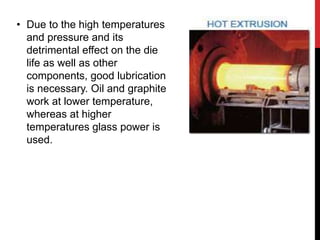

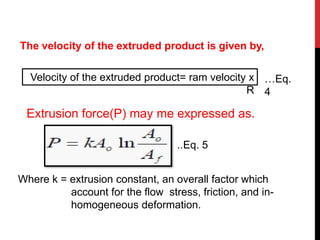

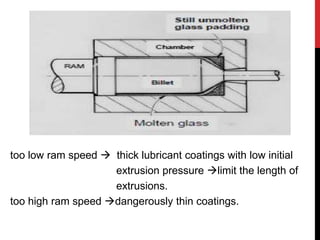

Extrusion is a process where a block of metal is reduced in cross-section by forcing it to flow through a die under high pressure. There are different types of extrusion classified by direction (direct/indirect), temperature (hot/cold), and equipment (horizontal/vertical presses). Key equipment includes presses, dies, and tools. Dies must withstand high stresses and be designed for the desired shape. Process variables like temperature, extrusion ratio, and friction affect the required extrusion force. Hot extrusion near 50-75% of melting temperature is most common to reduce deformation resistance.