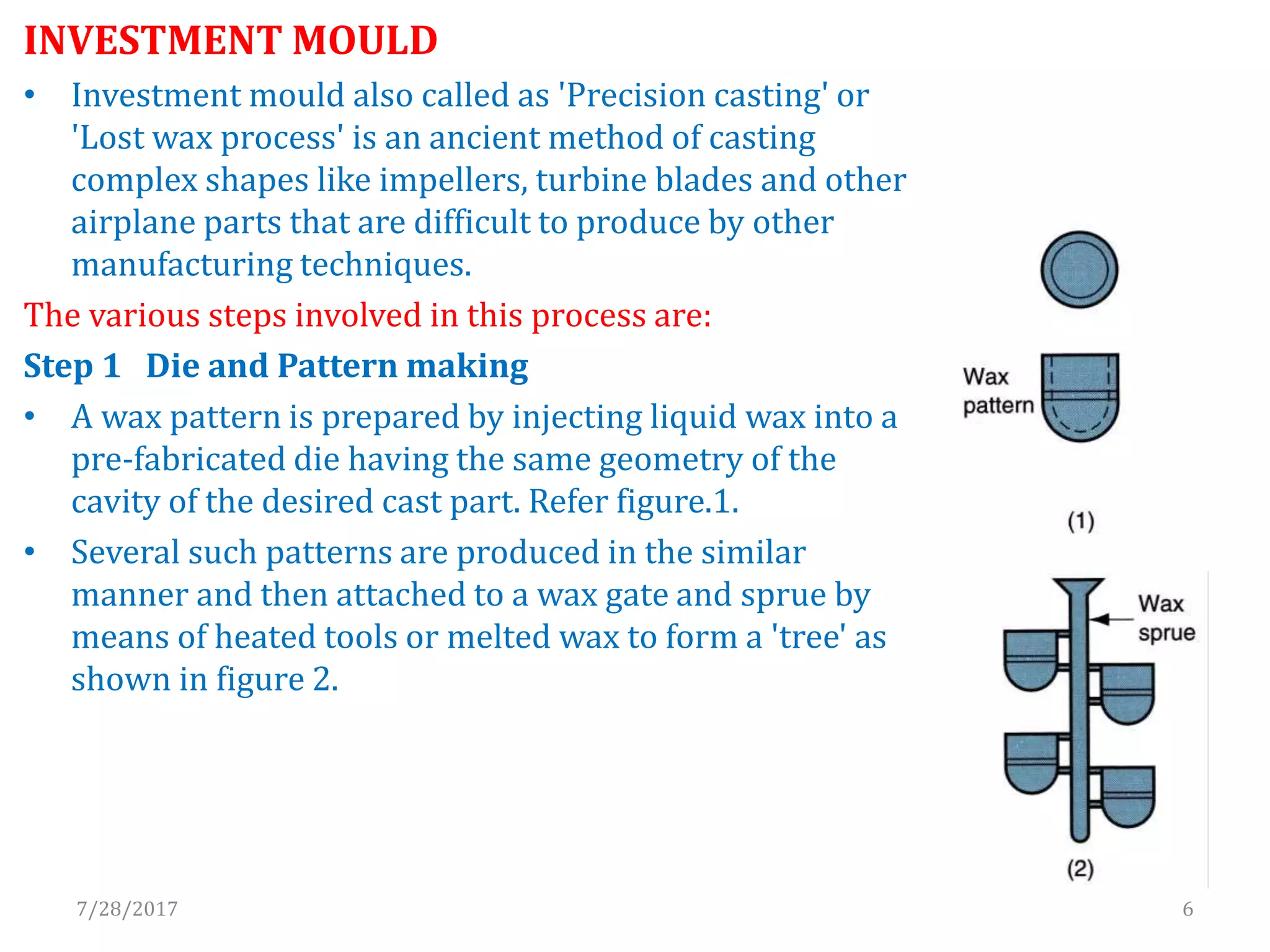

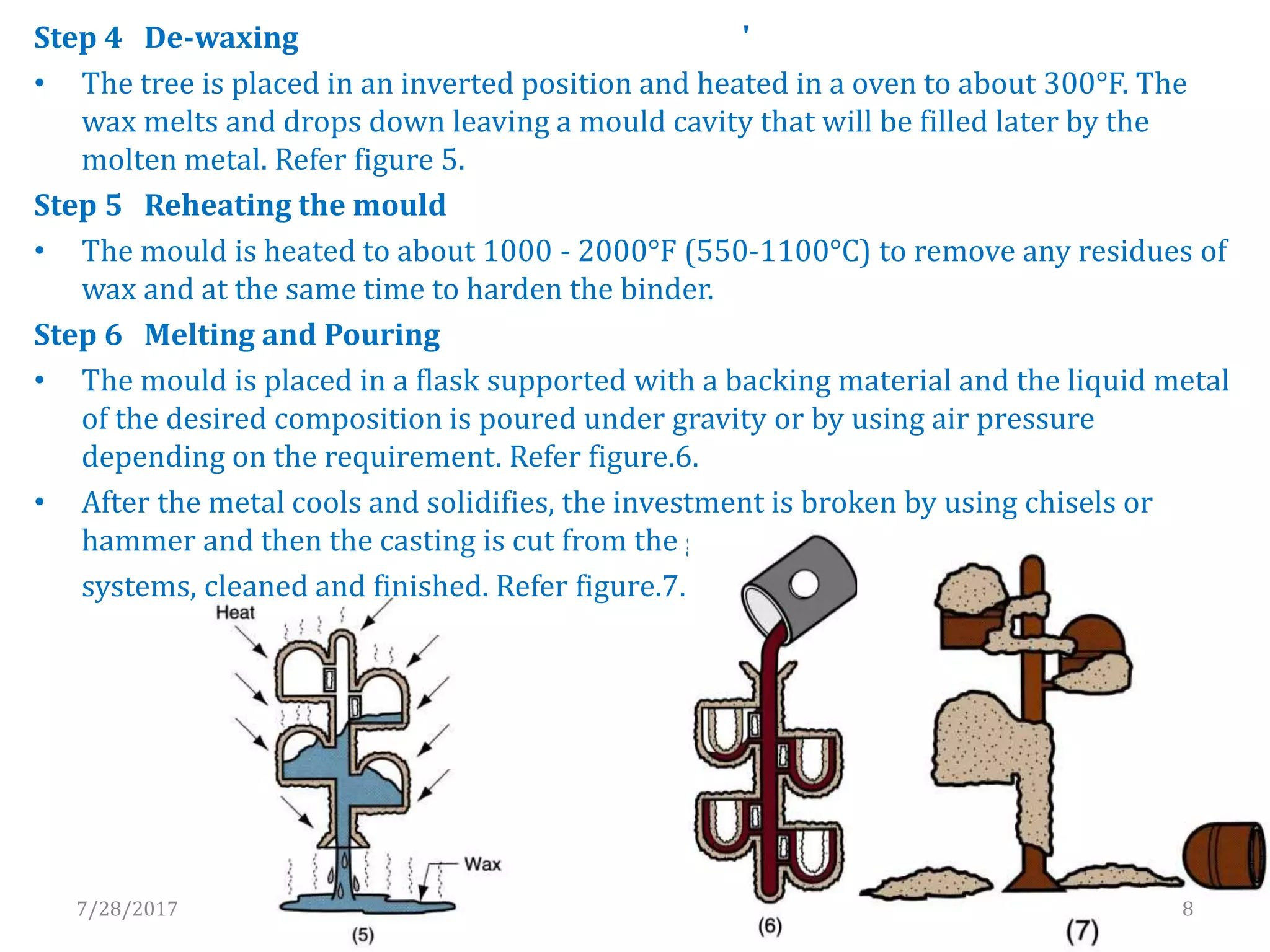

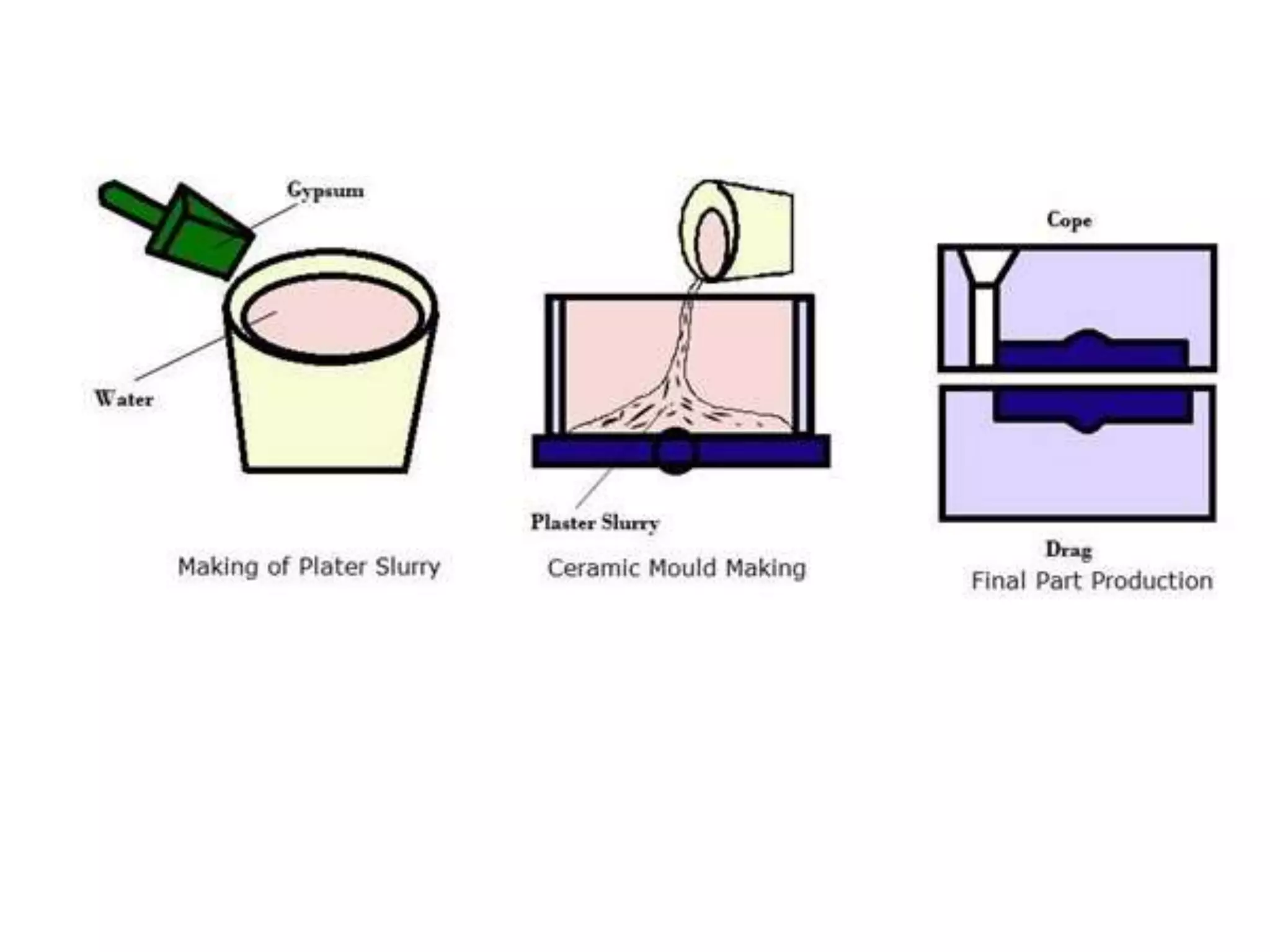

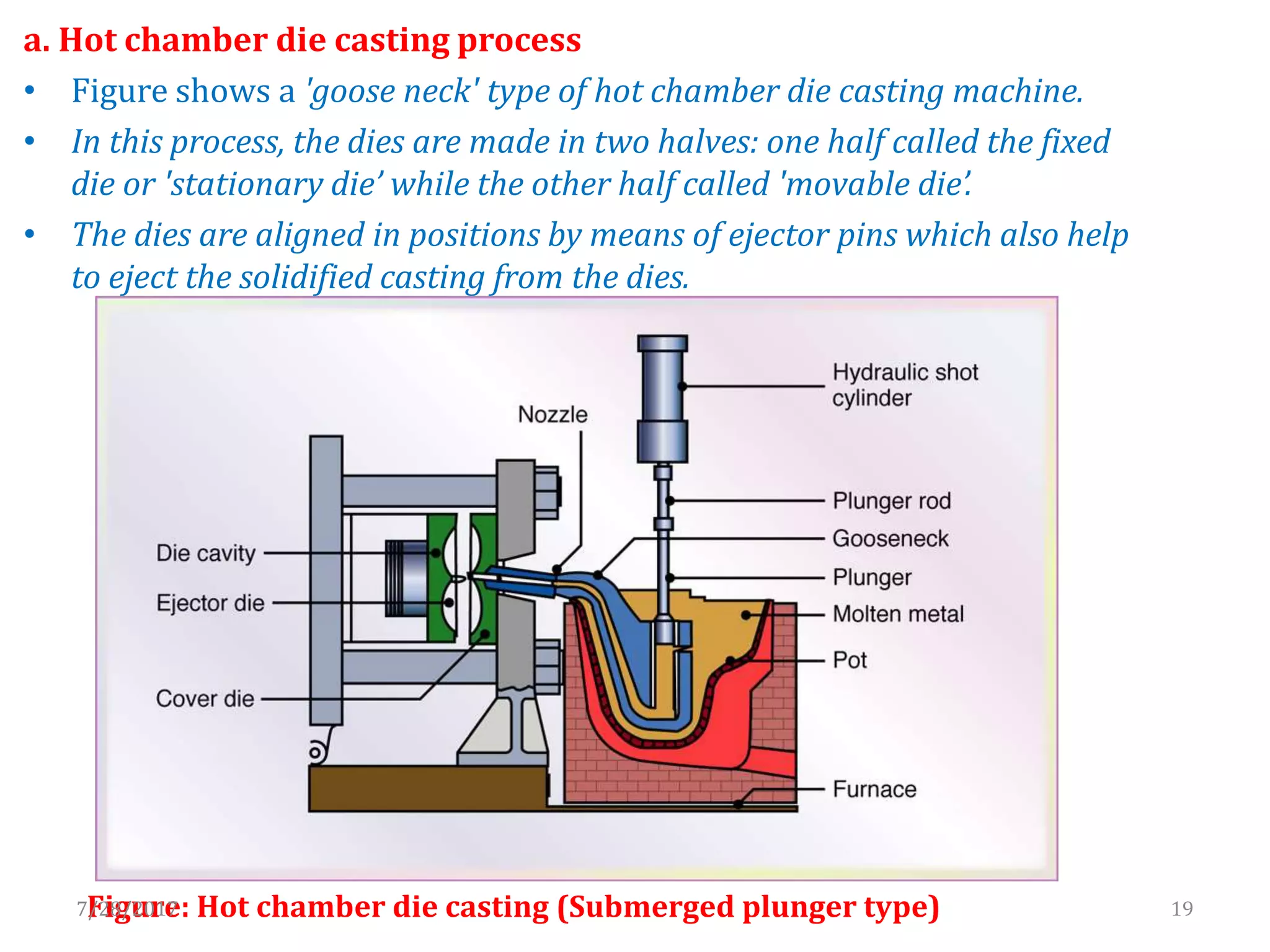

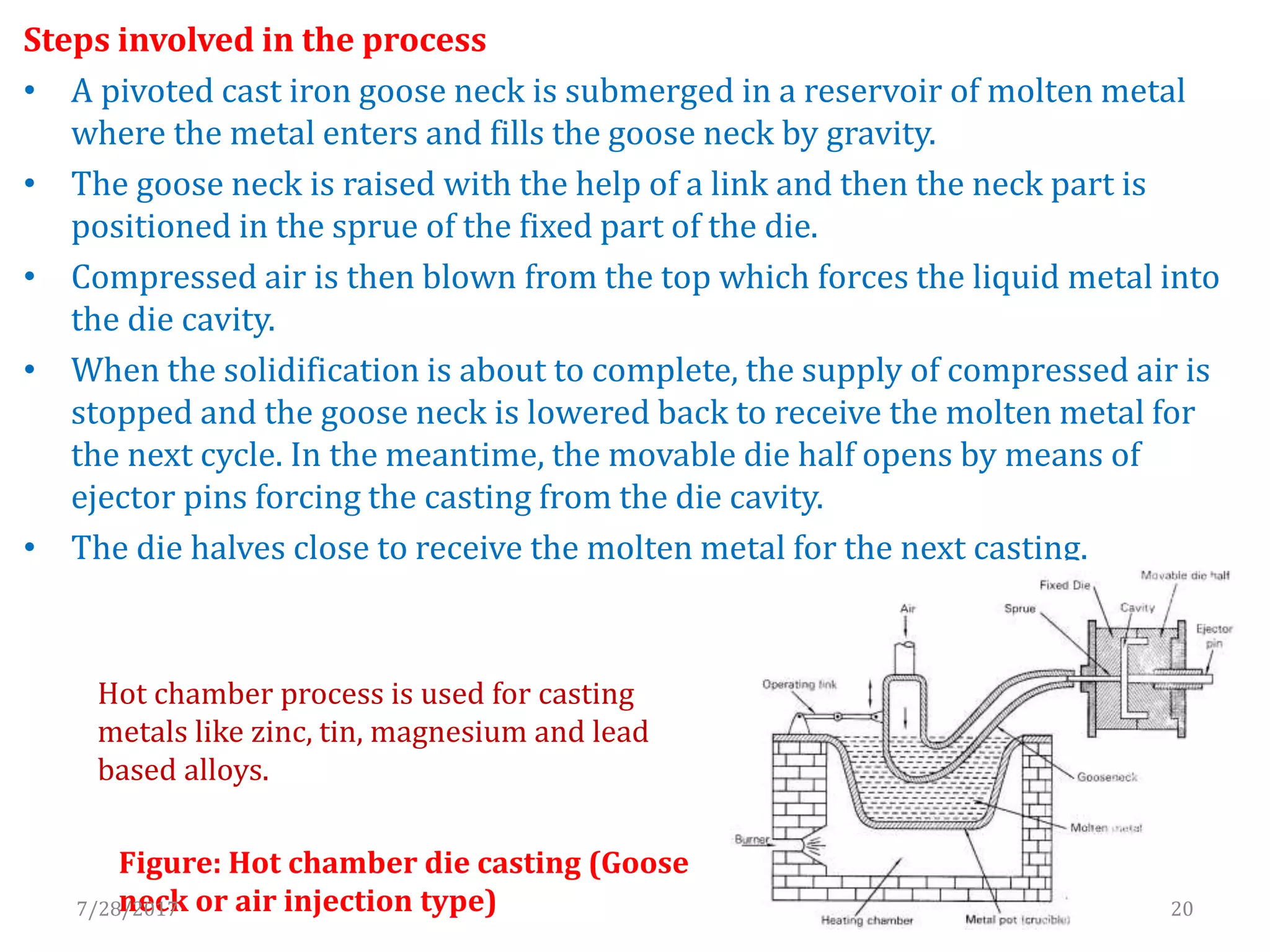

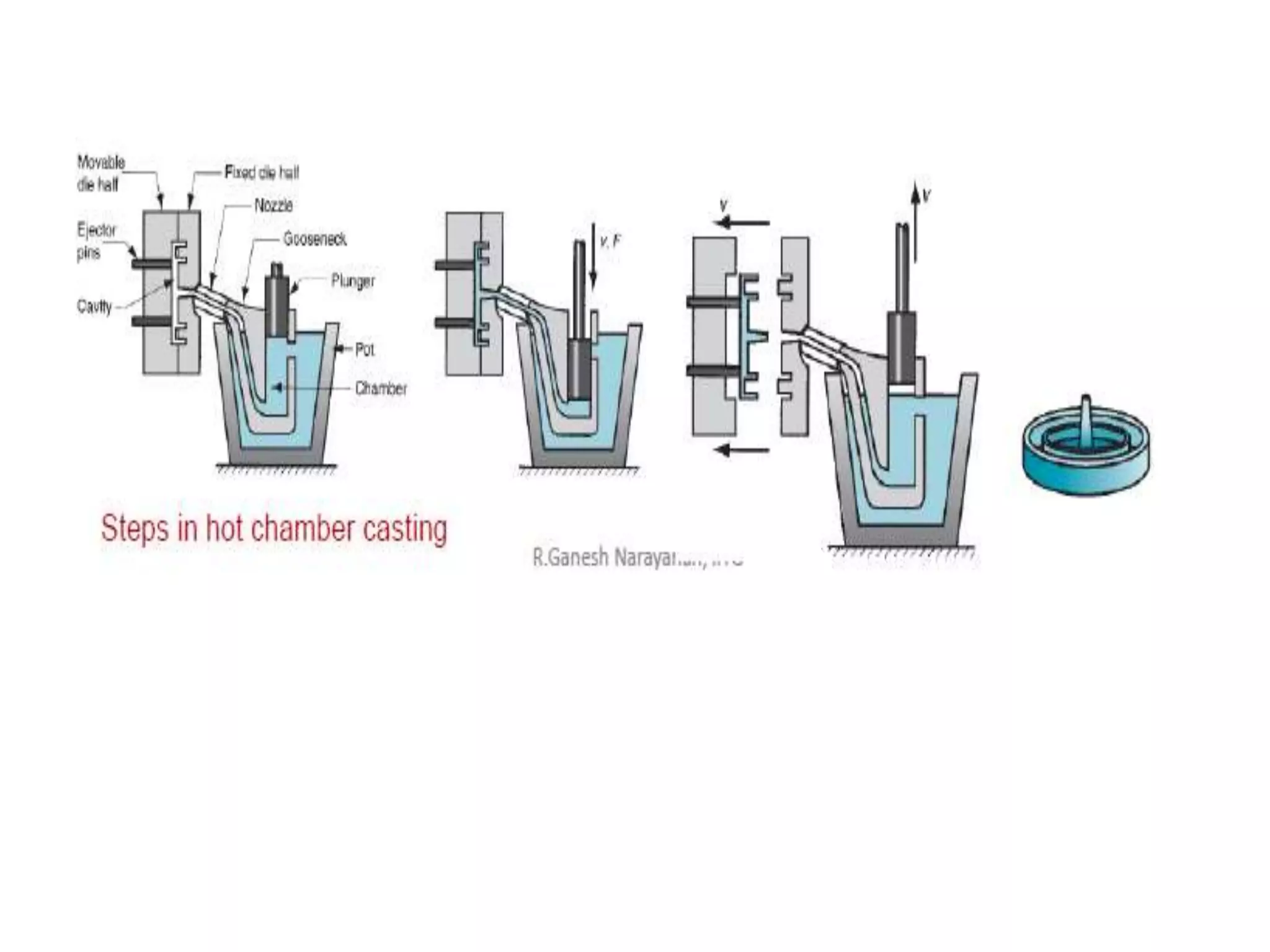

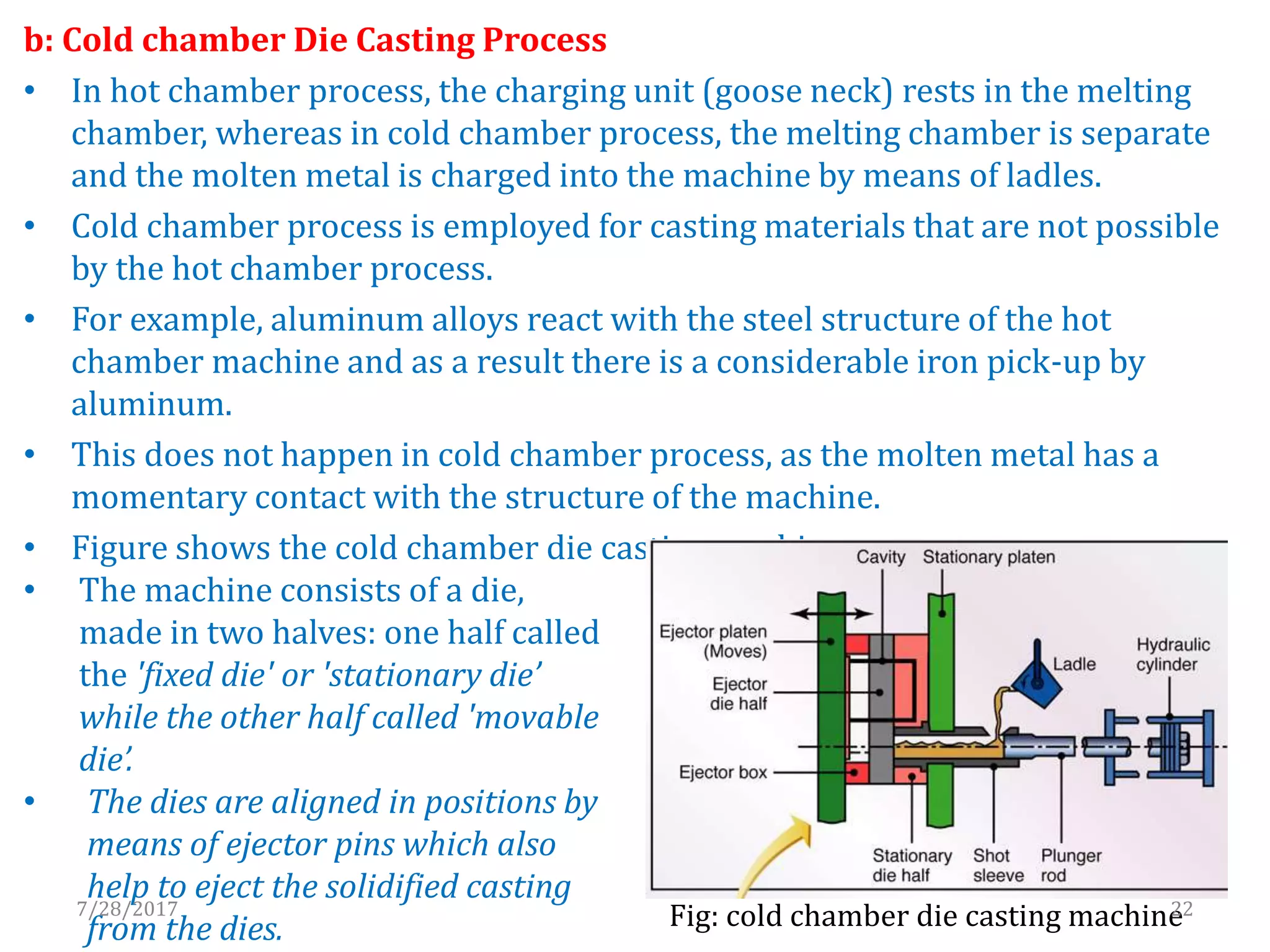

Shell moulding is an efficient and economical casting method that involves making a thin shell of sand and resin on a heated pattern. The pattern is then removed, leaving the shell to be used as a mould. Investment casting, also called lost-wax casting, is an ancient process used to produce complex shapes. It involves making a wax pattern, coating it, and then melting out the wax to leave a cavity that is filled with molten metal. Pressure die casting injects molten metal into a die under high pressure and is suitable for low melting point metals like zinc.