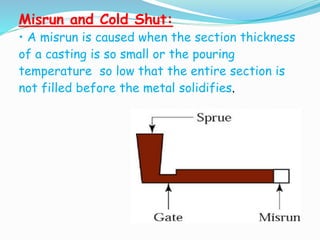

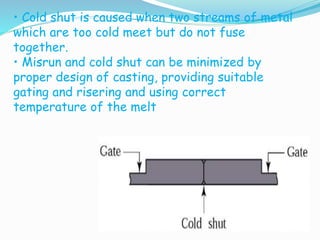

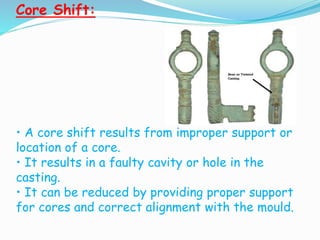

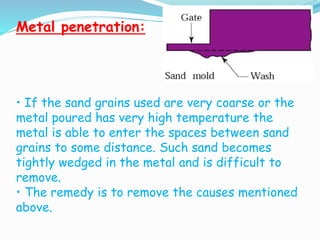

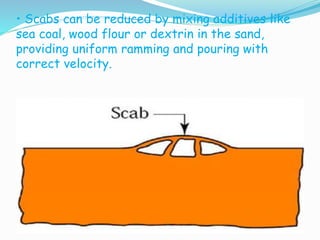

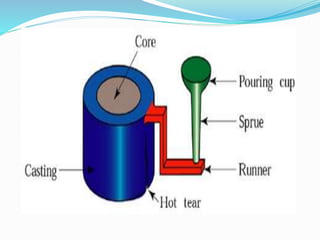

This document discusses various common defects that can occur in sand castings, their causes, and how to minimize them. It describes defects such as misruns and cold shuts caused by improper filling before solidification. Shrinkage faults result from inadequate feeding due to poor gating/risering design or solidification issues. Rat tails and buckles are caused by compressed sand layers from heat expansion. Core shifts are from improper core support. Remedies involve design improvements and controlling variables like pouring temperature and solidification.