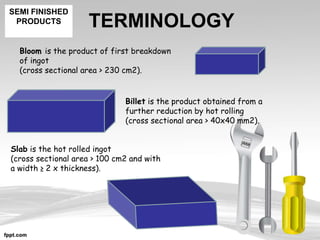

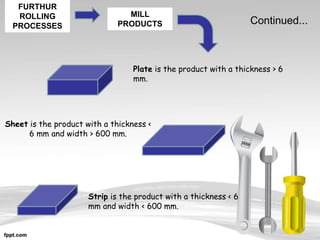

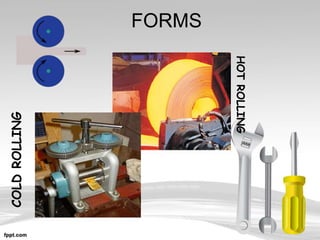

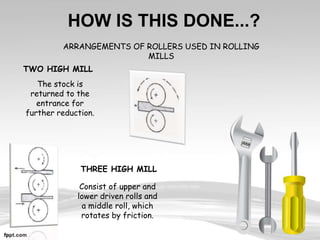

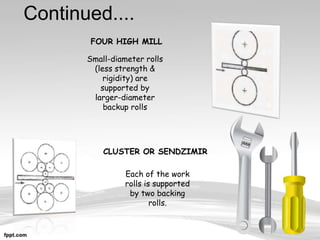

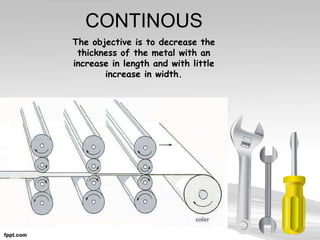

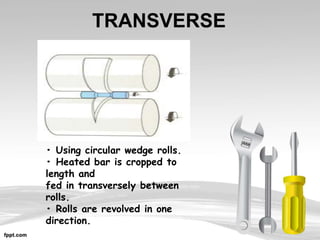

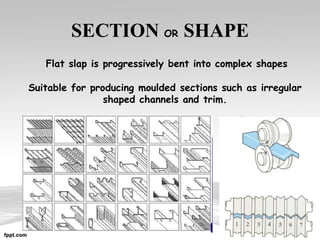

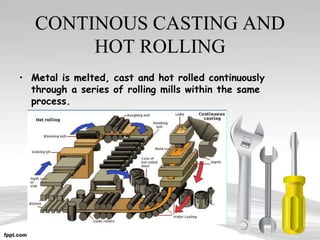

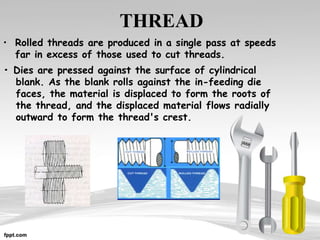

Rolling is a metal forming process that uses rolls to reduce the thickness and increase the length of metal workpieces. It can be done hot or cold. Hot rolling occurs above the metal's recrystallization temperature and results in a more uniform structure, while cold rolling occurs at room temperature and produces closer tolerances and a better surface finish. The document defines various products of rolling like billets, blooms, slabs, plates, sheets and strips based on their dimensions. It also describes different types of rolling processes like continuous, transverse, shape, ring and thread rolling as well as the types of mills used like two-high, three-high and four-high mills.