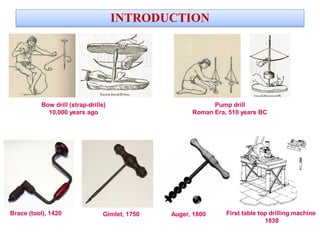

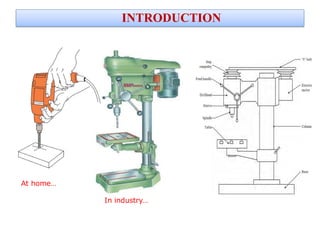

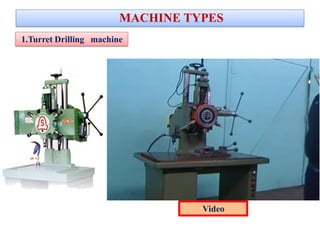

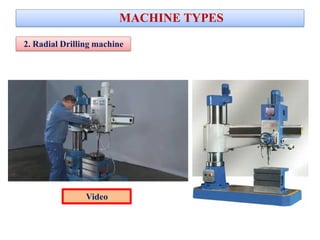

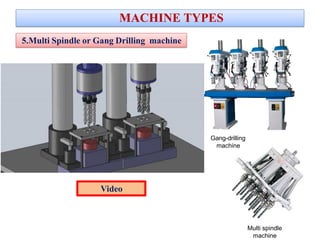

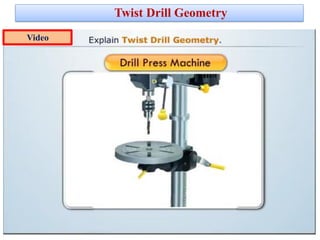

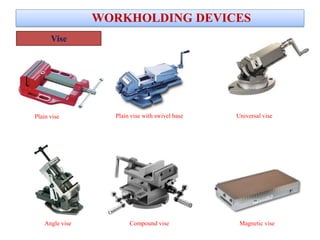

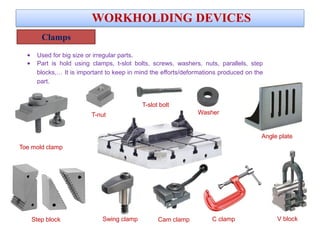

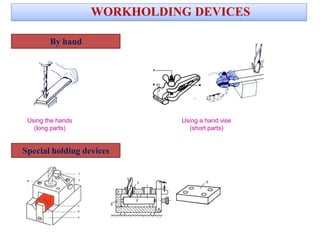

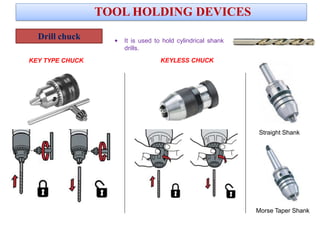

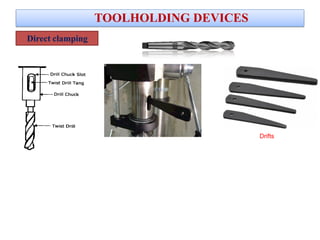

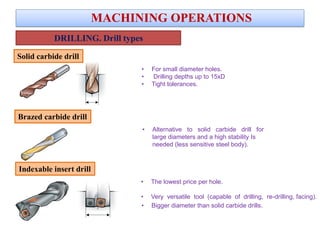

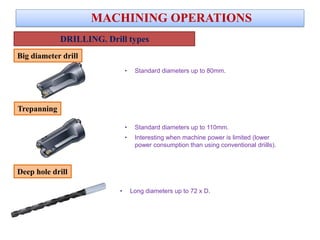

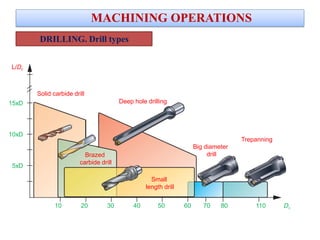

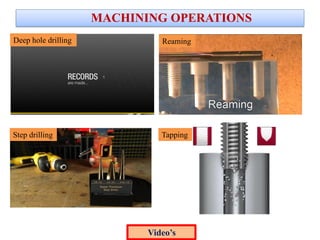

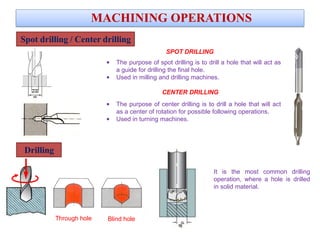

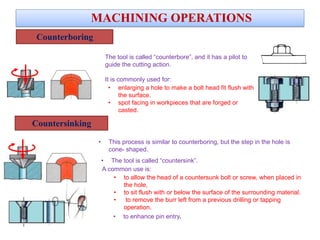

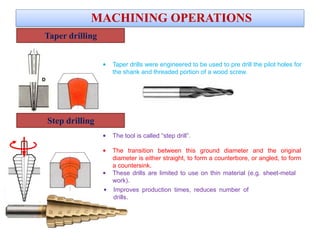

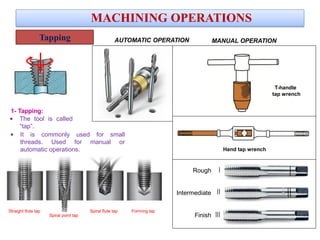

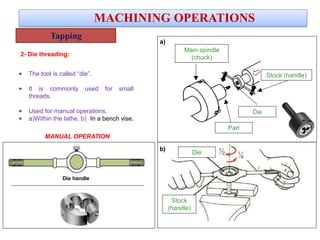

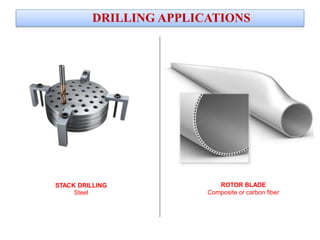

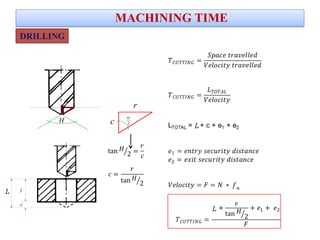

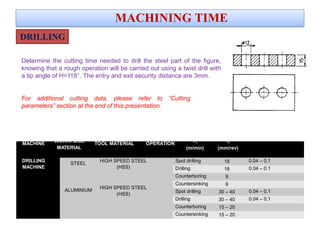

Drilling involves making cylindrical holes using rotating cutting tools. There are various drilling machine types including turret, radial, pillar, and CNC drilling machines. Key aspects of drilling include tool geometry, workholding devices, tool holding devices, and common machining operations like drilling, reaming, tapping, and counterboring. Cutting parameters like speed, feed rate, and cutting time calculations depend on factors like material, tool material, and operation type.