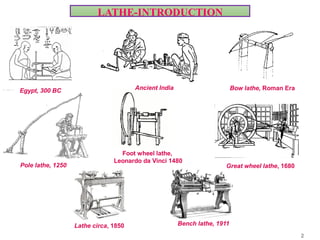

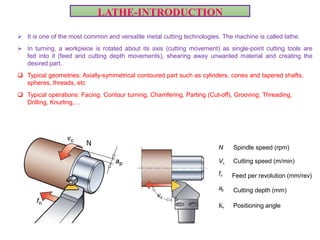

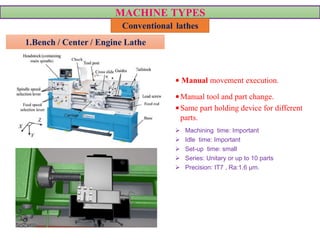

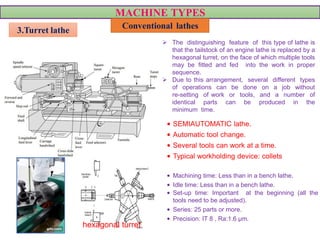

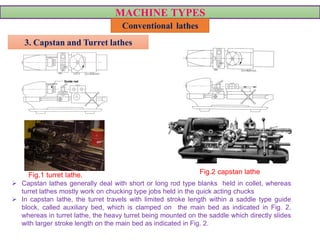

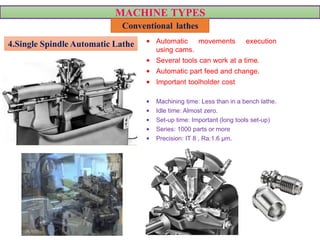

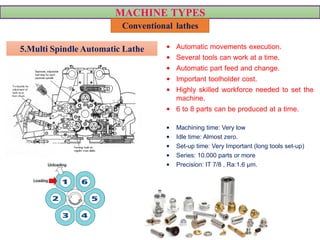

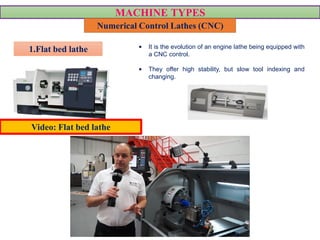

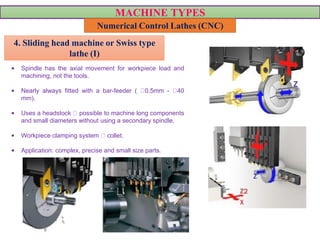

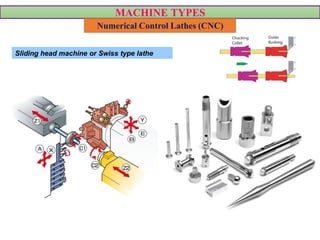

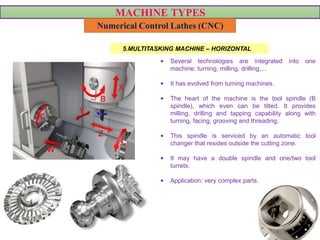

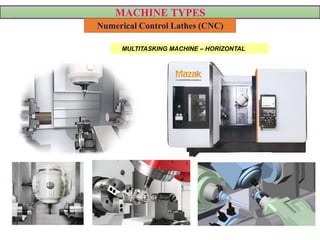

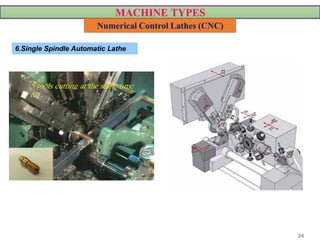

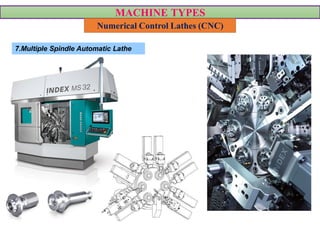

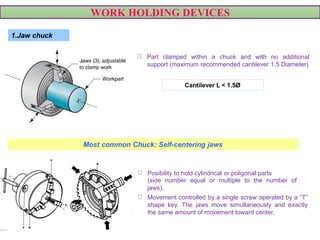

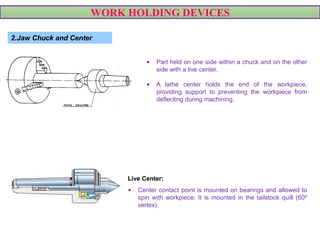

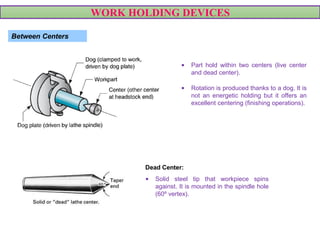

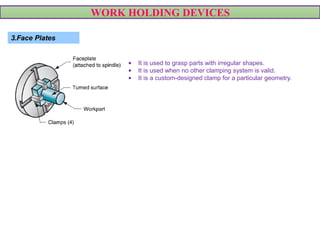

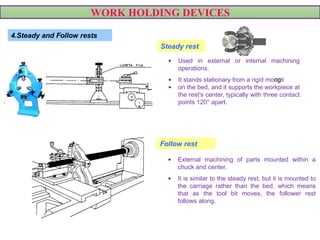

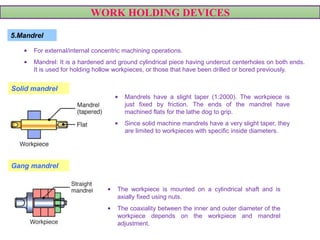

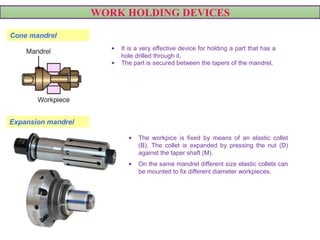

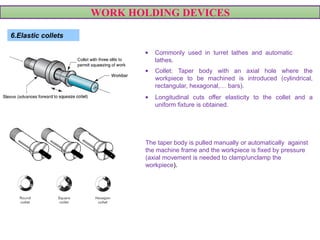

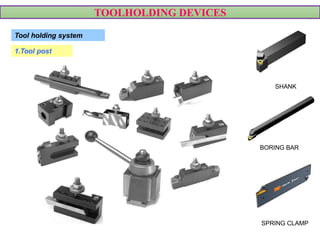

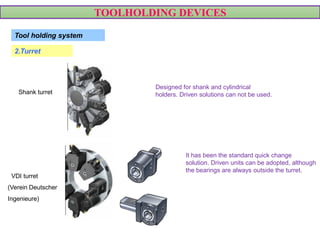

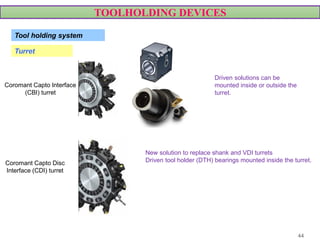

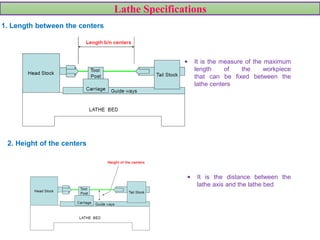

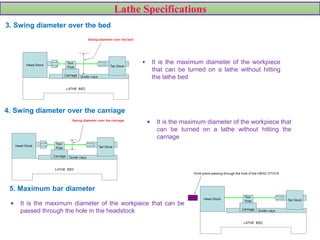

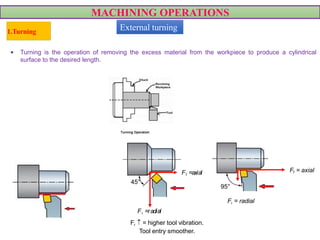

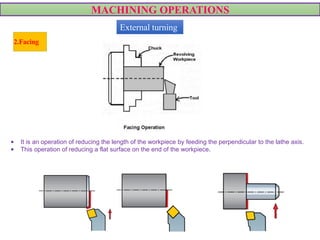

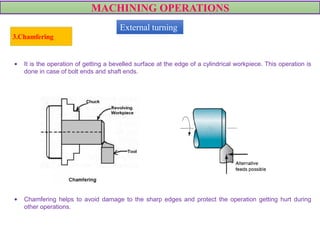

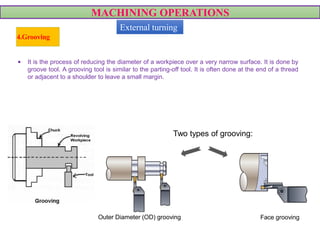

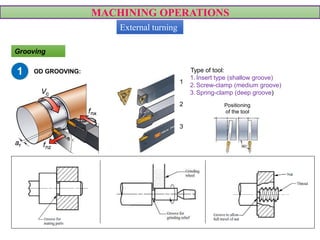

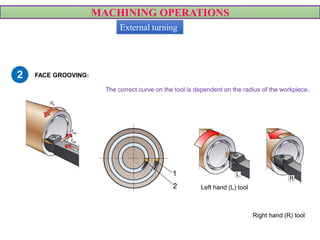

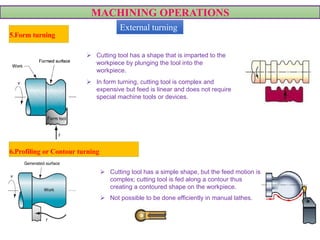

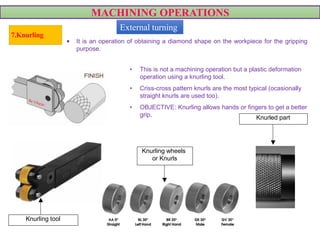

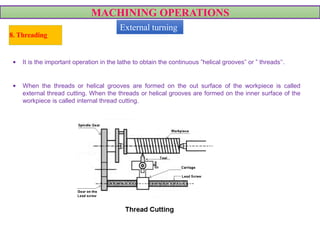

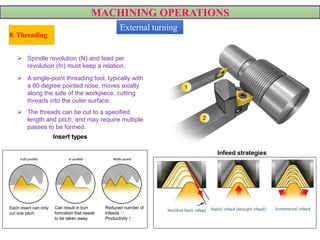

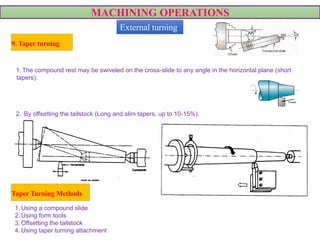

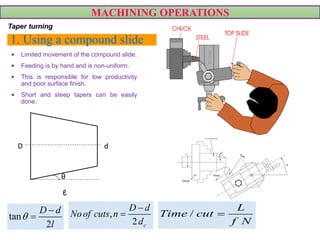

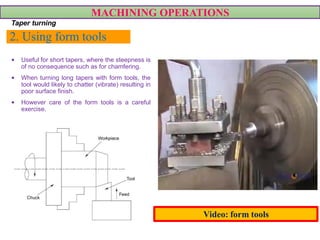

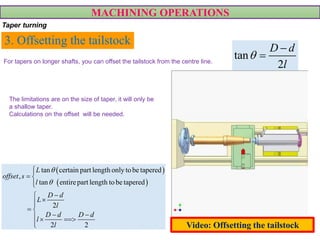

The document provides information about various types of lathes and machining operations performed on lathes. It discusses the history of lathe development from ancient times to modern CNC lathes. It describes different lathe components like beds, headstocks, toolholding devices, workholding devices and specifications. It explains common machining operations like turning, facing, grooving and threading. In under 3 sentences.