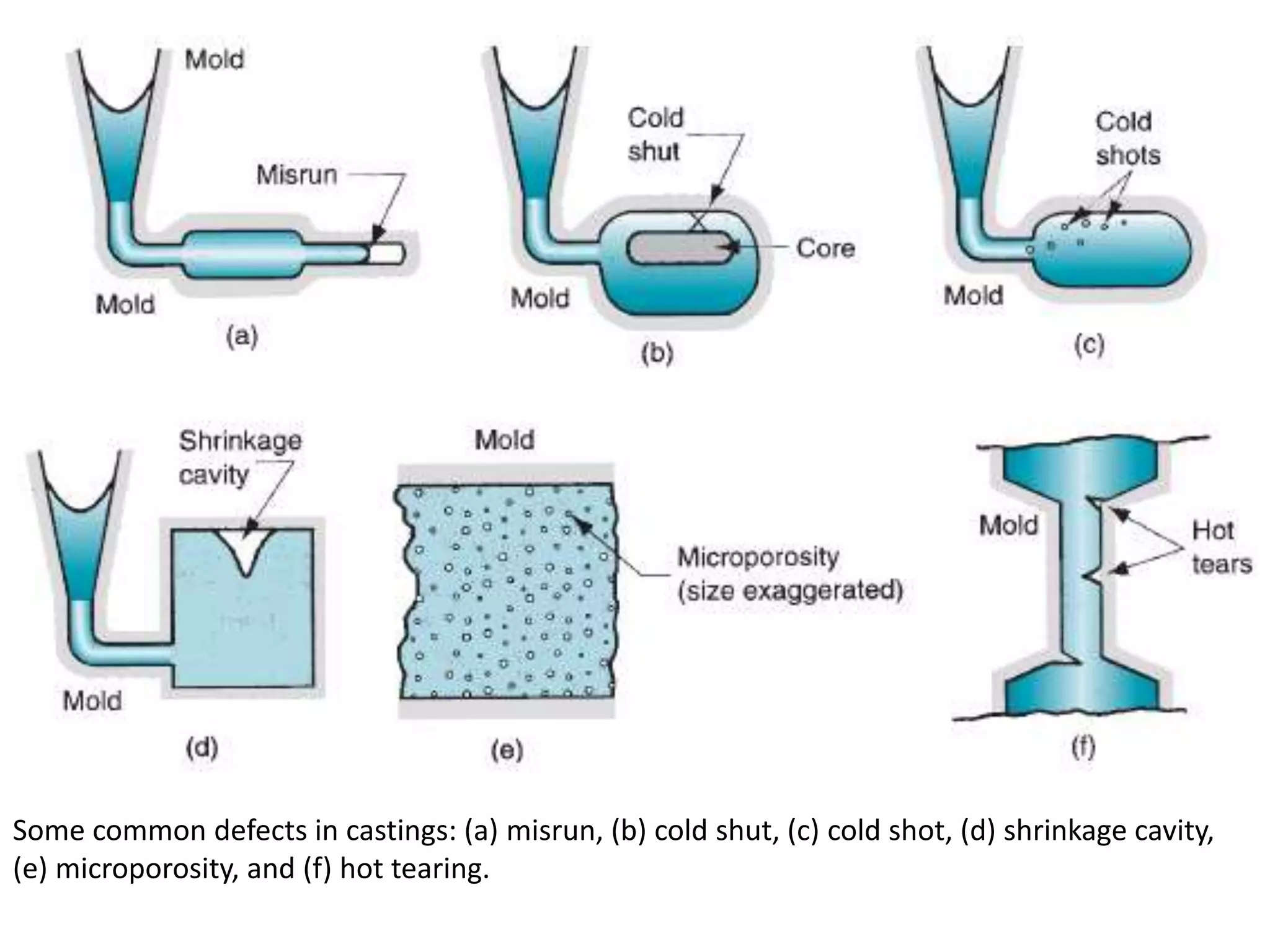

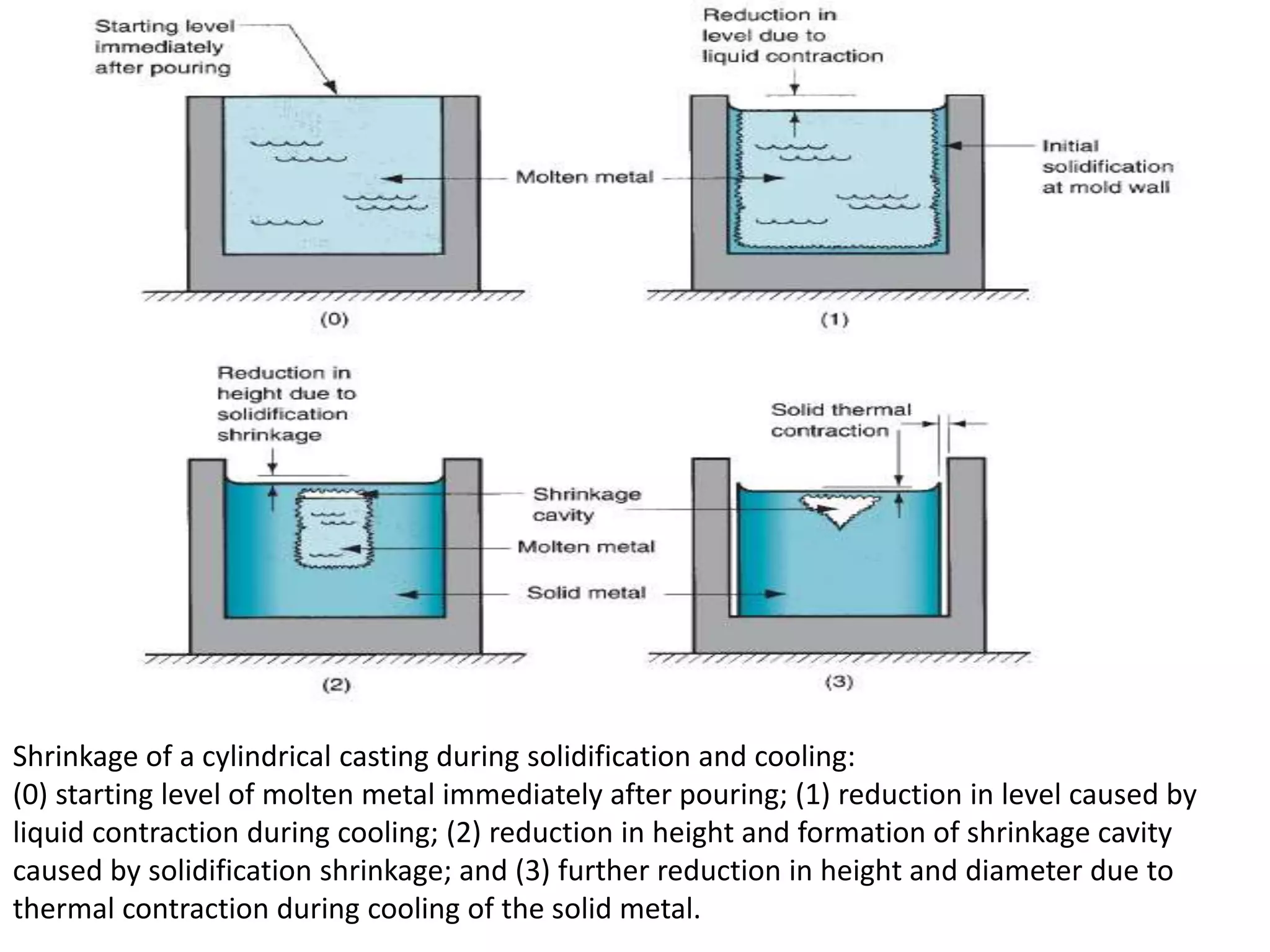

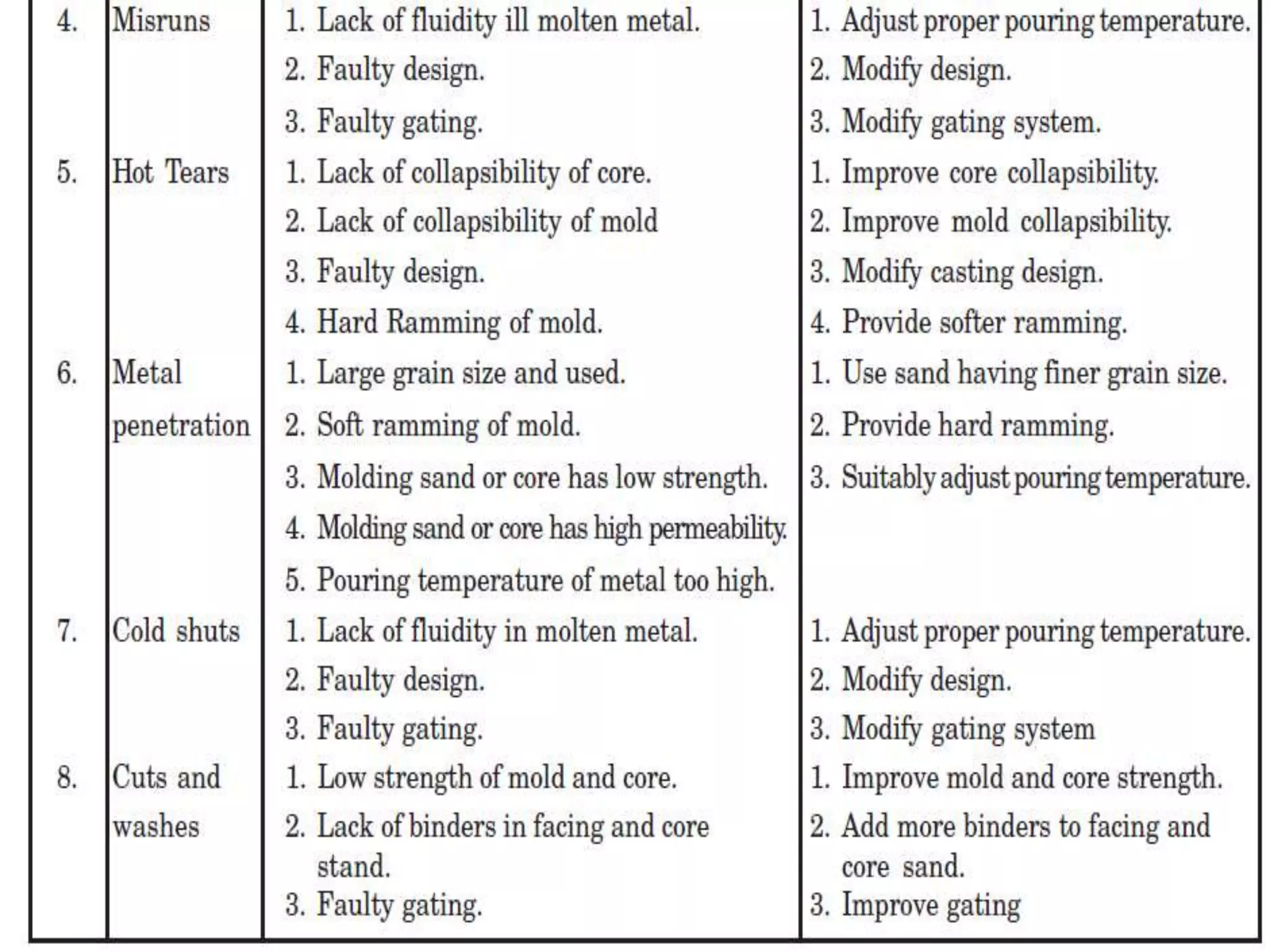

Common defects in castings include misruns caused by insufficient fluidity, pouring at too low a temperature, too slow pouring, or thin cross-sections. Cold shuts occur when two portions of metal fuse together incompletely due to premature freezing. Shrinkage cavities form from solidification shrinkage restricting the last metal to freeze, often near the top of the casting. Microporosity consists of small voids from localized shrinkage in alloy dendrites. Hot tearing occurs when a casting is restrained from contracting in an unyielding mold during solidification.