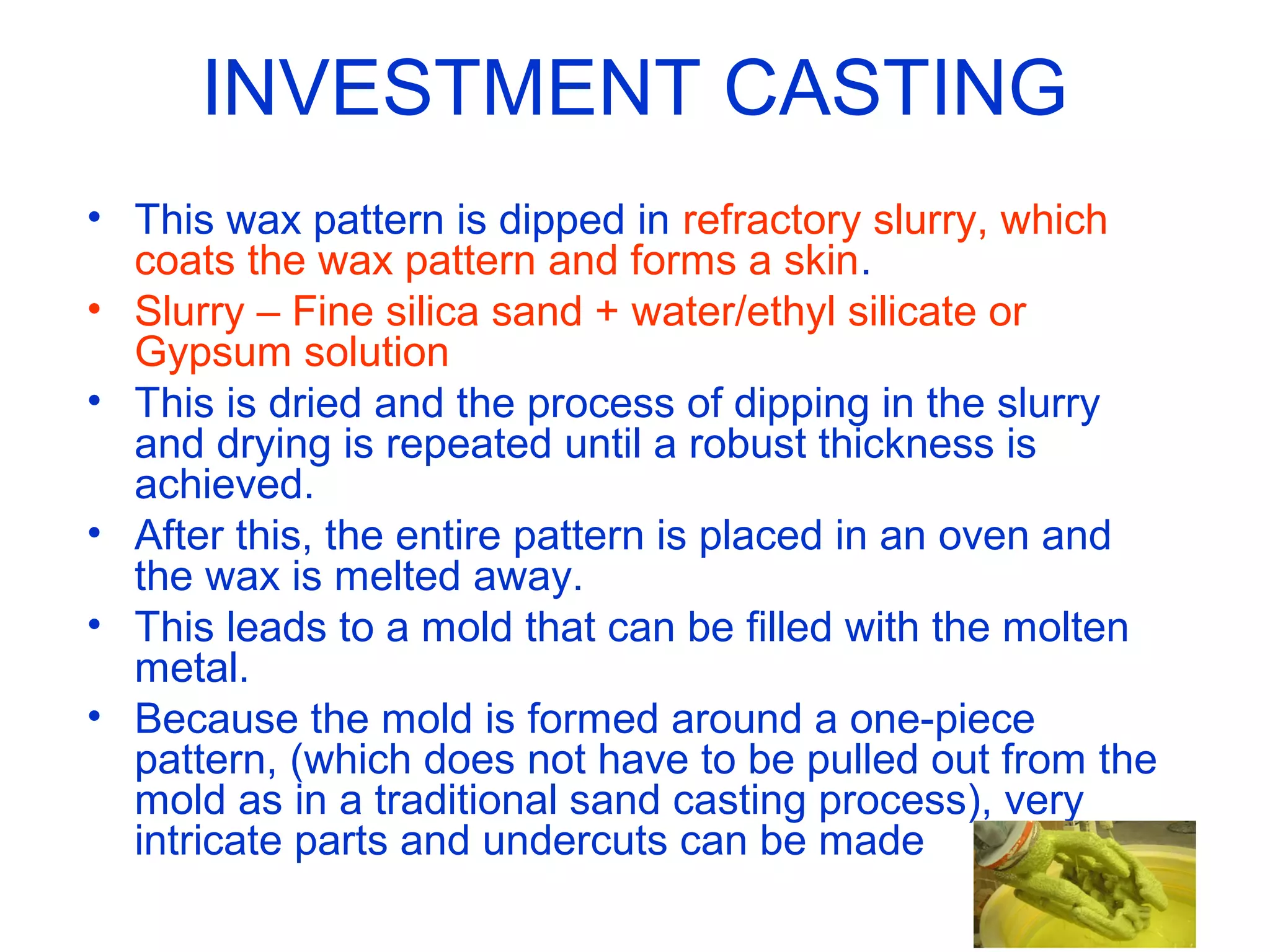

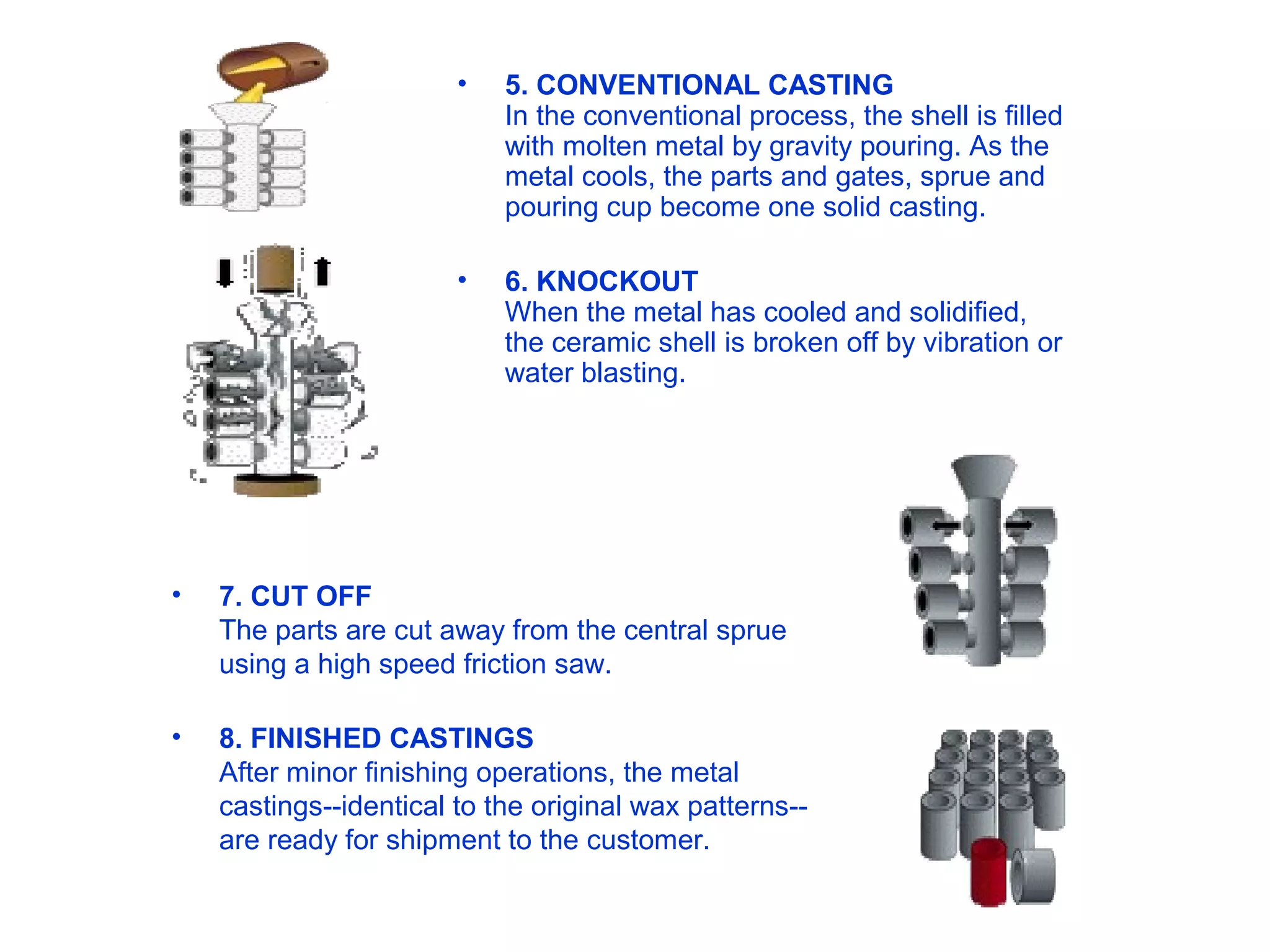

2. Investment casting, also called lost-wax casting, involves making a wax pattern that is coated with refractory material to form a ceramic mold, melting out the wax to leave a cavity for molten metal. This enables production of parts with intricate details and close tolerances.

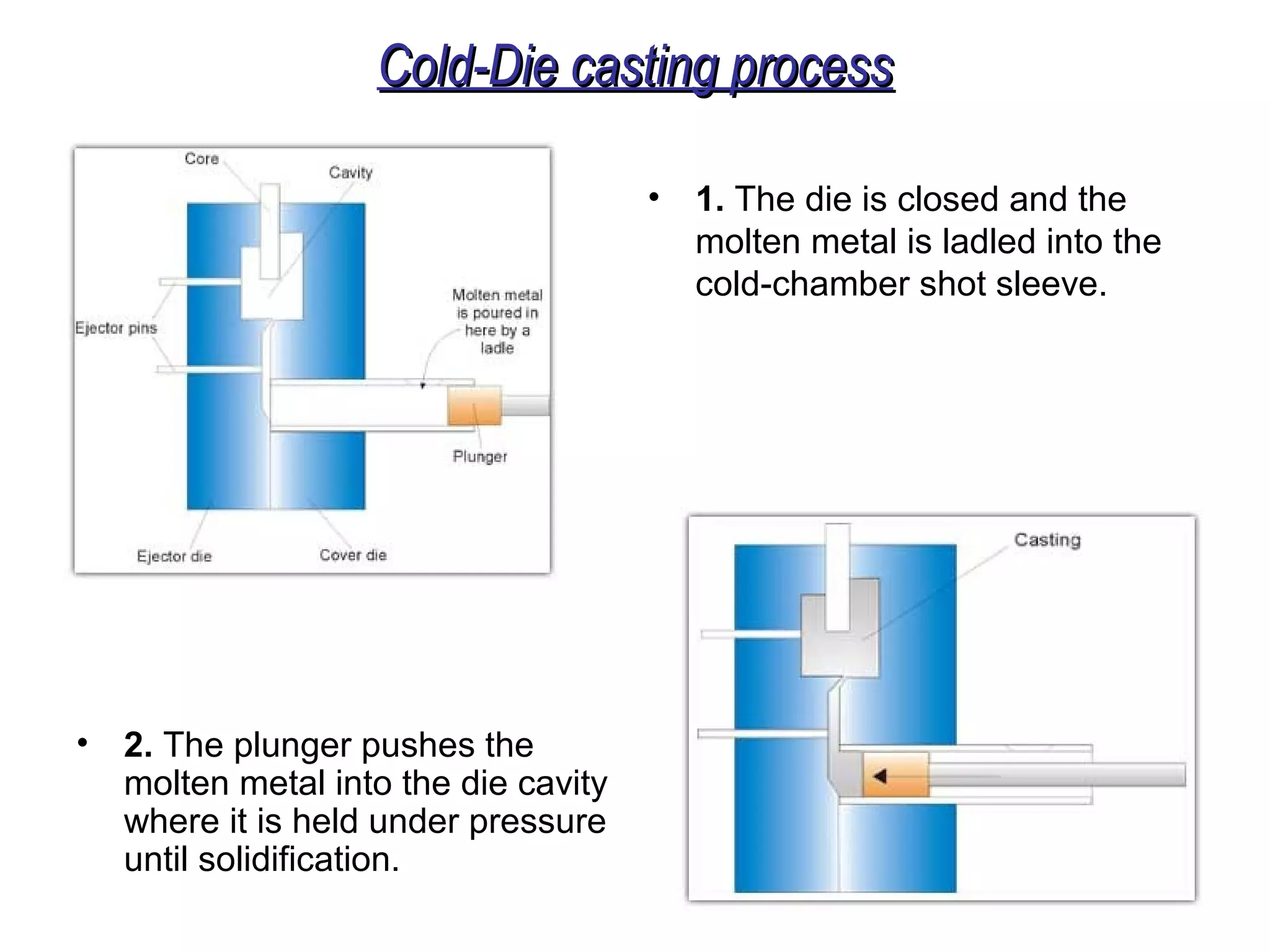

3. Die casting uses high pressure to force molten metal into molds, allowing precise replication of complex shapes. It is well-suited for producing parts from non-ferrous alloys in high volumes.