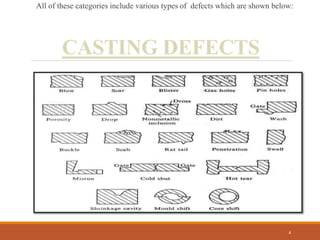

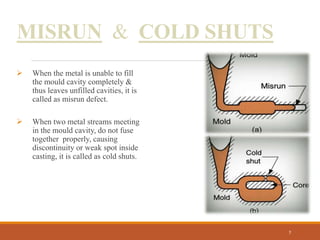

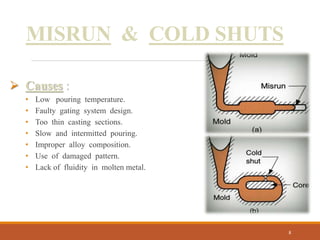

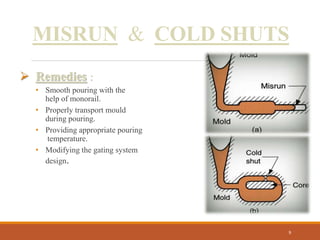

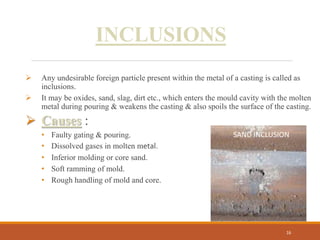

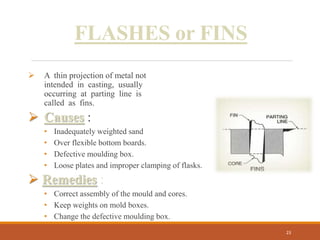

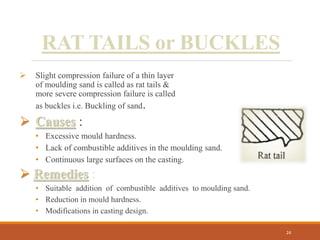

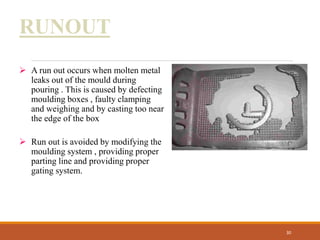

This document discusses various types of casting defects, their causes, and potential remedies. It begins by defining a casting defect and categorizing them into gas defects, shrinkage cavities, moulding material defects, pouring metal defects, and metallurgical defects. Specific defects discussed include mismatch/mould shift, misrun & cold shuts, shrinkage cavity, blow holes, porosity, inclusions, hot tears/cracking, metal penetration, pin holes, swell, drop, flashes/fins, rat tails/buckles, warpage, cracked casting, bent/twisted casting, open blows & blow holes, fusion, runout, and cracks. For each defect, the causes and possible remedies are outlined.