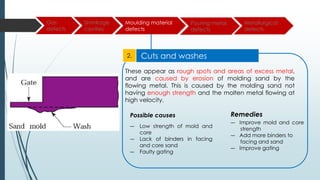

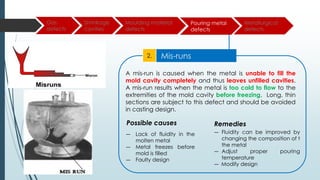

Moulding involves packing prepared moulding sand around a pattern to form a mould cavity. The pattern is then removed, leaving the cavity into which molten metal can be poured. Different types of moulding sand have various properties like permeability, flowability, and collapsibility. Defects in castings can arise from gas entrapment, shrinkage, issues with moulding materials, pouring problems, or metallurgical factors. Die casting uses high pressure to inject molten metal into metal molds, allowing for intricate, thin-walled parts to be produced at high rates. Centrifugal casting involves rotating a mold to use centrifugal force to help fill symmetrical shapes, allowing impurities to