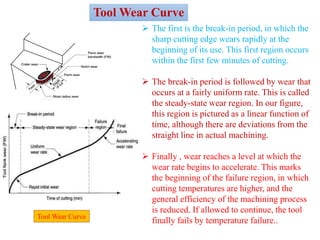

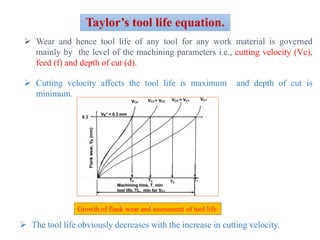

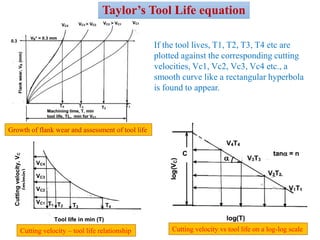

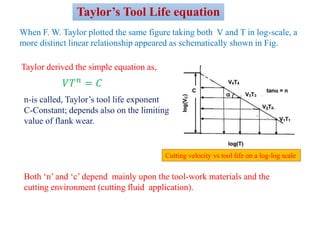

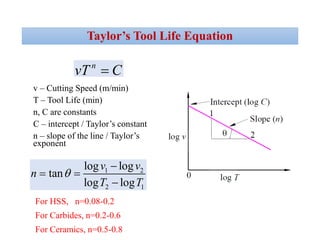

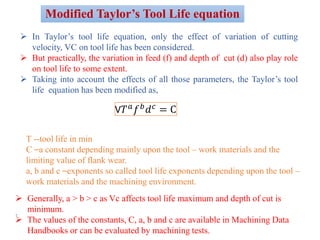

Tool life refers to the amount of time a cutting tool can machine material satisfactorily before needing replacement or reconditioning. It is measured in actual machining time, number of pieces cut, material volume removed, or cutting length. Tool life depends mainly on cutting parameters like velocity, feed, and depth of cut. Initially, tool wear is rapid but then levels off into a steady state wear region before accelerating again towards failure. Taylor's tool life equation models the relationship between cutting velocity and tool life, showing they are inversely proportional. The equation has since been modified to also account for the effects of feed and depth of cut on tool life.