Embed presentation

Downloaded 30 times

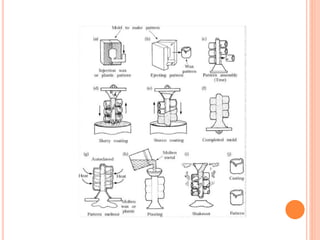

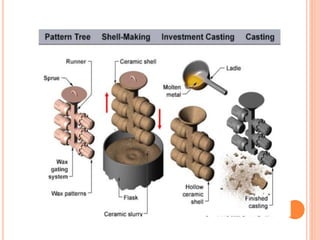

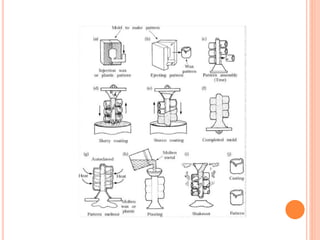

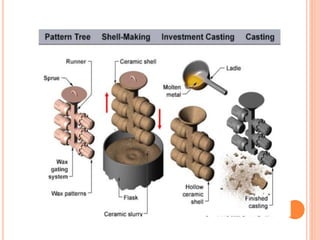

The investment casting process begins by creating wax or plastic patterns of the desired casting shape. These patterns are assembled and surrounded by a refractory slurry mold. The mold is then heated, melting out the pattern and leaving a clean cavity. Molten metal is then poured into the mold to create the casting, which is then separated from the mold. This lost wax process allows for intricate details and smooth surfaces in castings of alloys that are difficult to machine.